Motoman Collaborative Robot

CN

CN

1/12

1/12

CN

CN

1/14

1/14

1/33

1/33

1/5

1/5

CN

CN

1/23

1/23

1/3

1/3

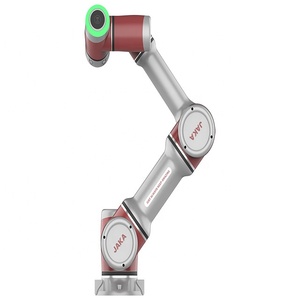

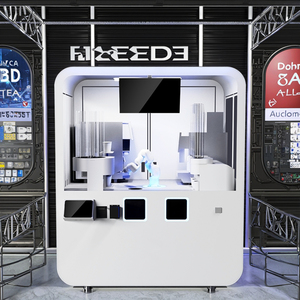

About motoman collaborative robot

Where to Find Motoman Collaborative Robot Suppliers?

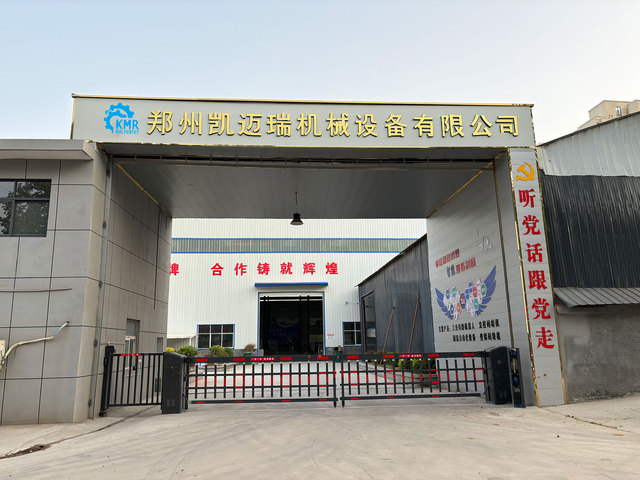

China has emerged as a central hub for sourcing industrial automation solutions, including Motoman collaborative robots (cobots), with key suppliers concentrated in Shandong, Anhui, and Guangdong provinces. These regions host integrated robotics ecosystems supported by mature supply chains for precision components, servo systems, and control units. Industrial clusters in Jinan and Qingdao specialize in robotic arm manufacturing, while Hefei-based firms focus on integration with CNC and welding systems, enabling modular automation setups.

Suppliers leverage vertically aligned production networks—spanning casting, machining, assembly, and testing—to reduce lead times and maintain cost efficiency. The proximity of component manufacturers allows for rapid prototyping and scalable production, with standard cobot units typically available within 30–45 days. Buyers benefit from localized access to technical talent, logistics infrastructure, and customization capabilities, particularly for payload-specific configurations and integration-ready solutions.

How to Choose Motoman Collaborative Robot Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Product Authenticity

Verify that suppliers provide genuine Yaskawa Motoman products or authorized reconfigurations. Request documentation such as product serial numbers, original equipment manufacturer (OEM) authorization, and compliance with IEC 61508 for functional safety. CE marking is essential for European market entry, while UL certification supports North American deployments.

Production and Integration Capabilities

Assess supplier infrastructure through the following benchmarks:

- Minimum facility size of 2,000m² indicating capacity for batch production

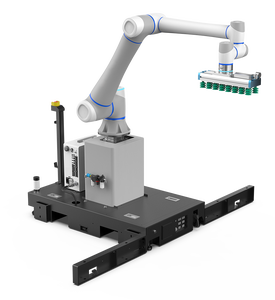

- In-house engineering teams capable of system integration (e.g., vision guidance, end-of-arm tooling)

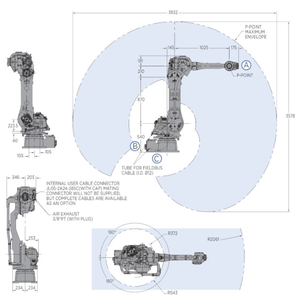

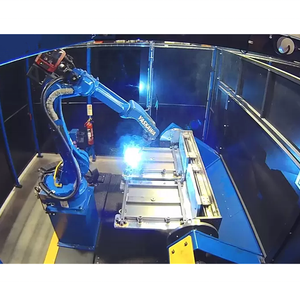

- Proven experience with 6-axis articulated robots and collaborative safety features (force-limited joints, speed monitoring)

