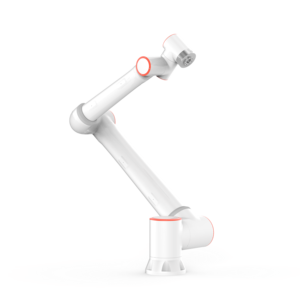

Omron Collaborative Robot

CN

CN

About omron collaborative robot

Where to Find OMRON Collaborative Robot Suppliers?

China's industrial automation sector has emerged as a global hub for collaborative robot (cobot) manufacturing, with key supplier clusters concentrated in Shanghai, Guangdong, and Jiangsu provinces. These regions host vertically integrated ecosystems combining precision engineering, robotic R&D centers, and advanced electronics production. Shanghai and Suzhou serve as innovation anchors, hosting over 40% of China’s cobot-focused technology firms, while Guangdong leverages its proximity to Shenzhen’s semiconductor supply chain to reduce component lead times by 25-30%.

The clustering enables rapid prototyping and scalable production through co-located CNC machining, servo motor assembly, and control system integration. Suppliers benefit from localized access to structural materials like aerospace-grade aluminum alloys and carbon fiber composites, reducing material procurement cycles to under 10 days. Buyers gain operational advantages including lead times of 20–35 days for standard configurations, 15–25% cost savings versus EU/North American manufacturers, and flexibility for both bulk deployments and application-specific customization.

How to Choose OMRON Collaborative Robot Suppliers?

Procurement decisions should be guided by rigorous evaluation criteria focused on technical integrity, production reliability, and transactional safeguards:

Technical Compliance & Integration

Confirm compatibility with OMRON’s TM series control architecture and validate adherence to ISO 10218-1 (industrial robots) and ISO/TS 15066 (collaborative applications). For international deployment, CE or UKCA certification is essential for regulatory compliance. Request documentation for safety-rated monitored stop, power-and-force limiting, and hand-guiding functionality testing.

Production Capability Verification

Assess core operational metrics:

- Minimum factory area exceeding 2,000m² to support dedicated assembly lines

- In-house engineering teams capable of customizing end-effectors, software interfaces, and motion programming

- On-site testing facilities for payload validation (3–14 kg range), repeatability checks (±0.05 mm), and cycle endurance trials

Cross-reference listed product specifications with verified delivery performance—target suppliers maintaining ≥95% on-time shipment rates.

Transaction & Quality Assurance

Utilize secure payment mechanisms such as escrow services contingent upon pre-shipment inspection reports. Prioritize suppliers offering sample units for functional evaluation, particularly for high-payload (≥6 kg) or extended-reach (≥1,300 mm) models. Validate software compatibility with common PLCs and HMI systems used in automated workcells.

What Are the Leading OMRON Collaborative Robot Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Gongboshi Robot Technology Co., Ltd. | China | Multiple cobot models (5) | US $20,000+ | 100% | ≤4h | <15% | Color, material, size, logo, packaging, label, graphic |

| Robotphoenix Intelligent Technology Co.,Ltd | China | Manipulator (588), AGV (209) | US $30,000+ | 100% | ≤2h | 100% | Limited (not specified) |

| Xiangjing (Shanghai) Mechanical And Electrical Tech Co., Ltd. | Shanghai, CN | Cobots, SCARA, robotic arms (5) | US $50,000+ | 100% | ≤7h | 20% | Programmable parameters, grippers, control panels, explosion-proof covers, reach, payload, software |

| Suzhou JJD Electronic Technology Co., Ltd. | Jiangsu, CN | Articulated Robots (103), Cobots (65) | US $130,000+ | 100% | ≤5h | 45% | Limited (not specified) |

| Guangdong Borunte Robot Technology Co., Ltd. | Guangdong, CN | Articulated Robots (157), Cobots (32) | US $20,000+ | 66% | ≤3h | 100% | Limited (not specified) |

Performance Analysis

Suppliers like Suzhou JJD demonstrate strong production scale with over 65 cobot listings and the highest reported online revenue (US $130,000+), indicating consistent order volume. Xiangjing (Shanghai) offers the broadest customization scope, supporting modifications across mechanical, electrical, and software domains—critical for integrating cobots into existing OMRON-based automation cells. Robotphoenix stands out for customer retention with a 100% reorder rate and sub-2-hour response time, suggesting robust after-sales support. While most suppliers maintain perfect on-time delivery records, Guangdong Borunte’s 66% fulfillment rate presents a notable risk factor despite competitive pricing. Buyers seeking deep integration capabilities should prioritize suppliers with documented experience in OMRON TM-series replication or interoperability.

FAQs

How to verify OMRON collaborative robot supplier authenticity?

Request proof of authorized distribution or technical licensing if claiming OEM/OEM partnerships. Validate product conformity through independent lab testing of torque output, path accuracy, and emergency stop response time. Analyze customer references for installations involving similar payload and duty cycle requirements.

What is the typical lead time for cobot orders?

Standard units ship within 20–30 days after order confirmation. Customized configurations requiring modified arms, control cabinets, or software integrations may require 35–50 days. Air freight adds 5–7 days globally; sea freight ranges from 25–40 days depending on destination port.

Do suppliers support global shipping and customs clearance?

Yes, established exporters manage international logistics under FOB, CIF, or DDP terms. Confirm inclusion of export documentation (commercial invoice, packing list, bill of lading) and compliance with IEC 61508 for functional safety where applicable. Pre-shipment inspections are recommended for orders exceeding five units.

Are samples available for functional testing?

Sample availability varies. Some suppliers offer test units at reduced cost (30–50% of MSRP) refundable against future orders. Expect lead times of 15–25 days for sample production and configuration. High-payload models may incur non-refundable setup fees due to specialized calibration needs.

What customization options are commonly offered?

Leading suppliers provide configurable parameters including arm length (700–1,400 mm), payload capacity (3–14 kg), base mounting (floor, wall, ceiling), IP rating upgrades, and integration-ready communication protocols (EtherCAT, Modbus TCP). Software-level customization includes teach pendant language localization, API access, and HMI skinning for operator interface alignment.