Prototype Pcb Production

Top sponsor listing

Top sponsor listing

About prototype pcb production

Where to Find Prototype PCB Production Suppliers?

China remains the global epicenter for prototype PCB production, with Shenzhen and Dalian emerging as key manufacturing hubs due to concentrated electronics ecosystems and advanced SMT infrastructure. Shenzhen hosts a dense network of vertically integrated facilities offering rapid prototyping services supported by in-house design, fabrication, and assembly lines. This region benefits from proximity to component distributors and logistics gateways, enabling express turnaround times—often under 5 days for standard prototypes. Dalian complements this with specialized engineering teams focused on high-mix, low-volume production ideal for R&D and NPI (New Product Introduction) phases.

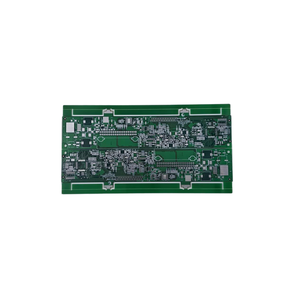

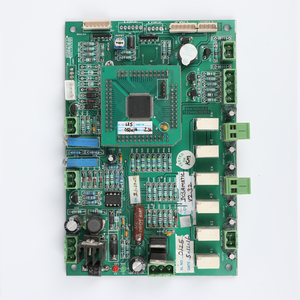

These clusters enable suppliers to deliver scalable solutions—from single-board prototypes to small-batch production—with minimal setup delays. The presence of automated SMT lines, AOI inspection systems, and DIP processing capabilities ensures consistent quality across iterations. Buyers gain access to streamlined workflows where design validation, component sourcing, and functional testing occur within tightly coordinated supply chains. Key advantages include MOQ flexibility (down to 1 piece), lead time compression (2–7 days average), and cost efficiency driven by localized labor and materials.

How to Choose Prototype PCB Production Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capabilities

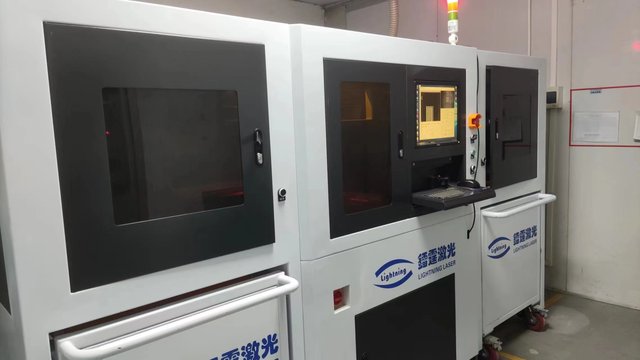

Verify that suppliers operate dedicated production lines for both rigid and flexible PCBs, with support for multilayer boards (up to 16 layers or higher). Confirm availability of core processes including laser drilling, impedance control, ENIG/OSP surface finishes, and precision solder paste printing. For turnkey PCBA services, ensure integration of SMT pick-and-place machines, reflow ovens, and post-assembly testing (ICT, FCT).

Quality Management Systems

Prioritize suppliers adhering to IPC-A-600 and IPC-A-610 standards for board acceptability and assembly quality. While formal ISO 9001 certification may not be explicitly listed in all cases, assess compliance through documented QA procedures such as incoming material inspection, in-process checks, and final reliability testing. Look for evidence of RoHS compliance and lead-free processing capabilities for export-bound electronics.

Production & Delivery Performance

Evaluate supplier reliability using quantifiable metrics:

- On-time delivery rate ≥98%

- Average response time ≤2 hours

- Reorder rate exceeding 35% indicating customer retention

- In-house production capacity confirmed via facility descriptions or process documentation

Cross-reference performance data with order volume indicators such as online revenue (e.g., >US $300,000 annually) to gauge scalability and market trust.

What Are the Best Prototype PCB Production Suppliers?

| Company Name | Location | Main Products | Monthly Output Capacity | On-Time Delivery | Avg. Response | Reorder Rate | MOQ Range | Lead Time |

|---|---|---|---|---|---|---|---|---|

| Tecoo Electronics Co., Ltd. | Shenzhen, CN | PCBA, Turnkey Assembly, OEM Prototyping | Est. 50,000+ units | 98% | ≤2h | 34% | 1–100 pcs | 5–7 days |

| Dalian Jy Electronics & Technology Co., Ltd. | Dalian, CN | Rigid/Flex PCB, SMT/DIP Assembly | Est. 40,000+ units | 100% | ≤1h | 44% | 1 pc | 3–5 days |

| Shenzhen Lihua Technology Co., Ltd. | Shenzhen, CN | PCBA, Multilayer PCB, Molded Components | Est. 80,000+ units | 93% | ≤6h | 36% | 1 pc | 5–8 days |

| Shenzhen Linghangda Technology Co., Ltd. | Shenzhen, CN | Prototype PCB, Mass Production Transition | Est. 30,000+ units | 100% | ≤9h | <15% | 1 pc | 4–6 days |

| Shenzhen Extension Electromechanical Co., Ltd. | Shenzhen, CN | Electronics Production Machinery, Screen Printers | N/A (Equipment Supplier) | 100% | ≤2h | 38% | N/A | N/A |

Performance Analysis

Dalian Jy Electronics leads in responsiveness and customer retention, achieving a 100% on-time delivery rate with sub-one-hour average responses and a 44% reorder rate—indicating strong satisfaction in prototyping accuracy and communication efficiency. Tecoo Electronics offers balanced scalability with competitive pricing and turnkey service depth. Shenzhen Lihua Technology demonstrates high output volume but slightly lower delivery consistency (93%), suggesting potential bottlenecks during peak demand. Linghangda Technology provides fast turnaround and full customization down to one-off prototypes, though its low reorder rate suggests room for improvement in long-term client engagement. Notably, Shenzhen Extension Electromechanical stands apart as an equipment provider rather than a direct PCB manufacturer, catering to firms building internal production lines.

FAQs

How to verify prototype PCB supplier reliability?

Assess verifiable performance indicators: on-time delivery rate (>97%), response speed (<2h preferred), and reorder rate (>35% indicates repeat business). Request process documentation covering solder paste inspection (SPI), AOI results, and test reports. For high-reliability applications, confirm adherence to IPC standards and ask for sample boards to evaluate finish quality and trace integrity.

What is the typical lead time for prototype PCB orders?

Standard lead times range from 3 to 7 days depending on complexity. 1–2 layer boards with no special requirements can be completed in 3–4 days; multilayer or impedance-controlled designs may require 6–8 days. Express services (24–72 hours) are available from select suppliers at premium rates.

Do suppliers support full turnkey PCBA prototyping?

Yes, multiple suppliers offer end-to-end turnkey solutions including component procurement, BOM optimization, SMT/DIP assembly, programming, and functional testing. These services reduce buyer workload and accelerate time-to-market, particularly for startups and engineering teams without in-house supply chain resources.

Can I order a single prototype PCB?

Absolutely. All listed suppliers support MOQs of 1 piece, making them suitable for initial design validation and proof-of-concept builds. Pricing scales favorably with volume, especially beyond 10–100 units.

How are customizations handled in prototype PCB production?

Suppliers support extensive customization including material selection (FR-4, Rogers, etc.), board thickness, copper weight, surface finish (HASL, ENIG, Immersion Silver), silkscreen color, and panelization style. Design files in Gerber, IPC-2581, or ODB++ formats are standard inputs. Most providers offer free DFM feedback within 24 hours of submission.