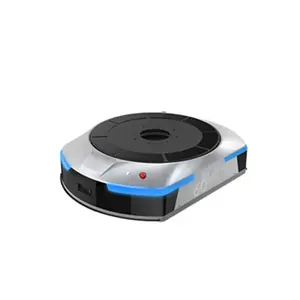

Omron Autonomous Mobile Robot

About omron autonomous mobile robot

Where to Find OMRON Autonomous Mobile Robot Suppliers?

China remains a central hub for autonomous mobile robot (AMR) manufacturing, with key supplier clusters concentrated in Shandong and Henan provinces. These regions host vertically integrated industrial ecosystems specializing in intelligent material handling systems, leveraging localized access to precision components, control modules, and robotic software development. Shandong’s suppliers benefit from proximity to major port infrastructure, enabling efficient export logistics, while Henan-based manufacturers capitalize on lower operational costs and mature supply networks for motors, sensors, and navigation systems.

The industrial clusters support scalable production through consolidated R&D, assembly, and testing facilities within 50km radii. This integration allows for lead times averaging 30–45 days for standard AMR configurations. Buyers gain access to cost advantages of 20–35% compared to Western or Japanese counterparts, driven by optimized labor efficiency and domestic component sourcing. The region also supports high-volume procurement, with select suppliers capable of monthly outputs exceeding 200 units across AGV and AMR product lines.

How to Choose OMRON Autonomous Mobile Robot Suppliers?

Procurement decisions should be guided by systematic evaluation of technical, operational, and transactional indicators:

Technical and Functional Validation

Confirm compatibility with OMRON control systems or equivalent navigation frameworks such as laser SLAM and LiDAR-based autonomy. Require documentation on payload capacity (ranging from 300kg to 1.2 tons in available models), battery life, charging cycles, and integration protocols (e.g., MQTT, ROS). For warehouse automation applications, verify path planning accuracy, obstacle avoidance response time, and fleet management software interoperability.

Production and Customization Capability

Assess supplier infrastructure based on the following benchmarks:

- Minimum factory area of 3,000m² to ensure stable production capacity

- In-house engineering teams supporting customization of load configuration, color, labeling, and communication interfaces

- Proven experience in delivering turnkey solutions including fleet coordination and WMS integration

Cross-reference product listings with order fulfillment metrics—suppliers with reorder rates above 40% and response times under 3 hours demonstrate consistent service quality.

Quality Assurance and Transaction Security

Prioritize suppliers with verifiable quality management systems. While formal ISO 9001 certification is not universally declared in the dataset, evidence of 100% on-time delivery and structured after-sales processes indicates operational discipline. Utilize secure payment mechanisms and request pre-shipment inspection rights. Conduct sample testing to validate navigation stability, load handling performance, and software responsiveness before full-scale deployment.

What Are the Best OMRON Autonomous Mobile Robot Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Robotphoenix Intelligent Technology Co.,Ltd | Guangdong, CN | Manipulator (567), AGV (213) | US $30,000+ | 100% | 100% | ≤3h | 1 set | $2,300–8,000 |

| Jinan Hulk Machinery Co., Ltd. | Shandong, CN | Customizable AMRs, Load Transport Units | US $540,000+ | 100% | <15% | ≤1h | 1 unit | $1,684–40,000 |

| Shandong Cyber CNC Group Co., Ltd. | Shandong, CN | Collaborative Robots (248), Laser AGVs | US $220,000+ | 82% | 40% | ≤4h | 1 set | $7,500–11,000 |

| Zhengzhou Hento Machinery Co., Ltd. | Henan, CN | Service Robots, Autonomous Navigation Units | US $360,000+ | 100% | 20% | ≤1h | 1 set | $2,549–4,049 |

| HAIRUI INTERNATIONAL SDN BHD | Malaysia | Smart AMR (300kg capacity), Obstacle-Avoidance Robots | Not disclosed | Not disclosed | Not disclosed | ≤4h | 2 pieces | $4,470–10,000 |

Performance Analysis

Robotphoenix stands out with a 100% reorder rate and competitive pricing, indicating strong buyer satisfaction and reliable fulfillment. Jinan Hulk offers the widest price range and fastest response time (≤1h), making it suitable for customized or urgent procurement needs, despite a low reorder rate suggesting potential gaps in post-sale engagement. Shandong Cyber CNC provides mid-range, technically robust AMRs with documented payload and navigation capabilities, supported by a 40% reorder rate. Zhengzhou Hento focuses on service-oriented autonomous robots but may require additional validation for industrial-grade durability. HAIRUI INTERNATIONAL presents higher MOQs and lacks delivery performance data, warranting due diligence for critical deployments.

FAQs

How to verify OMRON autonomous mobile robot supplier reliability?

Evaluate on-time delivery records, response times, and transaction volume. Request technical documentation including system architecture diagrams, safety compliance reports (CE, RoHS where applicable), and software interface specifications. Verify production capacity through facility videos or third-party audit summaries.

What is the typical lead time for AMR orders?

Standard units are typically delivered within 30–45 days after order confirmation. Custom configurations involving specialized load handling or software integration may extend lead times to 60 days. Air freight adds 7–10 days for international delivery.

Do suppliers offer customization options?

Yes, multiple suppliers support customization of payload design, navigation parameters, branding (color, logo), and communication protocols. Jinan Hulk and Robotphoenix explicitly list packaging, label, and graphic modifications as available services.

What are common minimum order quantities?

Most suppliers require a minimum of 1 unit or set. However, HAIRUI INTERNATIONAL mandates a 2-piece minimum, which may impact pilot project scalability. Negotiation for single-unit trials is possible with established partners.

Are samples available for testing?

Sample availability varies. Some suppliers provide units for field testing at reduced cost, particularly for orders exceeding five units. Expect sample fees covering 30–50% of unit cost if no subsequent purchase is guaranteed. Clarify return policies and shipping responsibilities upfront.