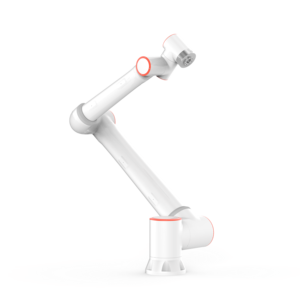

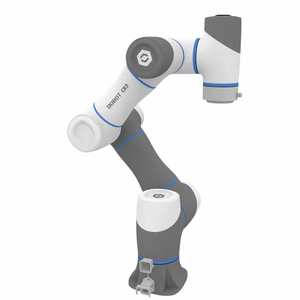

Doosan Collaborative Robot

About doosan collaborative robot

Where to Find Doosan Collaborative Robot Suppliers?

Global sourcing of Doosan collaborative robots is increasingly centralized among specialized industrial automation suppliers in China, particularly concentrated in Shanghai, Hebei, Jiangsu, and Guangdong provinces. These regions host integrated robotics ecosystems supported by mature supply chains for precision components, servo systems, and control modules—enabling rapid deployment and customization of cobot-integrated solutions. Shanghai and Jiangsu serve as hubs for high-payload, six-axis robotic arms with advanced safety certifications, while Hebei and Guangdong focus on cost-optimized models tailored for small-to-medium enterprises.

The regional clusters benefit from proximity to Tier-1 component manufacturers and R&D centers, reducing integration lead times by 20–35% compared to standalone importers. Suppliers in these zones typically operate within vertically aligned production networks that include CNC machining, welding, and final assembly under one ecosystem. This enables standardized quality control and faster turnaround for both standard and customized configurations. Buyers gain access to scalable production capacities, with average monthly outputs ranging from 50 to 200 units per supplier, depending on model complexity and payload requirements.

How to Choose Doosan Collaborative Robot Suppliers?

Procurement decisions should be guided by rigorous technical and operational assessments:

Technical Compliance & Safety Standards

Verify adherence to international safety protocols such as ISO/TS 15066 for collaborative operations and CE marking for European market compliance. Critical performance indicators include payload accuracy (±0.02 mm), repeatability (within ±0.05 mm), and built-in force-limiting technology. Demand documentation for tested operational parameters including reach (up to 1,700 mm), maximum speed (up to 2.2 m/s), and cycle life validation (typically rated for 20,000+ hours).

Production Capability Verification

Assess supplier infrastructure through the following benchmarks:

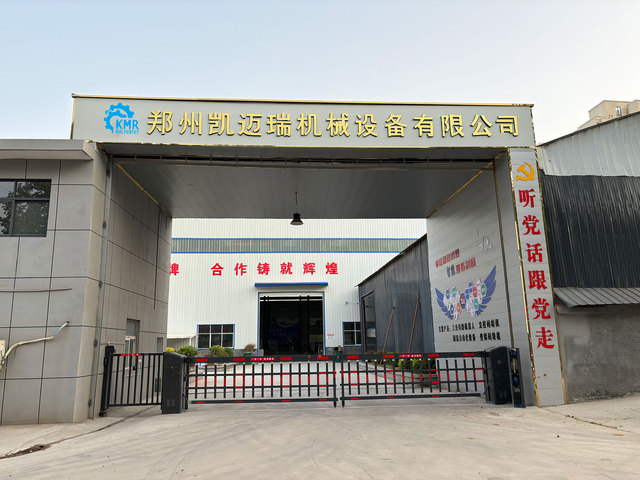

- Minimum factory area exceeding 2,000m² to support dedicated cobot testing and calibration lines

- In-house engineering teams capable of handling custom gripper integration, software tuning, and end-of-arm tooling (EOAT)

- On-site demonstration facilities or video verification of functional testing

Cross-reference delivery performance (target ≥90%) with response time metrics (ideally ≤8 hours) to gauge operational reliability.

