Custom Prototyping

Top sponsor listing

Top sponsor listing

HK

HK

CN

CN

About custom prototyping

Where to Find Custom Prototyping Suppliers?

China's custom prototyping sector is concentrated in the Guangdong province, particularly within the Shenzhen-Dongguan-Huizhou industrial corridor, a globally recognized hub for rapid manufacturing and innovation-driven production. This region hosts over 70% of China’s precision fabrication and additive manufacturing suppliers, supported by advanced infrastructure for CNC machining, 3D printing, sheet metal forming, and vacuum casting. Shenzhen alone accounts for more than 40% of national prototyping output, leveraging proximity to component suppliers, material distributors, and logistics networks that enable fast turnaround times and low-cost iterations.

The ecosystem thrives on vertical integration, with many manufacturers operating end-to-end capabilities—from design support and tooling to final assembly—within compact geographic zones. Buyers benefit from reduced lead times (typically 5–15 days for prototypes), access to diverse materials (including aluminum alloys, titanium, nylon, resin, and stainless steel), and competitive pricing driven by localized supply chains. The cluster also supports high flexibility for low-volume or fully customized projects, making it ideal for R&D teams, startups, and OEMs requiring agile development cycles.

How to Choose Custom Prototyping Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

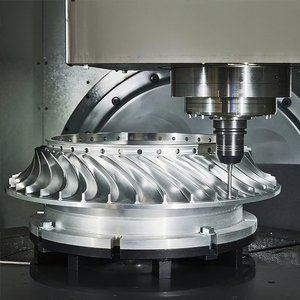

Technical Capabilities & Process Range

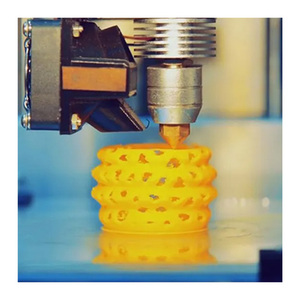

Confirm availability of core prototyping technologies: CNC milling, turning, SLA/SLS/MJF 3D printing, sheet metal stamping, vacuum casting, and hybrid molding. Prioritize suppliers offering multi-process integration to reduce outsourcing complexity. Evaluate material expertise—particularly for engineering-grade thermoplastics, metals, and composites—and verify compatibility with functional testing requirements.

Quality Assurance & Compliance

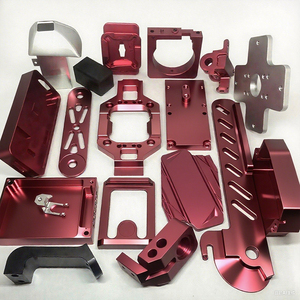

While ISO 9001 certification is not universally listed, performance metrics such as on-time delivery (target ≥98%) and documented response times (ideally ≤2 hours) serve as proxies for operational discipline. For regulated industries (medical, aerospace, automotive), request evidence of traceable quality control systems, first-article inspections, and post-processing validation (e.g., anodizing, electroplating, dyeing).

Customization Depth & Design Support

Assess customization scope beyond basic geometry adjustments. Leading suppliers offer industrial design input, STL file optimization, surface finishing options (silver, red wax, titanium coating), labeling, packaging integration, and hybrid mold solutions. Verify digital collaboration tools such as 3D scan analysis, rendering previews, and revision tracking to minimize miscommunication.

Transaction Reliability & Scalability

Analyze reorder rates (ranging from 22% to 43% among top-tier suppliers) as indicators of customer satisfaction. Cross-reference online revenue data (where available) with order fulfillment consistency. Favor suppliers with transparent minimum order quantities (MOQs often starting at 1 piece) and scalable capacity for transitioning from prototype to pilot production.

What Are the Best Custom Prototyping Suppliers?

| Company Name | Main Processes | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Customization Options | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Strongd Model Technology Co., Ltd. | Machining, Moulds, Fabrication | 98% | 43% | ≤2h | $50,000+ | Color, material, size, logo, packaging, graphic | 1 piece | $0.18–$2.58 |

| Shenzhen Js Add 3d Tech Co., Ltd. | SLA, MJF, SLM, Vacuum Casting | 100% | 29% | ≤3h | $80,000+ | Material selection, surface finish, coloring, STL optimization | 1–10 pieces | $1–$50 |

| Industrial Man Manufacturing Co., Limited | Sheet Metal Stamping, 3D Printing, Hybrid Molding | 100% | 22% | ≤5h | $20,000+ | Electroplating, tapping, rapid tooling, design files | 1 piece | $0.89–$12 |

| Shenzhen Orhong Technology Co., Ltd. | Machining, Sheet Metal, Casting | 94% | 25% | ≤2h | $20,000+ | Limited customization per listing | 10 pieces | $0.35–$19.90 |

Performance Analysis

Shenzhen Strongd Model Technology stands out with the highest reorder rate (43%) and strong responsiveness, indicating consistent service quality and client retention. Shenzhen Js Add 3d Tech demonstrates superior delivery reliability (100%) and higher online transaction volume ($80,000+), suggesting robust demand and process stability, particularly in polymer-based additive manufacturing. Industrial Man Manufacturing matches perfect on-time performance despite longer average response time, suitable for non-urgent but mission-critical prototyping needs. Orhong Technology offers competitive pricing but imposes higher MOQs and exhibits lower reorder frequency, potentially reflecting less flexible engagement models.

FAQs

How to verify custom prototyping supplier reliability?

Evaluate on-time delivery history, reorder rate, and response time as key performance indicators. Request samples to assess dimensional accuracy, surface finish, and material integrity. For high-value projects, conduct virtual factory audits to confirm equipment ownership, workforce size, and in-house processing capabilities.

What is the typical lead time for custom prototypes?

Standard lead times range from 5 to 12 days depending on complexity and technology. CNC-machined parts typically require 7–10 days, while 3D-printed prototypes can be delivered in 5–7 days. Additional time may be needed for design validation, post-processing, or international shipping via express carriers.

Do prototyping suppliers support small batch production?

Yes, most suppliers accommodate low-volume runs starting at 1 piece, especially for CNC and 3D printing services. This enables seamless transition from concept validation to pre-series manufacturing without retooling delays.

Are material certifications provided with prototypes?

While not standard, leading suppliers can provide material datasheets upon request, including resin type (e.g., ABS-like, transparent), metal alloy grade (e.g., 6061-T6 aluminum, 316L stainless steel), and processing parameters. Confirm availability during initial inquiry.

Can I submit my own CAD or STL files?

Absolutely. All listed suppliers accept digital design submissions in common formats (STL, STEP, IGES). Many offer free design reviews to optimize part orientation, wall thickness, and support structures before production begins.