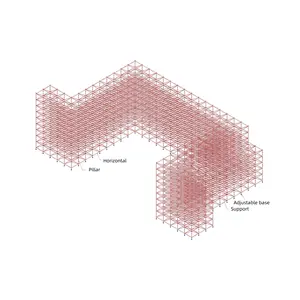

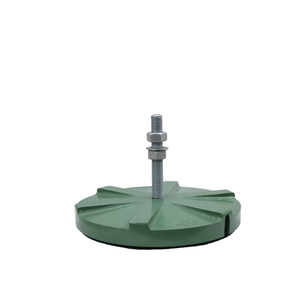

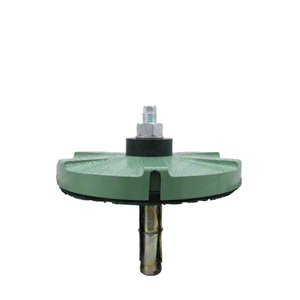

Dmls Support Structure

CN

CN

CN

CN

About dmls support structure

Where to Find DMLS Support Structure Suppliers?

China's industrial manufacturing base offers a concentrated network of suppliers specializing in Direct Metal Laser Sintering (DMLS) support structures, with key production hubs in Jiangsu, Shandong, Fujian, and Guangdong provinces. These regions host vertically integrated facilities combining advanced additive manufacturing capabilities with traditional metal fabrication, enabling precise lattice design, topology optimization, and rapid prototyping for complex structural components.

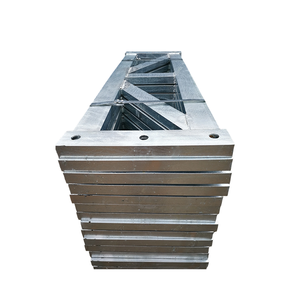

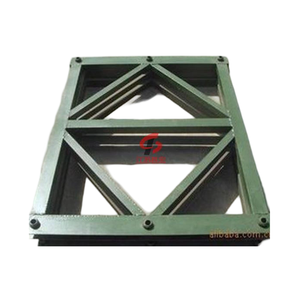

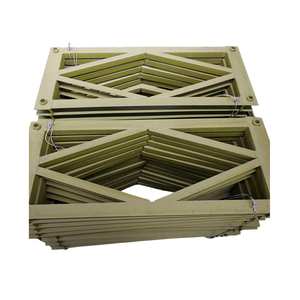

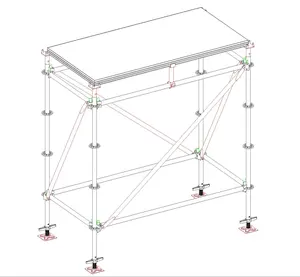

The ecosystem benefits from localized access to high-grade stainless steel, titanium, and aluminum powders, reducing material lead times by 20–30% compared to offshore alternatives. Suppliers in these clusters typically operate multi-axis laser systems and post-processing equipment—including stress-relief ovens and CNC finishing lines—supporting batch production of load-bearing brackets, trusses, and modular frames. Economies of scale are further enhanced through co-location with machining centers and quality inspection labs, allowing lead times as short as 15–25 days for custom DMLS parts.

How to Choose DMLS Support Structure Suppliers?

Selecting qualified partners requires rigorous evaluation across technical, operational, and transactional criteria:

Technical Capabilities Verification

Confirm the supplier’s proficiency in DMLS-specific design principles, including overhang management, thermal distortion compensation, and support structure minimization. Request evidence of STL file optimization workflows and experience with simulation tools (e.g., ANSYS or Materialise Magics). For load-critical applications, verify post-processing protocols such as hot isostatic pressing (HIP) and surface roughness treatment.

