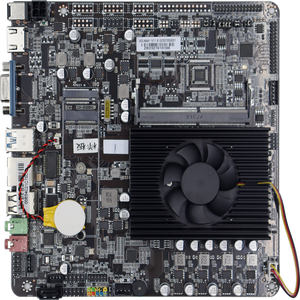

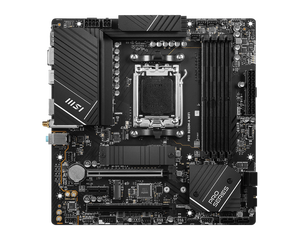

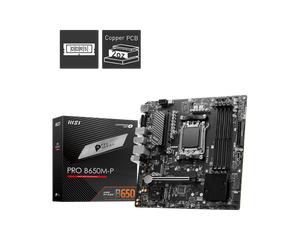

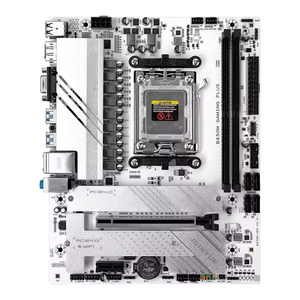

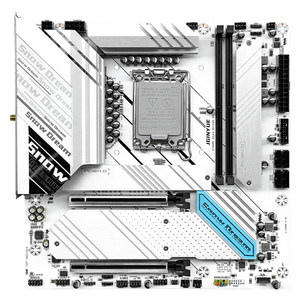

Ddr5 Mobo

Top sponsor listing

Top sponsor listing

1/3

1/3

0

0

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

0

0

1/1

1/1

0

0

1/3

1/3

1/3

1/3

1/25

1/25

1/2

1/2

1/3

1/3

About ddr5 mobo

Where to Find DDR5 Motherboard Suppliers?

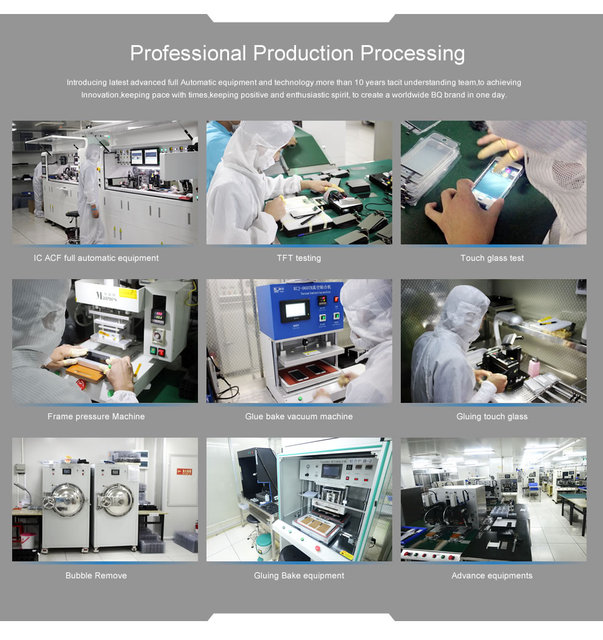

Asia remains the central hub for DDR5 motherboard manufacturing, with production clusters concentrated in Guangdong and Jiangsu provinces, China. These regions host over 70% of global PCB assembly and advanced chipset integration facilities, supported by mature semiconductor supply chains and high-capacity SMT (Surface Mount Technology) lines. Guangdong, particularly Shenzhen, benefits from proximity to IC distributors and logistics gateways, enabling rapid component sourcing and export processing. Jiangsu’s industrial parks integrate wafer testing, packaging, and board-level validation under one ecosystem, reducing inter-facility delays.

Manufacturers in these zones operate vertically integrated production systems—spanning PCB lamination, BGA (Ball Grid Array) mounting, BIOS programming, and burn-in testing—allowing batch fulfillment within compressed timelines. Buyers access economies of scale through shared infrastructure: automated optical inspection (AOI) stations, environmental stress screening chambers, and ESD-protected assembly floors. Typical advantages include lead times of 25–40 days for standard SKUs, 18–25% lower unit costs compared to EU/US-based producers, and flexibility for both OEM configurations and reference design adaptations.

How to Choose DDR5 Motherboard Suppliers?

