Prototype Circuit Board Fabrication

Top sponsor listing

Top sponsor listing

About prototype circuit board fabrication

Where to Find Prototype Circuit Board Fabrication Suppliers?

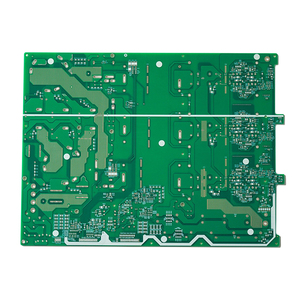

China remains the global epicenter for prototype circuit board fabrication, with Shenzhen and Suzhou serving as primary manufacturing hubs. These regions host dense electronics ecosystems integrating PCB design, rapid prototyping, component sourcing, and assembly under one supply chain. Shenzhen's specialization in high-mix, low-volume production enables fast turnaround for prototypes, while Suzhou leverages advanced multilayer and rigid-flex PCB capabilities for complex engineering applications.

The clustering effect reduces lead times through proximity to material suppliers, testing labs, and logistics networks. Buyers benefit from streamlined workflows where design validation, fabrication, and PCBA can be completed within 5–10 days for standard specifications. Localized infrastructure supports cost efficiency, with labor and overhead costs 25–40% lower than in North American or European facilities. The region’s focus on agile manufacturing makes it ideal for R&D teams requiring iterative design cycles and small-batch production runs.

How to Choose Prototype Circuit Board Fabrication Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

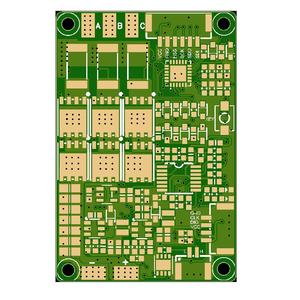

Confirm support for required layer counts (up to 20+ layers), substrate materials (FR-4, Rogers, aluminum), and trace/space tolerances (down to 3/3 mil). For high-frequency or medical-grade applications, validate expertise in impedance control, thermal management, and IPC Class 3 compliance. Suppliers should provide stack-up diagrams and DFM feedback within 24 hours of design submission.

Production & Quality Infrastructure

Assess key operational metrics:

- On-time delivery rate exceeding 97%

- Average response time ≤2 hours for technical inquiries

- In-house capabilities covering solder paste printing, SMT, THT, AOI, and functional testing

Prioritize suppliers offering full turnkey services—including component procurement, BOM optimization, and IC programming—for reduced project complexity.

Transaction Security & Scalability

Review reorder rates as an indicator of customer retention (target >30%). Use documented quality management systems—such as ISO 9001—as a baseline. Require sample boards before mass production to verify solder joint integrity, alignment accuracy, and electrical performance. Evaluate packaging and labeling customization options for traceability and branding needs.

What Are the Best Prototype Circuit Board Fabrication Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | MOQ Flexibility | Revenue Tier |

|---|---|---|---|---|---|---|---|

| Dalian Jy Electronics & Technology Co., Ltd. | PCBA, Multilayer PCB, Turnkey Assembly | 100% | ≤1h | 44% | Material, size, logo, packaging, label, boxes, cables, graphic | As low as 1 piece | US $300,000+ |

| Tecoo Electronics Co., Ltd. | PCBA, Smart Electronics OEM, Medical PCBA | 98% | ≤2h | 35% | Color, box-build, housing assembly, IC programming, global components sourcing | From 10 pieces | US $460,000+ |

| Shenzhen Mondo Technology Co., Ltd. | PCBA, 12-layer Custom Boards, FPC | 97% | ≤2h | 23% | Limited customization; strong in high-layer count and industrial controls | 1 piece (select items); typically 1,000 pcs | US $170,000+ |

| Suzhou Engine Electronic Technology Co., Ltd. | Multilayer PCB, FPC, High-Frequency PCB | 91% | ≤3h | 15% | Design, color, size, logo, packaging, engineering label | Not specified (inferred small batch) | US $50,000+ |

| Shenzhen Zhuopin High-Tech Electronics Co., Ltd. | OEM PCBA, Reverse Engineering, Low MOQ | 100% | ≤1h | <15% | Material, size, color, logo, packaging, label, graphic | As low as 10 pieces ($0.01 unit price) | US $10,000+ |

Performance Analysis

Dalian Jy Electronics leads in responsiveness and customer retention, achieving a 100% on-time delivery rate and 44% reorder rate—indicating strong client satisfaction for prototype-level projects. Tecoo Electronics combines high service volume with broad customization, including box-build and global component sourcing, making it suitable for end-to-end product development. Shenzhen Mondo excels in specialized multilayer and industrial PCBs but exhibits higher MOQs on certain lines, limiting agility for pure prototyping. Zhuopin High-Tech offers extreme cost flexibility with $0.01 pricing tiers, though its low reorder rate suggests potential gaps in post-sale support. Suzhou Engine provides niche capabilities in high-frequency and rigid-flex boards but lags in reorder performance compared to peers.

FAQs

What is the typical lead time for prototype circuit board fabrication?

Standard turnaround ranges from 5 to 7 days for 2-layer boards and 8–12 days for 4–8 layer configurations. Expedited services (3–5 days) are available at a premium. Additional time (3–7 days) applies for PCBA, depending on component availability and process complexity.

Do suppliers accept orders as small as 1 piece?

Yes, multiple suppliers—including Dalian Jy and Shenzhen Mondo—offer single-piece MOQs for both bare PCBs and assembled units, catering specifically to R&D and proof-of-concept stages.

Are RoHS and UL certifications standard?

Most suppliers comply with RoHS and use UL-certified substrates (e.g., FR-4). However, formal certification documentation must be explicitly requested. For regulated sectors like medical or aerospace, buyers should require test reports and process audits.

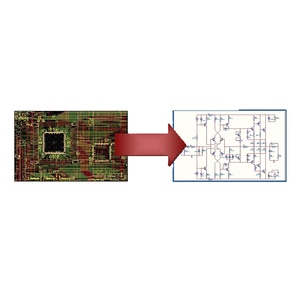

Can suppliers assist with PCB reverse engineering or cloning?

Yes, several providers—such as Shenzhen Zhuopin—list reverse engineering as a core service, enabling replication or redesign of legacy boards without original schematics.

What file formats are required for submission?

Standard requirements include Gerber files (RS-274X), NC drill files, BOM (CSV/XLS), and centroid data for assembly. Some suppliers accept Altium, Eagle, or KiCad project files for integrated DFM checks.