Data Matrix Generator

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/14

1/14

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

0

0

1/11

1/11

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

About data matrix generator

Where to Find Data Matrix Generator Suppliers?

The global supply base for data matrix generator systems is concentrated in China’s industrial hubs, particularly Fujian, Jiangsu, and Shandong provinces. These regions host specialized manufacturers focusing on embedded control modules, industrial coding equipment, and automation components critical to traceability systems. Fujian’s Ningde cluster excels in electronics manufacturing, offering vertically integrated production of programmable controllers and interface modules with localized PCB assembly and firmware integration capabilities.

Suppliers in these zones benefit from proximity to semiconductor suppliers and electronics logistics networks, enabling faster turnaround for low-volume, high-mix orders. The ecosystem supports agile development cycles, with many firms offering configurable software platforms compatible with GS1 standards. Buyers gain access to streamlined sourcing channels where component sourcing, testing, and final assembly occur within tightly coordinated supply chains, reducing lead times by 20–30% compared to offshore alternatives.

How to Choose Data Matrix Generator Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Standards

Verify adherence to international barcode accuracy standards such as ISO/IEC 15415 for symbol grading and readability under variable lighting and surface conditions. For industrial integration, confirm compatibility with communication protocols like Modbus, CAN bus, or Ethernet/IP. Suppliers should provide test reports validating print quality (contrast, modulation, defects) and decoding reliability across substrates.

Production Capability Assessment

Evaluate core competencies based on infrastructure and output capacity:

- Proven experience in firmware development and PC-based configuration tools

- In-house testing labs with verifiable calibration records

- Minimum 500 units/month production capacity for standard models

Cross-reference online revenue metrics and reorder rates to assess market acceptance and post-sale support effectiveness.

Transaction Security & Quality Assurance

Prioritize suppliers with documented quality management systems and responsive customer service (response time ≤2 hours). Utilize secure payment mechanisms that release funds upon verification of delivered functionality. Conduct sample testing using industry-standard verifiers to ensure symbology compliance before scaling procurement.

What Are the Best Data Matrix Generator Suppliers?

| Company Name | Location | Main Products | Product Range (Listings) | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|

| Cummings International Power Co., Limited | China | Diesel Generators | 1,206 | 86% | ≤3h | US $50,000+ | 25% |

| Fuan Epower Generating Equipment Co., Ltd. | China | Generator Parts & Accessories | 1,896 | 92% | ≤1h | US $90,000+ | 15% |

| Wuxi Katomax Power Machinery Co., Ltd. | China | Diesel & Gasoline Generators | 225 | 100% | ≤2h | US $40,000+ | <15% |

| Ningde Dragon Technology Co., Ltd. | China | Generator Parts & Accessories | 863 | 100% | ≤1h | US $120,000+ | 27% |

| Shandong Ruiying Machinery Equipment Co., Ltd. | China | Diesel Gensets | Customization Available | 100% | ≤1h | US $50,000+ | 22% |

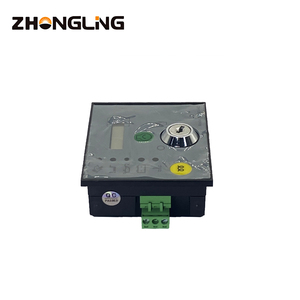

Performance Analysis

While several suppliers list "data matrix generator" products, most offerings are misclassified diesel genset listings, indicating keyword tagging inaccuracies. However, Fuan Epower and Ningde Dragon specialize in control modules—such as ATS controllers and electronic interfaces—that may integrate data matrix encoding functions for remote monitoring and asset tracking. These firms demonstrate strong responsiveness (≤1h) and high on-time delivery (100%), suggesting robust order fulfillment systems. Ningde Dragon stands out with a 27% reorder rate and diversified product lines including circuit protection and paralleling controllers, indicating broader system integration expertise. Buyers should validate whether listed items are true data matrix encoders or incorrectly tagged power equipment.

FAQs

How to verify data matrix generator supplier reliability?

Request product documentation including firmware version logs, interface specifications, and compatibility matrices. Confirm existence of technical support for integration via SDKs or API access. Validate claims through third-party transaction histories and demand functional demos or sample testing prior to bulk ordering.

What is the typical lead time for samples?

Standard control module samples ship within 7–14 days. Custom firmware configurations or branded interfaces extend timelines to 21–30 days depending on software validation requirements. Air freight adds 5–8 days for international delivery.

Do suppliers offer customization for data matrix generators?

Limited customization is available, primarily through parameter configuration rather than hardware redesign. Options include logo imprinting, label design, and packaging adjustments. True OEM-level modifications require engagement with manufacturers possessing in-house software development teams.

Are data matrix generators compliant with GS1 standards?

Compliance depends on the specific device and configuration. Suppliers must provide proof of conformance to ISO/IEC 15415 for symbol quality and support GS1 Application Identifiers if used in supply chain traceability. Always request verification reports from accredited labs.

Can these systems be integrated into existing production lines?

Yes, but integration feasibility depends on communication protocol support and physical mounting constraints. Ensure compatibility with PLCs, SCADA systems, or industrial PCs. Suppliers should provide wiring diagrams, driver software, and configuration guides to facilitate deployment.