Implement structured evaluation protocols to mitigate technical and operational risks:

Quality & Compliance Verification

Confirm adherence to IPC-A-610 Class 2 standards for electronic assemblies as baseline quality assurance. For international distribution, validate CE, FCC, and RoHS certifications covering electromagnetic compatibility and hazardous substance restrictions. Request test reports for signal integrity (via eye diagram analysis), power delivery stability under load (VRM thermal performance), and BIOS/UEFI compatibility with current-gen CPUs.

Production Capacity Assessment

Evaluate key infrastructure indicators:

- Minimum 3,000m² cleanroom facility with ESD controls

- Dual-line SMT placement machines supporting 01005 package components

- In-house firmware flashing and POST validation stations

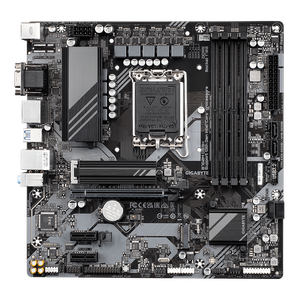

Correlate factory specifications with documented output capacity—target suppliers capable of 10,000+ units/month for mainstream chipsets (e.g., Intel Z790, AMD X670).

Procurement Risk Mitigation

Utilize milestone-based payment structures with holdbacks until post-arrival functional verification. Review supplier track records via verified transaction histories, prioritizing those with documented RMA processes and field failure rates below 0.8%. Pre-shipment sampling is critical—conduct boot cycles across multiple CPU/memory combinations and stress-test PCIe lane allocation before volume orders.

What Are the Best DDR5 Motherboard Suppliers?

No verified suppliers are currently listed in the available dataset for DDR5 motherboards. Procurement professionals should initiate supplier discovery through industry trade databases, electronics manufacturing expos (e.g., Electronica, HK Electronics Fair), and direct engagement with ODMs operating in Dongguan and Suzhou. Focus on partners disclosing full traceability of core components—including VRM MOSFETs, PCH chips, and DDR5 memory controllers—from authorized distributors or Tier-1 sources like Intel, AMD, and Micron.

Performance Analysis

In absence of active supplier data, due diligence must emphasize transparency in bill-of-materials (BOM), real-time production monitoring access, and compliance documentation. Leading-tier manufacturers typically maintain on-time delivery rates above 97%, support MOQs as low as 50 units for initial trials, and offer customization options including BIOS lockdown, MAC address pre-registration, and heatsink branding. Prioritize suppliers providing detailed gerber file reviews and impedance-controlled stackup designs during technical onboarding.

FAQs

How to verify DDR5 motherboard supplier reliability?

Cross-validate ISO 9001 and IATF 16949 certifications with accredited bodies. Request audit trails covering component lot numbers, reflow profile logs, and AOI false-call rates. Assess long-term reliability through HALT (Highly Accelerated Life Testing) summaries and customer return data across 6–12 month usage periods.

What is the average sampling timeline?

Standard sample builds require 12–18 days, inclusive of PCB fabrication, component procurement, and functional testing. Custom variants with modified VRM layouts or additional M.2 slots extend to 25–30 days. Air freight delivery adds 5–9 days depending on destination region.

Can suppliers ship DDR5 motherboards worldwide?

Yes, qualified manufacturers manage global shipments under EXW, FOB, or DDP terms. Confirm compliance with import regulations regarding static-sensitive packaging, customs classification (HS Code 8537.10), and voltage-specific labeling where applicable. Sea freight consolidation is cost-optimal for container loads exceeding 500 units.

Do manufacturers provide free samples?

Sample policies vary by order intent. Reputable suppliers may waive fees for qualified buyers committing to volume production runs (typically ≥500 units). Otherwise, expect to cover material and handling costs, generally ranging from $80–$150 per unit depending on chipset complexity.

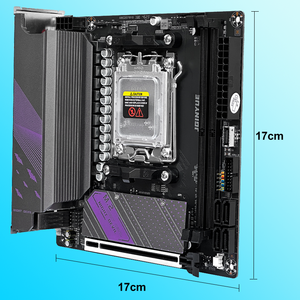

How to initiate customization requests?

Submit detailed requirements including target chipset, form factor (ATX/mATX/ITX), PCIe topology, onboard connectors, and thermal design power (TDP) thresholds. Established ODMs respond with schematic reviews, layout proposals, and 3D mechanical drawings within 5–7 business days, followed by prototype delivery in 3–4 weeks.