Edc Multi Tool Producer

CN

CN

About edc multi tool producer

Where to Find EDC Multi Tool Producers?

China remains the global epicenter for EDC (Everyday Carry) multi tool manufacturing, with key production hubs concentrated in Guangdong and Shaanxi provinces. These regions host vertically integrated supply chains specializing in precision metalworking, CNC machining, and small-batch customization—critical for high-tolerance tools used in tactical, outdoor, and utility applications. Baoji City in Shaanxi has emerged as a titanium processing cluster, leveraging local raw material access and advanced CNC capabilities to produce lightweight, corrosion-resistant EDC tools. Meanwhile, Foshan and Yangjiang in Guangdong offer mature ecosystems for stainless steel fabrication, benefiting from decades of cutlery and hardware export experience.

The industrial clusters enable cost-efficient scaling through shared infrastructure in machining, surface treatment, and logistics. Suppliers typically operate in-house production lines covering blanking, CNC milling, heat treatment, polishing, and laser engraving, reducing dependency on external vendors. This integration allows lead times as low as 15–20 days for standard orders and supports flexible MOQs ranging from 2 to 500 units. Buyers benefit from localized component sourcing, which reduces material costs by 15–25% compared to Western or Southeast Asian manufacturers, particularly for titanium and hardened stainless steel variants.

How to Choose EDC Multi Tool Suppliers?

Selecting reliable producers requires systematic evaluation across technical, operational, and transactional dimensions:

Production & Customization Capability

Verify suppliers possess in-house CNC machining and finishing capabilities, essential for maintaining dimensional accuracy and material integrity. Preferred partners offer customization options including laser engraving, anodizing, folding mechanisms, and material selection (e.g., Grade 5 titanium, 440C stainless steel). Confirm support for design personalization such as logo imprinting, packaging labels, and unique tool configurations (e.g., pry bars, bottle openers, screwdrivers).

Quality Control & Compliance

While formal certifications like ISO 9001 are not universally listed, performance indicators such as on-time delivery rates (>95%) and reorder rates (>17%) serve as proxies for reliability. Prioritize suppliers with documented quality checks at multiple stages—raw material inspection, in-process testing, and final assembly verification. Material traceability and hardness testing (e.g., Rockwell C scale for blades) should be available upon request.

Transaction & Risk Mitigation

Leverage secure payment methods with escrow protection, especially for first-time engagements. Analyze supplier responsiveness (target ≤2 hours) and historical order fulfillment data. Request physical or digital samples before bulk ordering to evaluate finish quality, ergonomics, and functional durability. For customized designs, insist on pre-production prototypes and photo confirmation of tool details, packaging, and branding elements.

What Are the Best EDC Multi Tool Suppliers?

| Company Name | Main Materials | Production Focus | Customization Options | MOQ Range | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Baoji City Huatianyi New Material Technology Co., Ltd. | Titanium, Stainless Steel | Titanium EDC Tools, CNC Machined Components | Limited (material, size, logo) | 50–100 pcs | 43% | ≤4h | US $30,000+ | 20% |

| Foshan Grace Metal Co., Ltd. | Stainless Steel | Mass-Produced Multi-tools, Survival Gadgets | Moderate (logo, packaging) | 50–500 sets | 94% | ≤2h | US $70,000+ | 17% |

| Yangjiang Shengjia Trading Co., Ltd. | Stainless Steel | OEM/ODM Small Tools, Compact Designs | High (color, size, logo, packaging) | 2–1200 pcs | 100% | ≤2h | US $40,000+ | <15% |

| Yangjiang Hongrui Industry And Trade Co., Ltd. | Stainless Steel, Titanium, Plastics | Diverse EDC Tool Configurations, Folding Mechanisms | Extensive (engraving, materials, folding, packaging) | 1–120 pcs | 96% | ≤2h | US $310,000+ | 19% |

| World Backyard (Shenzhen) Network Technology Co., Ltd. | Stainless Steel, Damascus Steel, Ti-Coated | High-Customization Multi-tools, Tactical Pliers | Very High (full design, materials, finishes, packaging) | 10–500 pcs | 95% | ≤2h | US $550,000+ | 20% |

Performance Analysis

Baoji Huatianyi specializes in titanium-based EDC tools but shows lower on-time delivery performance (43%), suggesting potential logistical constraints despite strong material expertise. In contrast, Yangjiang Shengjia achieves perfect on-time fulfillment (100%) with highly flexible MOQs starting at 2 pieces, making it ideal for prototyping or niche product testing. Foshan Grace Metal offers competitive pricing (from $0.95/unit) for high-volume buyers, though customization depth is limited. Yangjiang Hongrui and World Backyard stand out for extensive personalization—supporting laser cutting, kydex sheaths, and multi-material assemblies—backed by robust online revenues exceeding US $300,000 annually. These suppliers cater well to branded or specialty markets requiring differentiated designs.

FAQs

What materials are commonly used in EDC multi tools?

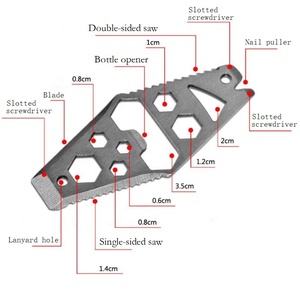

Stainless steel (especially 440C and 304 grades) is most common due to its balance of hardness, corrosion resistance, and cost. Titanium (Grade 5) is preferred for premium lightweight tools. Some suppliers also offer damascus steel, coated blades (TiN/TiCN), and composite plastics for handles.

What is the typical MOQ for custom EDC multi tools?

MOQs vary widely: basic models start at 2–10 pieces for sample runs, while fully customized designs (with logos, unique tool layouts, or special finishes) typically require 100–500 units. High-complexity builds may require higher volumes to justify tooling setup.

How long does production and shipping take?

Standard orders take 15–25 days for manufacturing, with an additional 5–10 days for air freight to international destinations. Custom tooling or large batches may extend lead times to 35 days. Express production (rush orders) is available from select suppliers within 7–10 days at a premium.

Can suppliers provide product certification or testing reports?

While formal compliance certificates (e.g., CE, RoHS) are not always declared, reputable suppliers can provide material test reports, hardness verification, and functional performance data upon request. Third-party inspection services can be arranged pre-shipment for critical orders.

Are free samples available?

Most suppliers offer paid samples (priced at 1–2x unit cost) to cover production and shipping. Sample fees may be credited toward future bulk orders. Fully free samples are rare unless part of an established business relationship or promotional campaign.