Dc Current Sensor Producer

About dc current sensor producer

Where to Find DC Current Sensor Producers?

China remains the central hub for DC current sensor manufacturing, with key production clusters in Beijing, Wenzhou, Nanjing, Jiangyin, and Shenzhen. These regions host specialized electronics manufacturers that integrate Hall-effect technology, magnetic sensing, and precision signal conditioning into scalable production lines. The concentration of component suppliers—particularly in Zhejiang and Guangdong provinces—enables vertically integrated operations, reducing material lead times by 25–40% compared to non-specialized regions.

Suppliers in these industrial zones benefit from mature supply chains for ferrite cores, semiconductor ICs, and molded enclosures, supporting both open-loop and closed-loop sensor architectures. Production capabilities range from small-batch prototyping to high-volume runs exceeding 10,000 units per month. Buyers gain access to flexible sourcing options, including split-core designs, AC/DC detection, and analog output configurations (0–5V, 4–20mA). Typical advantages include MOQs as low as 1–3 pieces for evaluation, lead times of 7–15 days for sample orders, and cost efficiencies driven by localized assembly and testing infrastructure.

How to Choose DC Current Sensor Producers?

Effective supplier selection requires a structured assessment across technical, operational, and transactional dimensions:

Technical & Design Capability

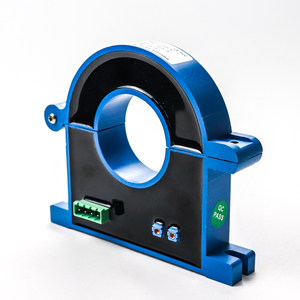

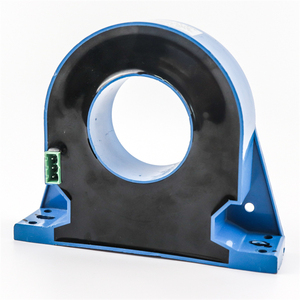

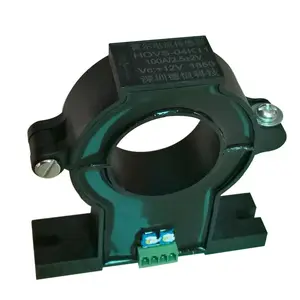

Confirm whether the producer supports required measurement ranges (e.g., 100A–2000A), accuracy levels (±1% to ±0.5%), and output types (voltage or current signals). Suppliers offering Hall-effect transducers, such as those producing NJXSE and KCT series models, typically provide higher linearity and temperature stability. Verify compatibility with DC microgrid, EV charging, or solar inverter applications through datasheet validation.

Production & Quality Assurance

Evaluate operational metrics indicative of reliability:

- On-time delivery rates exceeding 95%

- Response times under 5 hours for technical inquiries

- In-house testing protocols for insulation resistance, thermal drift, and long-term stability

Prioritize producers with CE, RoHS, and ISO 9001 compliance documentation, particularly for export to EU and North American markets.

Procurement Flexibility

Assess minimum order quantities (MOQs) and pricing scalability. Leading producers offer tiered pricing starting below $5/unit at 100-piece volumes. Confirm customization support for mechanical form factors (split-core vs. solid-core), voltage isolation ratings (up to 500V), and calibration certificates. Transaction safeguards such as verified revenue histories and reorder rate transparency help mitigate counterparty risk.

What Are the Top DC Current Sensor Producers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Key Product Lines | Min. Order Range |

|---|---|---|---|---|---|---|---|---|

| Beijing Yaohua Dechang Electronic Co., Ltd. | Beijing, CN | Transformers (1169), Current Sensors (153) | US $20,000+ | 94% | ≤11h | 17% | YHDC Series (300A–2000A) | 1 piece |

| WENZHOU HEYI ELECTRICAL CO., LTD. | Wenzhou, CN | Current Sensors (333), Transformers (231) | US $140,000+ | 95% | ≤5h | 26% | KCT-36L, HYCA Series | 1–3 pieces |

| Nanjing Up Electronic Technology Co., Ltd. | Nanjing, CN | Transformers (259), Current Sensors (53) | US $180,000+ | 98% | ≤2h | 18% | NJXSE-B2A, K11A, K14D | 1–3 pieces |

| Jiangyin Spark Electronic Technology Co., Ltd. | Jiangyin, CN | Transformers (529), Current Sensors (20) | US $30,000+ | 94% | ≤3h | 20% | Hall-effect Split-Core Sensors | 2–10 pieces |

| Shenzhen Winshine Technology Co., Ltd. | Shenzhen, CN | Current Sensors (19), Magnetic Sensors (1) | US $100+ | 100% | ≤1h | <15% | JCT-ACS, B3R Closed-Loop | 50–100 pieces |

Performance Analysis

Wenzhou Heyi and Nanjing Up Electronics demonstrate strong balance between volume capability and responsiveness, with on-time delivery rates of 95% and 98%, respectively. Shenzhen Winshine stands out for perfect on-time performance (100%) and sub-hour response times, though its lower reorder rate suggests room for customer retention improvement. Beijing Yaohua Dechang offers broad product diversity with over 150 current sensor listings, ideal for buyers seeking application-specific variants. For high-volume procurement, prioritize suppliers with online revenues above US $100,000 and proven closed-loop transducer production, which ensures tighter accuracy and lower drift in critical energy monitoring systems.

FAQs

How to verify DC current sensor producer reliability?

Cross-check certifications (CE, RoHS) and validate test reports for linearity, hysteresis, and isolation voltage. Request sample units for bench testing against IEC 61869-10 standards. Analyze supplier response consistency and technical depth during pre-sales engagement.

What is the typical sampling timeline?

Standard samples ship within 5–10 days. Custom configurations involving new core molds or calibration curves may require 15–25 days. Air freight adds 3–7 days for international delivery.

Do producers support global shipping?

Yes, most manufacturers offer EXW, FOB, or CIF shipping terms with express carriers or sea freight. Confirm packaging standards for shock-sensitive components and compliance with destination electrical safety regulations.

Are free samples available?

Sample policies vary: some suppliers waive fees for qualified buyers committing to future bulk orders. Others charge partial cost recovery, typically 30–70% of unit price, refundable upon order placement.

How to request product customization?

Submit detailed specifications including current range, supply voltage, output signal type, mounting style, and environmental rating (IP65, etc.). Reputable producers will respond with revised datasheets, 3D drawings, or prototype timelines within 72 hours.