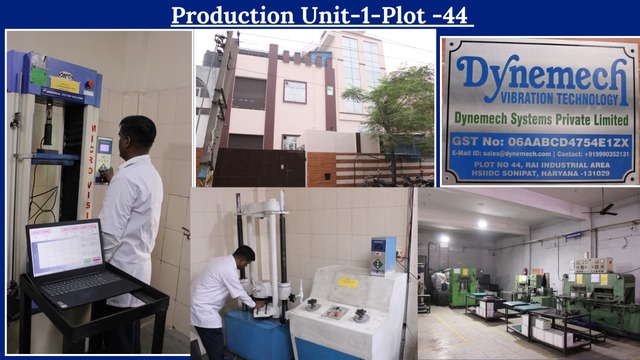

Production Infrastructure Assessment

Evaluate core manufacturing assets:

- In-house DMLS machines (EOS M290, SLM 280, or equivalent)

- Certified cleanroom environments for powder handling (ISO Class 6 or better)

- Integrated CNC, grinding, and metrology stations for final dimensioning

Cross-reference facility size with order volume requirements—suppliers with ≥5,000m² operations demonstrate scalability for medium-to-high-volume contracts.

Quality & Compliance Validation

Prioritize suppliers holding ISO 9001 certification and capable of providing full traceability documentation (material certificates, build logs, inspection reports). For aerospace or medical applications, AS9100 or ISO 13485 compliance is essential. Conduct third-party dimensional inspections using CMM or CT scanning, especially for internal lattice geometries.

What Are the Best DMLS Support Structure Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Jiangsu Shenghong Steel Structure Co., Ltd. | Jiangsu, CN | Steel Structures | $100–200 | 1 piece | 100% | ≤1h | - | - |

| Yimei Machinery Equipment Manufacturing Co., Ltd. | Shandong, CN | Other Mining Machines, Construction Machinery | $100–300 | 1–10 sets | 100% | ≤3h | <15% | US $10,000+ |

| Xiamen Ruiji Machinery Co., Ltd. | Fujian, CN | Machining Services, Sheet Metal Fabrication | $20–120 | 1 piece | 100% | ≤1h | <15% | US $2,000+ |

| Shandong Lubao Metal Group Co., Ltd. | Shandong, CN | Custom Steel Structures | $30–120 | 1,000 m² | 100% | ≤5h | 66% | US $370,000+ |

| Guangzhou Yunshang Zhizao Technology Co., Ltd. | Guangdong, CN | Tensile Structures, Membrane Architecture | $39–69 | 50–100 m² | 100% | ≤2h | <15% | US $4,000+ |

Performance Analysis

Xiamen Ruiji stands out for low-volume, high-precision DMLS bracket production, offering competitive pricing from $20/unit and immediate responsiveness (≤1h), ideal for prototyping and R&D sourcing. Jiangsu Shenghong provides scalable solutions for standardized bridge and frame supports, backed by consistent delivery performance. Shandong Lubao demonstrates strong customer retention (66% reorder rate) and large-scale fabrication capacity, suitable for industrial warehouse and modular building projects requiring hybrid DMLS-conventional steel integration. Guangzhou Yunshang specializes in architectural tensile systems where DMLS supports enable lightweight, freeform designs. Buyers should prioritize suppliers with documented DMLS process control and material testing when structural integrity is mission-critical.

FAQs

How to verify DMLS support structure quality?

Request build parameter records, porosity reports (target <0.5%), and mechanical test data (tensile strength, yield point). Validate surface finish consistency and dimensional accuracy via first-article inspection. For serial production, implement AQL 1.0 sampling plans during shipment audits.

What is the typical lead time for DMLS support components?

Standard orders require 15–25 days, including design validation, printing, support removal, heat treatment, and finishing. Complex geometries or large batches may extend timelines to 35 days. Expedited services (7–10 days) are available from select suppliers at a premium.

Can suppliers customize DMLS support structures?

Yes, most suppliers offer full customization of geometry, material (316L, Ti6Al4V, AlSi10Mg), surface treatment, and load specifications. Provide STEP or STL files with tolerance callouts and loading conditions for optimal redesign recommendations.

What are common MOQs for DMLS parts?

Minimum order quantities range from 1 piece for prototypes to 100+ units for serialized production. Some suppliers quote per square meter (e.g., for panelized structures), particularly in architectural applications.

Do suppliers provide design-for-additive-manufacturing (DfAM) support?

Leading suppliers offer DfAM consultation to optimize part orientation, reduce support volume, and improve print success rates. Confirm availability of topology optimization, lattice generation, and finite element analysis (FEA) during pre-production planning.