Custom Pcb Prototype

Top sponsor listing

Top sponsor listing

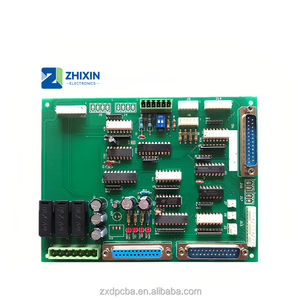

About custom pcb prototype

Where to Find Custom PCB Prototype Suppliers?

China remains the global epicenter for custom PCB prototype manufacturing, with Shenzhen emerging as the dominant hub due to its dense electronics ecosystem. The city hosts thousands of specialized PCB fabricators and assembly providers, supported by integrated supply chains for substrates, copper foils, and surface finishes. This concentration enables rapid prototyping cycles—typically 3–7 days for standard multilayer boards—and seamless transition from design validation to low-volume production.

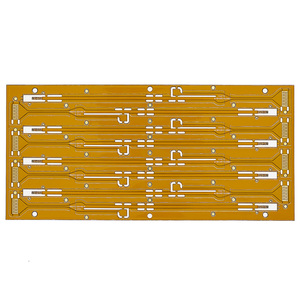

The region’s infrastructure supports end-to-end services, including Gerber file analysis, impedance control, solder mask application, and automated optical inspection (AOI). Proximity to component distributors and SMT line operators reduces logistics overhead and accelerates turnaround. Buyers benefit from competitive pricing driven by operational efficiency, with per-unit costs often 20–40% lower than equivalent Western or Southeast Asian suppliers. Scalability is further enhanced by access to advanced processes such as HDI, rigid-flex lamination, and high-frequency material handling (e.g., Rogers, Teflon).

How to Choose Custom PCB Prototype Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

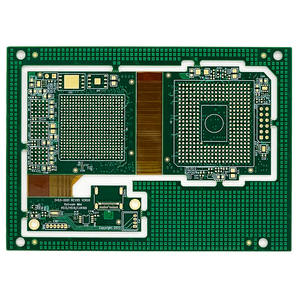

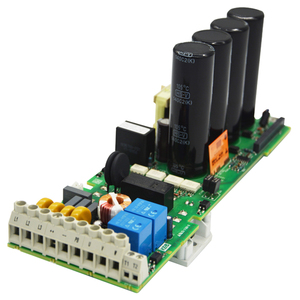

Confirm support for required layer counts (2–16+ layers), trace/space tolerances (down to 3/3 mil), and substrate types (FR-4, aluminum, polyimide). For high-speed or RF applications, verify experience with controlled impedance and dielectric thickness management. Ensure compatibility with surface finishes such as ENIG, HASL, or immersion silver.

Production & Quality Infrastructure

Assess core capabilities through objective indicators:

- In-house fabrication lines capable of processing board sizes up to 500×600mm

- Minimum drill accuracy of ±0.05mm and registration tolerance of ±0.1mm

- Implementation of AOI, X-ray inspection for BGA assemblies, and flying probe testing

- Evidence of IPC-A-600/IPC-6012 compliance in quality documentation

Cross-reference claimed lead times with on-time delivery performance (target ≥94%) and response speed (≤4 hours preferred) to validate operational responsiveness.

Transaction Reliability & Customization Support

Prioritize suppliers offering transparent order tracking, clear revision control, and structured feedback loops for design-for-manufacturability (DFM) reviews. Evaluate customization scope beyond basic layout—including silkscreen labeling, edge plating, impedance matching, and packaging configurations. Use incremental order scaling (prototype → small batch → volume) to assess consistency before full commitment.

What Are the Best Custom PCB Prototype Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity |

|---|---|---|---|---|---|---|---|

| Toptek Pcb Co., Limited | Multilayer PCB, FPC, Rigid-Flex, High Frequency | US $1,000+ | 100% | ≤2h | 66% | Not specified | Varies by listing |

| Shenzhen Fulltronics Corporation Limited | PCBA, Multilayer PCB, Double-sided PCB | US $150,000+ | 94% | ≤4h | 18% | Not specified | 1 piece |

| Shenzhen Yachuanglian Technology CO.,Ltd. | PCB, PCBA, Reverse Engineering | US $270,000+ | 81% | ≤1h | 57% | Color, material, size, logo, packaging, label, graphic | 1 piece |

| Shenzhen Kaiyuanda Electronic Technology Co., Ltd. | PCBA, Industrial Power Supplies | US $10,000+ | 100% | ≤6h | <15% | Not specified | 200 sets |

| Pinsheng Electronics Co., Ltd. | PCB, PCBA, One-stop Assembly | US $1,000+ | 100% | ≤3h | <15% | Not specified | 1 piece |

Performance Analysis

Toptek Pcb Co., Limited and Pinsheng Electronics demonstrate flawless on-time delivery records (100%), making them reliable choices for time-sensitive prototyping needs. Shenzhen Yachuanglian leads in revenue volume (US $270,000+) and offers granular customization across color, labeling, and packaging—critical for branded prototypes. While Fulltronics and Pinsheng accept single-piece orders, Kaiyuanda’s 200-set MOQ suggests focus on pre-series production rather than pure prototyping. Reorder rates indicate customer retention patterns: Toptek’s 66% rate reflects strong satisfaction, whereas sub-15% rates at Kaiyuanda and Pinsheng may signal project-based engagements or underdeveloped service loyalty. Response times are uniformly fast, with three suppliers replying within 3 hours, enabling efficient technical dialogue during DFM stages.

FAQs

How to verify custom PCB prototype supplier reliability?

Review documented adherence to IPC standards and request sample test reports for solderability, peel strength, and thermal cycling. Validate file handling protocols (Gerber, Excellon, IPC-2581) and confirm native CAM software use for DFM checks. Analyze historical performance metrics such as on-time shipment rate and dispute resolution history where available.

What is the typical lead time for a custom PCB prototype?

Standard 2-layer boards typically ship in 3–5 working days; 4–6 layer boards require 5–7 days. Expedited services (24–72 hour turnaround) are offered by select suppliers for simple designs, subject to additional fees. Add 2–4 days for PCBA when components are provided by the buyer.

Do suppliers support component sourcing for PCBA prototypes?

Yes, many offer turnkey assembly using BOMs. Capabilities vary—from basic passive integration to complex IC programming and conformal coating. Confirm availability of preferred components and whether counterfeit prevention measures (e.g., authorized distributors, lot tracing) are implemented.

Can I request impedance-controlled or high-frequency PCBs?

Several suppliers listed handle high-frequency materials (e.g., Rogers) and support impedance tolerance down to ±10%. Provide stack-up diagrams and target values during quotation. Fabricators with dedicated impedance testing equipment (TDR) should be prioritized for mission-critical applications.

What are common customization options for PCB prototypes?

Available modifications include special solder mask colors, custom silkscreen logos, panelization style, edge plating, fiducial markers, and unique packaging formats. Some suppliers also offer reverse engineering from physical samples or legacy designs.