Dice Display Producer

CN

CN

About dice display producer

Where to Find Dice Display Producers?

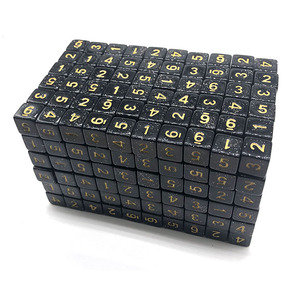

China is the central hub for dice display manufacturing, with a concentrated supplier base in Shenzhen and surrounding Guangdong regions. These areas host specialized plastic and acrylic fabrication clusters that support high-volume production of gaming accessories. The ecosystem benefits from vertically integrated supply chains—encompassing resin molding, laser engraving, packaging, and logistics—allowing manufacturers to maintain tight control over cost, quality, and delivery timelines.

Suppliers typically operate dedicated production lines for injection-molded and cast-resin dice, along with custom display solutions such as magnetic acrylic cases and polyhedral storage boxes. Average monthly output capacity among active producers ranges from 500,000 to over 2 million units, depending on facility scale. Materials commonly used include PMMA (acrylic), ABS, polycarbonate, and epoxy resin, with processing techniques like CNC cutting, screen printing, UV coating, and electrophoresis finishing widely available.

How to Choose Dice Display Suppliers?

Procurement decisions should be guided by objective evaluation criteria focused on production capability, quality consistency, and transaction reliability.

Manufacturing & Customization Capability

Verify suppliers have in-house tooling and molding equipment to support custom designs. Key indicators include availability of mold-making, multi-color printing, engraving, and liquid-core encapsulation processes. Leading producers offer full customization across size (6mm–36mm standard), color gradients, logo imprinting, and packaging design. Minimum order quantities (MOQs) vary significantly—from 10 pieces for niche premium items to 30,000+ for bulk commodity dice.

Quality Control Metrics

Assess performance using verifiable operational data:

- On-time delivery rate exceeding 94% indicates reliable logistics execution

- Reorder rates above 25% reflect customer satisfaction and product consistency

- Average response time under 3 hours demonstrates operational responsiveness

- Documented use of AI-driven proofing and graphic validation systems reduces error rates in custom orders

Certifications such as ISO 9001 are not explicitly listed but can be inferred through consistent quality metrics and structured workflows observed in top-tier suppliers.

Transaction Risk Mitigation

Prioritize suppliers with transparent digital transaction histories and clear pricing structures. Use incremental ordering strategies—starting with sample batches—to validate material quality and print accuracy before scaling. Confirm packaging durability for international shipping, especially for fragile resin or magnetic-display configurations.

What Are the Top Dice Display Producers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Notable MOQ Range |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Hairan Digital Co. Ltd | Shenzhen, CN | Dice Displays, Acrylic Cases, DnD Sets | US $370,000+ | 94% | ≤1h | 34% | Engraving, AI files, color patterns, molds, labels, resin types, painting, logos, liquid core | 20–1000 units |

| Shenzhen Jms Crafts Ltd | Shenzhen, CN | Polyhedral Dice, Storage Cases, Paper Boxes | US $650,000+ | 95% | ≤4h | 25% | Color, material, size, logo, packaging, graphics | 10–1000 units |

| China Dice Interactive Entertainment Technology (Shenzhen) Co., Ltd. | Shenzhen, CN | Printed Resin Dice, Mini Dice, Game Components | US $3,000+ | 100% | ≤3h | 20% | Custom printing, logo, panel design | 1–500 units |

| Shenzhen Sammyhung Electronic Co., Ltd. | Shenzhen, CN | Custom Dice, RPG Sets, Transparent Dice | US $150,000+ | 90% | ≤5h | 34% | Limited details; supports advertising and precise engraving | 200–2000 units |

| Taishan Yexin Plastic Products Packing Co., Ltd. | Taishan, CN | Plastic Dice, Acrylic D6, Bulk Dice | US $1,000+ | 100% | ≤5h | <15% | Color, size, customer-specific design | 5,000–30,000 units |

Performance Analysis

Shenzhen-based producers dominate in responsiveness and customization depth, with Hairan Digital and Jms Crafts offering robust capabilities backed by high reorder rates and strong online revenue. Hairan Digital stands out for its extensive design flexibility, including liquid-core and electrophoresis finishes. Jms Crafts leads in volume-ready polyhedral sets with competitive MOQs starting at 10 units. China Dice Interactive achieves perfect on-time delivery despite lower revenue, suggesting lean operations ideal for small-batch prototyping. Taishan Yexin serves high-volume buyers with ultra-low-cost options, though limited reorder activity may indicate less focus on long-term client retention. For buyers requiring rapid turnaround and design iteration, prioritize suppliers with sub-3-hour response times and AI-assisted proofing workflows.

FAQs

What materials are used in dice display production?

Common materials include transparent acrylic (PMMA) for display cases, ABS and polystyrene for standard dice, and epoxy resin for premium engraved or glow-in-the-dark variants. Magnetic layers are often embedded in acrylic housings for secure closure.

What is the typical lead time for custom dice displays?

Standard orders take 15–25 days after sample approval. Complex customizations involving multi-layer engraving, unique resins, or special packaging may extend lead times to 35 days. Rush production is possible with expedited fees.

Can I request free samples?

Sample policies vary. Many suppliers provide paid samples ($5–$20) applicable toward future orders. Truly free samples are rare but may be offered for large projected volumes or strategic partnerships.

Do these producers support private labeling and OEM packaging?

Yes, all listed suppliers offer OEM services including custom logos, branded packaging, and tailored instruction inserts. Capabilities range from simple label application to full box design and assembly.

How are quality issues resolved post-shipment?

Buyers should establish clear acceptance criteria before production. Most suppliers accept returns or replacements for defects in material or workmanship if reported within 14–30 days. Use platform-backed transaction protection where available to ensure recourse.