Transaction Security & After-Sales Support

Prioritize suppliers offering third-party transaction protection and post-delivery technical support. Confirm availability of firmware updates, remote diagnostics, and spare parts inventory. Request evidence of export experience, especially for markets requiring regulatory alignment (e.g., FCC for North America, KC for South Korea). Onboarding documentation should include user manuals, electrical schematics, and risk assessment reports.

What Are the Best Doosan Collaborative Robot Suppliers?

| Company Name | Location | Product Range (Doosan Models) | Payload Range | Avg. Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Xiangjing (Shanghai) Mechanical and Electrical Tech Co., Ltd. | Shanghai, CN | E0509, A0912, H2017, H2515 | 5–25 kg | $15,500–$58,000 | 100% | ≤8h | 20% | Color, material, size, payload, logo, packaging, graphic, gripper |

| Hebei Paiyuan Intelligent Technology Co., Ltd. | Hebei, CN | CR7, HN-series equivalents | 6–53 kg | $6,220–$19,100 | 75% | ≤5h | 50% | Limited (primarily structural variants) |

| Jiangsu Greatway Electrical Co., Ltd. | Jiangsu, CN | A0912, H-series references | 9–12 kg | $18,000–$55,000 | 100% | ≤5h | No data | Integration-focused (grippers, controllers) |

| Beijing LJ Robot Technology Co., Ltd. | Beijing, CN | Generic cobot designs (non-specific Doosan models) | Not specified | $2,600–$3,800 | 50% | ≤1h | 100% | Minimal (commercial service robot focus) |

| Guangdong Borunte Robot Technology Co., Ltd. | Guangdong, CN | H2017, FR-series compatible | 3–20 kg | $999–$7,500 | 75% | ≤3h | 50% | Gripper, arm configuration, control interface |

Performance Analysis

Xiangjing (Shanghai) stands out with full 100% on-time delivery, a broad product range covering key Doosan models like the H2515 and A0912, and extensive customization capabilities across mechanical and aesthetic parameters. Its higher price positioning reflects premium build quality and technical flexibility. Hebei Paiyuan offers competitive pricing for mid-payload applications but lacks documented customization depth. Jiangsu Greatway demonstrates strong reliability (100% delivery) and targets integration-ready buyers seeking compatibility with existing automation cells. In contrast, lower-priced offerings from Beijing LJ and Guangdong Borunte suggest entry-level or repurposed robotic platforms, potentially unsuitable for industrial-grade Doosan replacements despite nominal payload alignment. Buyers prioritizing authenticity and long-term support should verify OEM partnerships and avoid anomalously low pricing indicative of imitation systems.

FAQs

How to verify Doosan collaborative robot supplier authenticity?

Cross-check product specifications against official Doosan Robotics datasheets, focusing on model nomenclature, serial traceability, and controller compatibility. Request proof of authorized distribution agreements or technical collaboration. Analyze listed products for consistency in torque ratings, joint angles, and safety certification marks.

What is the typical lead time for Doosan cobot orders?

Standard delivery ranges from 30 to 45 days after order confirmation. Custom configurations involving specialized end-effectors or communication protocols (e.g., PROFINET, EtherCAT) may extend timelines to 60 days. Air freight reduces shipping duration to 5–10 days but increases costs significantly for heavy units.

Are customization options available for Doosan collaborative robots?

Yes, leading suppliers offer configurable options including gripper types, paint finishes, cable routing, labeling, and software interface localization. High-end providers support API access for PLC integration and IoT connectivity. Confirm feasibility through technical consultation prior to order placement.

Do suppliers provide samples or trial units?

Sample availability varies. Some suppliers offer demo units for evaluation at full or partial cost recovery. Trials are more common for bulk contracts (≥5 units). Expect sample fees to cover 40–60% of unit price, often redeemable against future orders.

What are the minimum order quantities (MOQ) and payment terms?

Most suppliers list MOQ at 1 set, facilitating pilot deployments. Payment structures typically require 30–50% deposit with balance before shipment. Escrow services and trade assurance programs are recommended to mitigate financial risk, especially for first-time transactions.