Engineered Product Prototyping

Top sponsor listing

Top sponsor listing

1/58

1/58

1/8

1/8

1/29

1/29

1/20

1/20

1/30

1/30

1/10

1/10

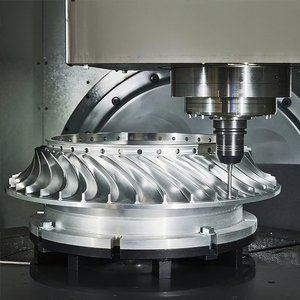

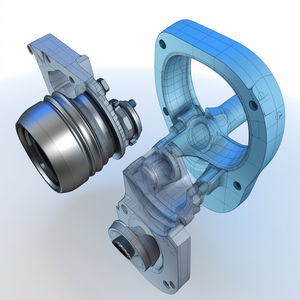

About engineered product prototyping

Where to Find Engineered Product Prototyping Suppliers?

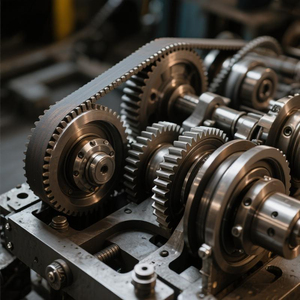

China remains a central hub for engineered product prototyping, with key manufacturing clusters in Shenzhen and Shanghai offering advanced capabilities in rapid prototyping, CNC machining, and injection molding. Shenzhen’s electronics and hardware ecosystem supports high-precision engineering services, particularly for consumer electronics, medical devices, and industrial equipment. The city’s proximity to component suppliers and logistics networks enables agile development cycles and fast turnaround times.

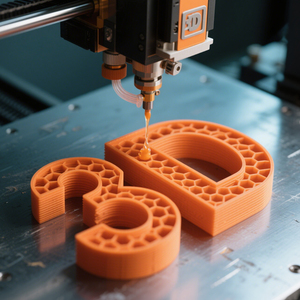

Shanghai’s prototyping sector emphasizes integrated mold design and low-volume production, leveraging localized tooling and material supply chains to reduce lead times by 20–35% compared to Western alternatives. These regions host vertically integrated facilities capable of handling full project lifecycles—from CAD modeling and 3D printing to functional testing and small-batch manufacturing. Buyers benefit from access to skilled technical teams, competitive pricing structures, and scalable production models tailored to both startups and established OEMs.

How to Choose Engineered Product Prototyping Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional criteria:

Technical Capabilities & Compliance

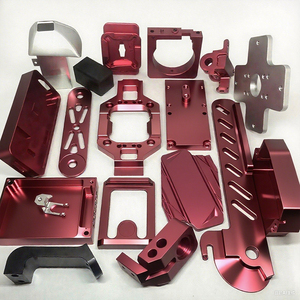

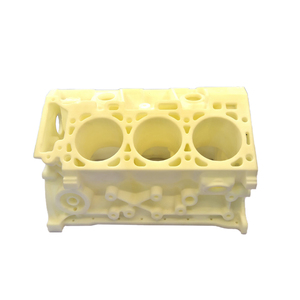

Confirm that suppliers support required prototyping methods such as CNC machining, SLA/SLS 3D printing, vacuum casting, or sheet metal fabrication. While formal certifications like ISO 9001 are not explicitly listed in available data, prioritize partners demonstrating structured quality management through documented processes. For regulated industries (e.g., medical, aerospace), verify compliance with RoHS, REACH, or industry-specific standards during due diligence.

Production Infrastructure Assessment

Evaluate core competencies based on service offerings and operational scale:

- Proven expertise in machining services, mold development, and other fabrication techniques

- Support for multi-material prototyping (ABS, nylon, PMMA, aluminum, stainless steel)

- Demonstrated customization capacity including color, labeling, packaging, and surface finishing

Cross-reference response time metrics (target ≤4 hours) and on-time delivery performance (preferably ≥98%) as indicators of operational reliability.

Procurement Safeguards

Utilize secure payment mechanisms where available, especially for initial engagements. Request sample prototypes to validate dimensional accuracy, material integrity, and finish quality before scaling orders. Analyze reorder rates—ranging from 20% to 46% among identified suppliers—as a proxy for customer satisfaction and service consistency.

What Are the Best Engineered Product Prototyping Suppliers?

| Company Name | Location | Verified Type | Main Services | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Strongd Model Technology Co., Ltd. | Shenzhen, CN | Custom Manufacturer | Machining, Moulds, Fabrication | 98% | ≤2h | US $50,000+ | 46% | Color, material, size, logo, packaging, graphic |

| HUITONG RAPID PROTOTYPE & SUPPLY COMPANY LIMITED | Unknown, CN | Not Specified | Machining, Casting, Moulds | 100% | ≤4h | US $30,000+ | 25% | Limited details |

| Shanghai Yunyan Prototype And Mould Manufacture Factory | Shanghai, CN | Multispecialty Supplier | Mold Making, Silicon Molding, Design | 100% | ≤3h | US $60,000+ | 38% | Tooling, material, wall thickness, design, polyurethane, stamping die |

| Shenzhen Xiang Xin Yu Technology Co., Ltd. | Shenzhen, CN | Custom Manufacturer | CNC Machining, Injection Molding | 100% | ≤6h | US $100,000+ | 20% | Color, material, size, logo, packaging, graphic |

Performance Analysis

Shenzhen-based suppliers dominate responsiveness and customization depth, with two vendors achieving sub-2-hour average reply times. Shenzhen Strongd Model Technology stands out with a 46% reorder rate—the highest in the cohort—indicating strong client retention, supported by extensive customization options and consistent delivery performance. Shanghai Yunyan offers specialized mold-making and silicon casting capabilities, ideal for complex geometries and elastomeric components. Shenzhen Xiang Xin Yu reports the highest online revenue (US $100,000+), suggesting robust order volume and market presence, though its lower reorder rate warrants further inquiry into long-term client engagement. HUITONG achieves perfect on-time delivery but offers less transparency on customization scope.

FAQs

How to verify engineered product prototyping supplier reliability?

Assess on-time delivery records (target ≥98%), response efficiency (ideally ≤4h), and reorder rates as behavioral proxies for reliability. Request facility documentation or video tours to confirm in-house machining, molding, and quality control stations. Validate technical alignment by submitting test designs for quoting and timeline estimation.

What is the typical prototyping lead time?

Standard prototype production ranges from 5–15 days depending on complexity. CNC-machined parts typically take 7–10 days, while 3D-printed or cast prototypes can be delivered in 5–7 days. Add 3–7 days for international express shipping.

Do suppliers support low MOQs?

Yes, most suppliers offer minimum order quantities of 1 piece, enabling cost-effective sampling and iterative design validation. This flexibility is critical for early-stage development and startup projects.

Are customization and NDA protection available?

All listed suppliers provide multiple customization parameters, including material, color, labeling, and packaging. For IP-sensitive projects, request formal non-disclosure agreements and verify secure file-handling practices prior to sharing design files.

How are prototype costs determined?

Pricing depends on part geometry, material selection, finishing requirements, and production method. Basic 3D-printed or machined prototypes start at $0.20–$2.50 per unit, while complex multi-part assemblies or mold-integrated designs may exceed $100. Volume discounts apply for batches exceeding 10 units.