- Cross-reference response time (target ≤4 hours) and on-time delivery rate (ideal ≥96%) as indicators of operational reliability

Transaction Security and After-Sales Support

Prioritize suppliers offering third-party transaction protection and post-delivery support, including remote diagnostics, spare parts availability, and programming assistance. Analyze reorder rates as a proxy for customer satisfaction—rates exceeding 50% suggest strong service performance. Conduct video audits to confirm inventory authenticity and test unit availability before purchase.

What Are the Best Motoman Collaborative Robot Suppliers?

| Company Name | Location | Verified Status | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Gongboshi Robot Technology Co., Ltd. | Shandong, CN | Multispecialty Supplier | US $20,000+ | 100% | ≤4h | <15% | Color, material, size, logo, weight, packaging, label, graphic |

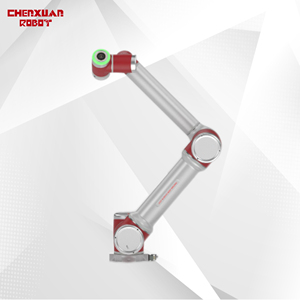

| Shandong Chenxuan Robot Technology Co., Ltd. | Shandong, CN | Custom Manufacturer | - | 100% | ≤2h | - | Color, material, size, logo, packaging, label, graphic |

| Jinan Lingyu International Trade Co., Ltd. | Shandong, CN | Multispecialty Supplier | US $40,000+ | 89% | ≤1h | 22% | Color, material, size, logo, packaging, label, graphic |

| Anhui Gongboshi Tech. Co., Ltd | Anhui, CN | Unverified | - | 100% | ≤18h | - | Limited public data |

| Anhui Jinhey Tech. Co., Ltd. | Anhui, CN | Unverified | US $170,000+ | 96% | ≤2h | 55% | Limited public data |

Performance Analysis

Gongboshi Robot Technology and Shandong Chenxuan stand out for guaranteed on-time delivery and responsive communication, making them suitable for time-sensitive procurement. Despite lower reorder rates, their verified status and customization breadth support standardized deployments. In contrast, Anhui Jinhey Tech. reports a high reorder rate (55%) and substantial online revenue, suggesting consistent buyer retention despite unverified status. Jinan Lingyu offers fast response times but exhibits below-industry-average on-time delivery (89%), indicating potential fulfillment risks. Unverified suppliers require additional due diligence, especially regarding product authenticity and after-sales accountability.

FAQs

How to verify Motoman collaborative robot supplier reliability?

Cross-check product specifications against official Yaskawa documentation. Request proof of certification (CE, ISO 9001), transaction history, and customer references. Use platform-backed trade assurance programs to mitigate financial risk during initial transactions.

What is the typical MOQ and pricing range?

Minimum order quantities vary from 1 piece to 1 dozen, depending on model and supplier. Pricing ranges from $4,578 for compact units to $46,000 for high-payload industrial models (e.g., GP50). Most suppliers accept single-set orders, facilitating pilot deployments.

Do suppliers offer customization options?

Yes, leading suppliers provide customization in color, branding (logo), packaging, material finishes, and labeling. Some support limited structural modifications, though major changes to kinematics or control systems may require direct OEM engagement.

What are the average lead times for delivery?

Standard delivery timelines range from 15 to 30 days after order confirmation, depending on customization level and shipping method. Air freight reduces transit time to 5–10 days internationally, while sea freight takes 25–40 days but lowers logistics costs for bulk orders.

Can suppliers integrate cobots with existing production lines?

Suppliers with articulated robot expertise often provide integration services, including mounting fixtures, PLC interfacing, and programming for pick-and-place, welding, or palletizing tasks. Confirm prior experience with similar applications before contracting.