Variable Capacitor Digikey

About variable capacitor digikey

Where to Find Variable Capacitor Suppliers?

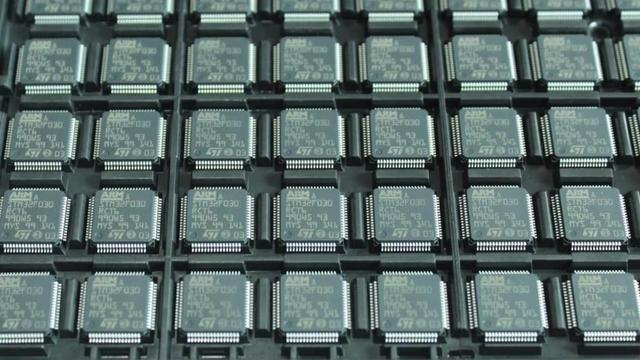

China serves as a dominant hub for variable capacitor manufacturing, with key production clusters concentrated in Guangdong, Zhejiang, and Ningbo regions. These areas host vertically integrated electronics supply chains, enabling rapid prototyping and scalable production of ceramic, vacuum, and film-based variable capacitors. Shenzhen and Dongguan specialize in high-frequency RF components used in communication systems, while Cixi and Ningbo focus on industrial-grade vacuum and ceramic variants for power transmission and broadcast equipment.

The regional ecosystems support tight integration between material sourcing, precision machining, and final assembly—reducing lead times by 20–30% compared to non-specialized manufacturers. Suppliers leverage proximity to ceramic dielectric producers and metal plating facilities to maintain consistent quality control. Average monthly output across verified suppliers ranges from 50,000 to over 500,000 units, depending on complexity and voltage ratings. Buyers benefit from flexible MOQs (as low as 1 piece) and access to niche products such as high-voltage tuning capacitors rated up to 28 kV.

How to Choose Variable Capacitor Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Product Range

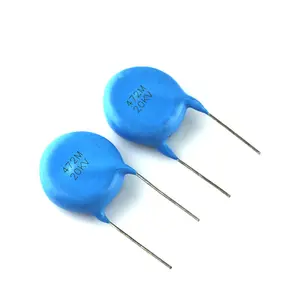

Confirm alignment with international standards including RoHS, REACH, and IEC 60384 for fixed and variable capacitors. For high-voltage applications, verify dielectric strength testing documentation and insulation resistance metrics. Evaluate whether suppliers offer critical variants: air-gap adjustable types, vacuum-sealed models for RF amplifiers, or trimmer capacitors for PCB-level tuning.

Production and Quality Assurance Infrastructure

Assess the following capabilities during due diligence:

- In-house ceramic processing or vacuum sealing lines for core component fabrication

- Environmental testing chambers for thermal cycling and humidity resistance validation

- Dedicated QA teams conducting 100% visual inspection and spot electrical testing

Cross-reference online revenue indicators and reorder rates; suppliers with >10% reorder activity typically maintain tighter process controls.

Procurement Flexibility and Transaction Security

Prioritize suppliers offering sample orders at minimal cost (some provide units under $0.10 for evaluation). Confirm MOQ scalability—from single-unit purchases to bulk lots exceeding 10,000 pieces. Use secure payment mechanisms such as trade assurance programs to mitigate risk. Response time is a strong proxy for service reliability, with top-tier suppliers replying within ≤2 hours.

What Are the Best Variable Capacitor Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Cixi Anxon Electronic Co., Ltd. | Ceramic, Aluminum Electrolytic, Other Capacitors | $20–400 | 1 piece | 100% | ≤10h | <15% | $8,000+ |

| Ningbo Setec Electron Co., Ltd. | Oscillators, Relays, Ceramic Capacitors | $1–60 | 1 piece | 100% | ≤4h | 33% | $10,000+ |

| Shenzhen Bixinda Technology Co., Ltd. | Adjustable Ceramic, DIP Capacitors | $0.10–0.50 | 10 pieces | 100% | ≤2h | <15% | $10,000+ |

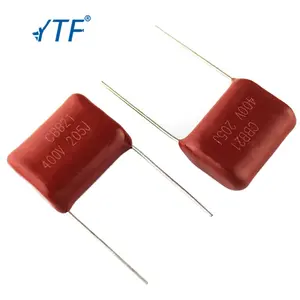

| Shenzhen Quanyuantong Electronics Co., Ltd. | Film, High-Voltage Components | $0.01–0.03 | 1 piece | 100% | ≤6h | <15% | $270,000+ |

| Dongguan City Gonghe Electronics Co., Ltd. | Film, Gang Tuning, Super Capacitors | $0.10–5.00 | 50–100 pieces | 100% | ≤7h | <15% | $3,000+ |

Performance Analysis

Shenzhen Quanyuantong stands out for cost efficiency and scale, offering sub-cent pricing on film-based variable capacitors with robust export volume. Ningbo Setec distinguishes itself with a 33% reorder rate—indicating strong customer retention—supported by fast response times and mid-range pricing. Shenzhen Bixinda provides optimal value for SMD and PCB-integrated trimmer capacitors, with MOQs starting at 10 units and prices below $0.50. Dongguan Gonghe specializes in legacy AM/FM tuning assemblies, catering to repair and restoration markets. While most suppliers report 100% on-time delivery, those with faster response times (≤4h) demonstrate higher operational responsiveness, critical for urgent procurement cycles.

FAQs

How to verify variable capacitor supplier reliability?

Validate compliance through available test reports for capacitance stability, temperature coefficient, and dielectric withstand voltage. Request product datasheets and cross-check material specifications (e.g., NPO ceramics, vacuum encapsulation). Analyze transaction history, focusing on consistent delivery performance and dispute resolution records.

What is the typical sampling timeline?

Standard samples are shipped within 3–7 days for in-stock items. Custom configurations involving high-voltage insulation or specific mounting interfaces require 10–15 days for fabrication and testing. Air freight adds 5–8 days for international delivery.

Can suppliers customize variable capacitors?

Yes, many suppliers support customization of capacitance range, shaft diameter, mounting style, and dielectric medium. Shenzhen Quanyuantong and Cixi Anxon explicitly list color, size, and lifetime adjustments as available options. Technical drawings or reference units improve accuracy in replication.

Do suppliers offer low-MOQ trials?

Most suppliers listed allow initial orders of 1–10 pieces, particularly for evaluation purposes. Units priced under $1 often have no minimum beyond a single piece, facilitating design verification before volume commitment.

Are high-voltage variable capacitors available?

Yes, several suppliers produce models rated up to 28 kV, primarily for RF transmitter and industrial heating applications. CKTB-series vacuum capacitors from Cixi Anxon and Ningbo Setec support these voltage levels with documented insulation integrity. Buyers should request partial discharge test results for safety-critical deployments.