Pcb Assembly Prototype

About pcb assembly prototype

Where to Find PCB Assembly Prototype Suppliers?

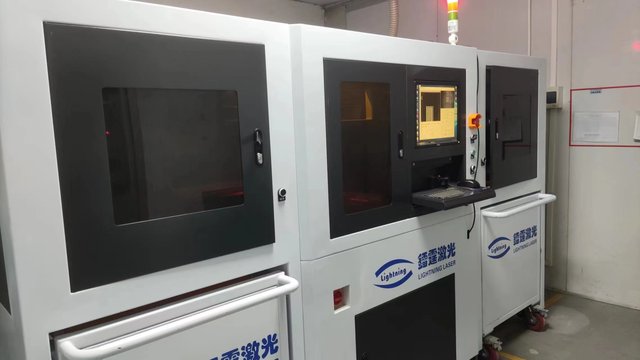

China remains the global epicenter for PCB assembly prototype manufacturing, with Shenzhen emerging as the primary hub due to its dense concentration of electronics supply chains, skilled engineering talent, and rapid prototyping infrastructure. The city hosts a high density of vertically integrated facilities capable of delivering turnkey solutions—from bare board fabrication and component sourcing to SMT assembly, testing, and packaging—within compressed timelines.

Suppliers in this ecosystem benefit from proximity to component distributors, contract manufacturers, and logistics providers, enabling agile development cycles. Lead times for functional prototypes typically range from 5–10 days for standard FR4 boards with moderate complexity. Economies of scale, localized material access, and automation-driven production lines allow cost advantages of 20–40% compared to Western-based prototyping services. This makes Shenzhen-based suppliers particularly competitive for low-volume, high-mix orders essential in product development phases.

How to Choose PCB Assembly Prototype Suppliers?

Selecting a reliable partner requires rigorous evaluation across technical, operational, and transactional dimensions:

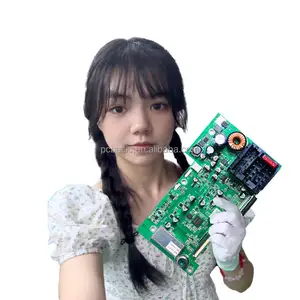

Technical & Production Capabilities

Assess whether suppliers support required stack-up configurations (e.g., rigid, flex, rigid-flex), layer counts (up to 20+ layers available), and materials (FR4, Rogers, etc.). Confirm in-house SMT lines with placement accuracy down to 0.3mm pitch components and compatibility with micro BGA or QFN packages. Automated Optical Inspection (AOI) and X-ray inspection should be standard for quality validation. Look for evidence of engineering support such as BOM optimization, component substitution, Gerber review, and design-for-manufacturability (DFM) feedback.

Quality Management Systems

Prioritize suppliers with ISO 9001 certification and adherence to IPC-A-610 Class 2 standards. Compliance with RoHS and REACH directives is critical for market access in Europe and North America. Verify process controls for solder paste application, reflow profiling, and post-assembly cleaning, especially for medical or industrial applications requiring high reliability.

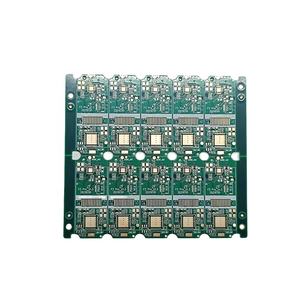

Minimum Order Quantity and Pricing Flexibility

Most suppliers accommodate prototype volumes starting at 1 piece, though pricing per unit decreases significantly at 10–100 units. Unit costs vary based on complexity: simple double-sided assemblies may start below $1.00/unit, while multi-layer, mixed-technology boards can exceed $20/unit. Transparent tiered pricing and clear MOQ terms are indicators of supplier maturity.

Transaction Reliability Indicators

Evaluate on-time delivery performance (target ≥98%), average response time (ideally ≤2 hours), and reorder rate as proxies for service consistency. High online transaction volume (e.g., >US$400,000 annually) suggests proven export experience and customer trust. Request sample boards to validate build quality, component authenticity, and labeling precision before scaling.

What Are the Best PCB Assembly Prototype Suppliers?

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Price Range (Unit) | Min. Order |

|---|---|---|---|---|---|---|---|

| Shenzhen Yongkefeng Technology Co., Ltd. | PCBA (327), Multilayer PCB (85) | 100% | 25% | ≤1h | US $70,000+ | $50–222 | 1 piece |

| Shenzhen Tailhoo Technology Co., Ltd. | PCBA, Fast Prototype Services | 100% | 40% | ≤7h | US $1,700,000+ | $0.10–10 | 1 piece |

| Tecoo Electronics Co., Ltd. | PCBA, SMT, Rigid-Flex, AOI | 98% | 37% | ≤2h | US $460,000+ | $0.60–19 | 10 pieces |

| Shenzhen Pinkuo Trading Co., Ltd. | PCBA, ICs, Electronic Modules | 100% | <15% | ≤1h | US $20,000+ | $0.45–25.99 | 1 piece |

| Shenzhen Kaiyuanda Electronic Technology Co., Ltd. | PCBA, Industrial Power Supplies | 100% | <15% | ≤6h | US $10,000+ | $2.50–3.50 | 200 sets |

Performance Analysis

Shenzhen Tailhoo stands out for cost-effective, low-volume prototyping with prices starting at $0.10/unit and extensive online sales volume, indicating strong market acceptance. Tecoo Electronics offers comprehensive engineering services—including automated optical inspection, IC programming, and BOM management—making it suitable for complex, higher-reliability applications. Shenzhen Yongkefeng provides premium assembly services targeting specialized sectors like medical devices, reflected in higher unit pricing. While several suppliers offer 1-piece MOQs, Kaiyuanda targets later-stage production with MOQs of 200+ units, suggesting a focus on pre-series rather than early prototyping. Reorder rates above 35% correlate with responsive communication and consistent quality, as seen with Tailhoo and Tecoo.

FAQs

How to verify PCB assembly prototype supplier reliability?

Cross-check ISO 9001 certification status and request copies of quality control documentation, including AOI reports, solder paste inspection logs, and first-article inspection records. Analyze supplier responsiveness, order fulfillment history, and customer reviews focused on defect rates and technical support efficacy.

What is the typical lead time for a PCB prototype?

Standard turnaround ranges from 5 to 8 business days for fabrication and assembly. Expedited 3-day services are available from select suppliers for urgent development cycles. Additional time is required if components need procurement from long-lead distributors.

Can suppliers source components globally?

Yes, most established suppliers have global component sourcing networks and can manage full turnkey builds using customer-provided BOMs. They often offer part substitution options for obsolete or restricted items and maintain relationships with authorized distributors to ensure component authenticity.

Do suppliers provide free samples or prototype discounts?

While free samples are uncommon, many suppliers offer reduced setup fees or discounted rates for initial prototype runs, especially when followed by larger-volume orders. Negotiate pilot-run pricing during early engagement stages.

How to initiate a custom PCB assembly prototype order?

Submit complete design files (Gerber, BOM, centroid data) and specify requirements such as board finish (HASL, ENIG), solder mask color, silkscreen, testing needs (functional test, flying probe), and packaging preferences. Reputable suppliers will return DFM feedback within 24 hours and confirm assembly feasibility prior to production.