Pcb Prototype And Assembly

About pcb prototype and assembly

Where to Find PCB Prototype and Assembly Suppliers?

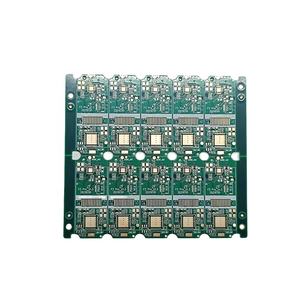

China remains the global epicenter for printed circuit board (PCB) manufacturing, with Shenzhen and Guangzhou serving as primary hubs for prototype and assembly services. These regions host vertically integrated supply chains that combine design engineering, component sourcing, surface-mount technology (SMT), and final assembly under one ecosystem. Shenzhen’s industrial infrastructure supports rapid prototyping cycles—often within 24–72 hours—while Guangzhou offers scalable production lines capable of fulfilling low- to mid-volume orders efficiently.

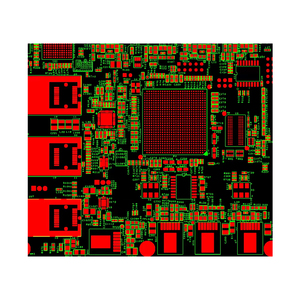

The concentration of specialized manufacturers enables streamlined workflows from Gerber file submission to functional PCBA delivery. Suppliers in these clusters leverage automated optical inspection (AOI), in-circuit testing (ICT), and reflow profiling to maintain consistency across batches. Buyers benefit from localized access to FR-4, aluminum, rigid-flex, and FPC materials, reducing material lead times by up to 40% compared to offshore alternatives. Average production costs are 20–35% lower due to optimized labor efficiency and bulk procurement of base substrates and electronic components.

How to Choose PCB Prototype and Assembly Suppliers?

Selecting a reliable partner requires rigorous evaluation across technical, operational, and transactional dimensions:

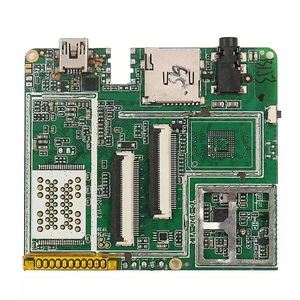

Design and Manufacturing Capabilities

Confirm support for multi-layer boards (up to 16 layers or higher), impedance control, blind/buried vias, and fine-pitch component placement (down to 0201 packages). Prioritize suppliers with in-house engineering teams offering reverse engineering, BOM optimization, and schematic validation. Key capabilities include SMT, through-hole assembly, conformal coating, and box-build integration.

Quality Assurance and Compliance

Verify adherence to IPC-A-610 Class 2 standards as a baseline. For medical, automotive, or industrial applications, demand ISO 9001 certification and compliance with RoHS, REACH, and UL marking where applicable. Insist on process documentation including solder paste inspection (SPI), AOI reports, X-ray imaging for BGA joints, and functional testing protocols.

Operational Performance Metrics

Evaluate supplier reliability using verifiable KPIs:

- On-time delivery rate ≥98%

- Average response time ≤2 hours

- Reorder rate >25% indicating customer retention

- Minimum order quantity (MOQ) flexibility down to 1 piece for prototypes

Cross-reference product listings with actual output capacity—suppliers offering hundreds of PCBA variants typically operate multiple SMT lines and have established component sourcing networks, reducing dependency on single distributors.

What Are the Best PCB Prototype and Assembly Suppliers?

| Company Name | Main Products (Listings) | Price Range (Unit) | Min. Order | On-Time Delivery | Response Time | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Shenzhen Yongkefeng Technology Co., Ltd. | PCBA (327), Multilayer PCB (85) | $50–222 | 1 piece | 100% | ≤1h | 25% | US $70,000+ |

| Tecoo Electronics Co., Ltd. | Customization-focused PCBA, High-Mix-Low-Volume | $0.50–10 | 10 pieces | 98% | ≤2h | 35% | US $460,000+ |

| Guangzhou Highleap Electronic Co., Ltd. | PCBA (541), Rigid-Flex PCB (331) | $0.50–5 | 1 piece | 94% | ≤1h | 28% | US $280,000+ |

| Shenzhen Fulltronics Corporation Limited | PCBA (214), Multilayer PCB (152) | $0.99–8.92 | 1 piece | 94% | ≤4h | 18% | US $150,000+ |

| Toptek Pcb Co., Limited | IoT & LED Prototypes, Component Sourcing | $0.80–1.20 | 1 piece | 100% | ≤2h | 66% | US $1,000+ |

Performance Analysis

Tecoo Electronics leads in scalability and customization breadth, supported by high online revenue and a robust suite of value-added services including IC programming, automated inspection, and global component sourcing. Toptek Pcb stands out with a 66% reorder rate—the highest among peers—indicating strong client satisfaction despite limited public sales volume, likely due to niche focus on IoT and fast-turn prototypes. Shenzhen Yongkefeng and Guangzhou Highleap offer full-spectrum PCBA solutions with MOQs starting at one unit, ideal for R&D and pilot runs. While Guangzhou Highleap lists over 500 PCBA configurations, its 94% on-time delivery suggests room for logistics improvement. Shenzhen-based suppliers dominate responsiveness, with three achieving sub-2-hour average reply times.

FAQs

How to verify PCB prototype and assembly supplier reliability?

Validate certifications such as ISO 9001 and assess quality documentation including first-article inspection reports, AOI logs, and solder paste analysis. Request video tours of SMT lines and component storage facilities. Analyze transaction history metrics: prioritize suppliers with on-time delivery ≥98%, response time ≤2h, and reorder rates above 25%.

What is the typical lead time for PCB prototypes?

Standard 2-layer PCB prototypes take 3–5 days, while multilayer (4–8 layer) assemblies require 7–10 days. Expedited services can reduce turnaround to 24–48 hours for bare boards and 5–7 days for assembled units, depending on component availability and design complexity.

Do suppliers support component sourcing and BOM management?

Yes, most suppliers offer full turnkey services, including component procurement, cross-referencing obsolete parts, and managing alternative substitutions. Advanced providers perform BOM cost optimization and validate part lifecycle status to mitigate obsolescence risks.

Can I request small-batch or single-unit assemblies?

Absolutely. All listed suppliers accommodate orders starting at 1 piece, making them suitable for prototyping, proof-of-concept builds, and low-volume production. Unit pricing decreases significantly at volumes exceeding 50–100 units.

What file formats are required for submission?

Standard requirements include Gerber files (RS-274X), NC drill files, bill of materials (BOM), and centroid data for pick-and-place machines. Some suppliers also accept Altium, Eagle, or KiCad project files for design review and DFM checks.