Doosan Cobot Programming

About doosan cobot programming

Where to Find Doosan Cobot Programming Suppliers?

China serves as a central hub for industrial robotics integration and automation solutions, with key supplier clusters located in Guangdong, Jiangsu, and Shandong provinces. These regions host vertically integrated ecosystems combining robotic arm manufacturing, control system development, and programming service delivery. Guangdong—particularly Shenzhen—leads in smart manufacturing innovation, offering access to advanced R&D centers focused on collaborative robot (cobot) programming interfaces and AI-driven automation workflows.

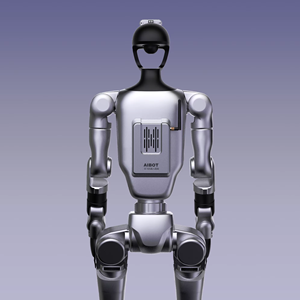

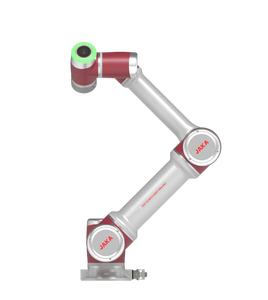

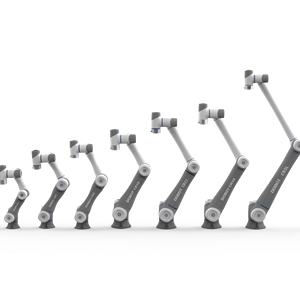

Suppliers in these zones benefit from proximity to component manufacturers, reducing lead times for custom integrations by 20–30%. The presence of specialized automation firms enables rapid deployment of Doosan cobot programming solutions, including offline programming environments, teach-pendant customization, and application-specific software tuning. Buyers gain access to modular programming frameworks compatible with H-Series and A-Series Doosan models, supporting payloads from 5kg to 20kg across diverse industrial applications such as welding, material handling, and CNC tending.

How to Choose Doosan Cobot Programming Suppliers?

Selecting qualified partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Expertise Verification

Confirm direct experience with Doosan Robotics SDKs and API integration. Suppliers should demonstrate proficiency in DRL (Doosan Robot Language) and support ROS/ROS2 compatibility for complex automation tasks. Request proof of completed programming projects, including simulation files or video demonstrations of implemented motion paths, safety logic, and I/O configurations.

Production & Integration Capability

Assess infrastructure readiness through the following criteria:

- Proven track record in deploying Doosan cobots with peripheral systems (e.g., linear rails, vision guidance, end-effectors)

- In-house software engineering team capable of custom HMI development and error-handling routines

- Availability of simulation tools like Doosan Studio or RoboDK for pre-deployment validation

Cross-reference project portfolios with response time metrics (target ≤4 hours) and on-time delivery performance (preferably ≥95%) to ensure reliability.

Transaction Security & After-Sales Support

Prioritize suppliers offering structured commissioning support, including remote debugging, on-site startup assistance, and operator training programs. Verify inclusion of source code documentation and version control practices. Utilize secure payment mechanisms such as escrow services, particularly when procuring high-value automation packages exceeding $15,000. Evaluate after-sales responsiveness via reorder rate indicators and customer feedback on troubleshooting efficiency.

What Are the Best Doosan Cobot Programming Suppliers?

| Company Name | Main Products | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Programming Focus |

|---|---|---|---|---|---|---|---|

| Jiangsu Greatway Electrical Co., Ltd. | Industrial Robots, Power Accessories | $13,000–35,000 | 100% | ≤4h | Not specified | Not specified | System integration for 20kg payload Doosan H-series arms |

| Shenzhen Era Automation Co., Ltd. | Collaborative Robots, AGVs | $390–13,900 | 100% | ≤2h | 50% | US $350,000+ | Easy-programming tool handles, DIY cobot kits compatible with Doosan architecture |

| Guangzhou Aobo Robot Technology Co., Ltd. | Service Robots, AI Programmable Units | $4,888–14,888 | Not specified | ≤4h | 100% | Not specified | AI-based programmable systems applicable to educational and light-industrial cobot use cases |

| Huiling-Tech Robotic Co., Ltd. | Manipulators, SCARA & Articulated Cobots | $3,000–7,600 | 100% | ≤5h | <15% | US $20+ | Industrial cobot arms with potential for reprogramming to emulate Doosan kinematics |

| Shenzhen Lianyizhi Technology Co., Ltd. | Welding Cobots, Laser Automation | $8,500–15,000 | 100% | ≤3h | <15% | US $40,000+ | Pre-programmed 6-axis welding cobots; supports integration with Doosan-compatible tooling and safety systems |

Performance Analysis

Jiangsu Greatway and Shenzhen Lianyizhi exhibit strong alignment with industrial-grade Doosan cobot deployments, particularly in high-payload and welding applications. Shenzhen Era Automation stands out for accessibility, offering low-cost programming tools and user-friendly interfaces ideal for SMEs adopting collaborative automation. Despite lower price points, several suppliers maintain 100% on-time delivery records, indicating robust production planning. However, reorder rates below 15% at Huiling-Tech and Lianyizhi suggest room for improvement in post-sale engagement or long-term client retention. Buyers seeking turnkey programming solutions should prioritize suppliers with documented experience in Doosan-specific software stacks and proven integration timelines under 30 days.

FAQs

How to verify Doosan cobot programming capability?

Request sample code snippets written in DRL, along with screenshots of the Doosan Control Panel configuration. Validate experience by reviewing case studies involving cycle time optimization, path accuracy calibration, or multi-cobot coordination. Confirm firmware update procedures and backup protocols for program recovery.

What is the typical lead time for programmed cobot systems?

Standard programming and testing cycles range from 15 to 25 days following hardware receipt. Complex applications involving vision integration or external axis synchronization may extend to 40 days. Add 7–14 days for international shipping depending on destination and customs clearance.

Can suppliers provide remote programming services?

Yes, most experienced vendors offer remote setup using secure VPN connections to configure Doosan controllers. This includes I/O mapping, safety circuit validation, and trajectory optimization without requiring on-site presence, reducing deployment costs significantly.

Is customization of programming interfaces available?

Reputable suppliers support UI localization, custom macro buttons, and simplified teaching modes for non-technical operators. Advanced options include touchscreen HMI development and integration with MES/SCADA platforms via Modbus TCP or OPC UA protocols.

What are common MOQ and pricing structures?

Most suppliers list minimum order quantities of 1 set, with prices varying based on payload, reach, and included software features. Entry-level programming packages start around $3,000, while fully integrated systems with tool changers and safety scanners exceed $30,000. Volume discounts apply for orders of five units or more.