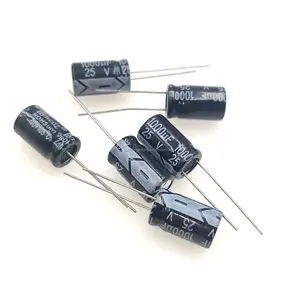

Digikey Electrolytic Capacitor

About digikey electrolytic capacitor

Where to Find Electrolytic Capacitor Suppliers?

China remains a dominant force in the global supply of electrolytic capacitors, with key manufacturing clusters concentrated in Guangdong and Liaoning provinces. Shenzhen, a hub for electronics component production, hosts vertically integrated facilities specializing in aluminum and solid-state electrolytic capacitors. These suppliers benefit from proximity to semiconductor packaging plants, PCB assembly lines, and logistics gateways like Shekou Port, enabling rapid prototyping and export fulfillment. Dongguan and Liaoning-based manufacturers focus on high-voltage and industrial-grade units used in power supplies, welding equipment, and energy storage systems.

The region’s ecosystem supports both standardized and customized capacitor production, leveraging mature supply chains for aluminum foil, electrolytes, and sealing rubber. This integration reduces material procurement lead times by 20–30% compared to non-specialized regions. Buyers gain access to flexible MOQs—from single-piece sampling to bulk container loads—with typical production cycles ranging from 7 to 21 days depending on customization complexity. Cost efficiencies are further enhanced by localized testing infrastructure and automated winding/sealing processes that maintain consistency across batches.

How to Choose Electrolytic Capacitor Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

Confirm adherence to international standards such as IEC 60384-1 for capacitance tolerance and ripple current ratings. While explicit certification data is limited in available profiles, prioritize suppliers demonstrating consistent on-time delivery (>93%) and low defect rates inferred from reorder metrics. For applications requiring environmental compliance, verify RoHS or REACH conformity through product documentation or direct inquiry.

Production & Technical Capability Assessment

Evaluate supplier capacity based on operational indicators:

- On-time delivery rate exceeding 95%

- Response time under 3 hours for technical queries

- Demonstrated capability in high-voltage (≥450V), high-capacitance (≥10,000µF), and screw-terminal configurations

Cross-reference product listings with specialization tags—such as "Aluminum Electrolytic Capacitors" or "High-Frequency High-Voltage Components"—to assess core competency alignment.

Procurement Risk Mitigation

Utilize platform-backed transaction safeguards where available. Analyze online revenue trends (e.g., US $240,000+ annual volume) as an indicator of market trust and order throughput. Require sample testing for critical parameters including ESR, leakage current, and temperature stability before scaling orders. Prefer suppliers offering customization options in size, voltage rating, terminal type, and labeling for application-specific designs.

What Are the Best Electrolytic Capacitor Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | MOQ Flexibility | Customization |

|---|---|---|---|---|---|---|---|---|

| Digikey Electronic Solutions (Hong Kong) Limited | Hong Kong, CN | Other Electronic Components (14.8M+) | US $40,000+ | 88% | 18% | ≤2h | 1 piece | No |

| Shenzhen Worthy Electronics corp | Shenzhen, CN | Other ICs (952) | US $40,000+ | 93% | 27% | ≤5h | 1 piece | No |

| Dongguan A Friend Industrial Co., Ltd. | Dongguan, CN | Other Capacitors (346) | US $240,000+ | 100% | 23% | ≤3h | 50–1,000 pieces | No |

| Shenzhen Dianxian Technology Co., Ltd. | Shenzhen, CN | Multiple listings | US $510,000+ | 100% | 43% | ≤1h | 1 piece | Yes |

| Liaoning Icekey Refrigeration Co., Ltd. | Liaoning, CN | CBB60, CD136 Series (100+) | US $220,000+ | 93% | 21% | ≤2h | 100–300 pieces | Yes |

Performance Analysis

Shenzhen Dianxian Technology stands out with a 100% on-time delivery rate, sub-hour response time, and active customization support—making it ideal for agile development and low-volume prototyping. Its pricing model ($0.006–$0.20/unit) reflects competitive scalability for standard axial and radial electrolytic types. Dongguan A Friend Industrial demonstrates strong reliability (100% delivery) and specializes in high-capacitance screw-terminal units, though higher MOQs suggest suitability for industrial OEMs rather than R&D buyers. Liaoning Icekey, despite its refrigeration-focused branding, shows niche expertise in high-voltage photo-flash and motor-start capacitors, with customization capabilities aligned with legacy system replacements. Newer entrants like Shenzhen Worthy offer broad electronic component portfolios but lack capacitor-specific specialization, indicated by lower listing counts in dedicated categories.

FAQs

How to verify electrolytic capacitor supplier reliability?

Assess performance through documented on-time delivery rates (target ≥93%), reorder frequency (indicative of customer satisfaction), and response efficiency. Request test reports for capacitance, dissipation factor, and endurance under rated ripple current. Where possible, conduct factory audits via video tour to confirm production line automation and quality control checkpoints.

What is the typical sampling timeline for electrolytic capacitors?

Standard samples are typically shipped within 5–10 days after confirmation. Custom variants involving non-standard dimensions or voltage ratings may require 15–25 days for tooling adjustments and batch validation. Air shipping adds 3–7 days for international delivery.

Do suppliers support small-batch or prototype orders?

Yes, multiple suppliers—including Shenzhen Dianxian and Digikey Electronic Solutions—offer MOQs as low as one piece, facilitating design verification and bench testing. However, unit prices at low volumes may be 20–50% higher than bulk quotations.

Can electrolytic capacitors be customized for specific applications?

Suppliers like Shenzhen Dianxian and Liaoning Icekey explicitly list customization options for size, material, logo, and packaging. Engineering modifications such as extended temperature range, low-ESR formulations, or snap-in terminals should be discussed during technical onboarding, supported by detailed specification sheets.

What are common lead times and payment terms?

Lead times average 10–21 days post-payment confirmation, depending on order scale and customization. Payment methods vary; while T/T is standard, use of trade assurance platforms is recommended for first-time transactions to secure delivery guarantees and dispute resolution pathways.