Pcb Design And Assembly

CN

CN

Top sponsor listing

Top sponsor listing

1/10

1/10

1/34

1/34

1/25

1/25

1/9

1/9

1/23

1/23

1/3

1/3

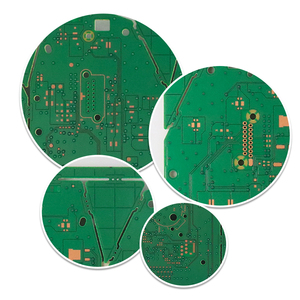

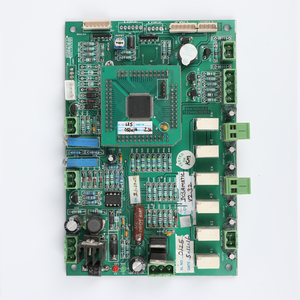

About pcb design and assembly

Where to Find PCB Design and Assembly Suppliers?

China remains the global epicenter for printed circuit board (PCB) design and assembly manufacturing, with Shenzhen and Guangzhou serving as primary hubs due to their dense ecosystems of electronics component suppliers, engineering talent, and rapid prototyping infrastructure. These regions host vertically integrated facilities capable of delivering full turnkey solutions—from schematic capture and layout design to fabrication, component sourcing, and final PCBA testing—enabling streamlined production cycles.

The concentration of technical expertise in Guangdong Province supports agile development for both low-volume prototypes and high-volume production runs. Suppliers leverage localized supply chains to reduce material lead times by 20–30% compared to offshore alternatives. Key advantages include access to multilayer and rigid-flex PCB capabilities, fast turnaround (as little as 5 days for sample batches), and competitive pricing driven by economies of scale. Buyers benefit from a mature industrial base where design houses, EMS providers, and logistics networks operate within close proximity, minimizing coordination delays.

How to Choose PCB Design and Assembly Suppliers?

Selecting a reliable partner requires rigorous evaluation across technical, operational, and transactional dimensions:

Design and Engineering Capability

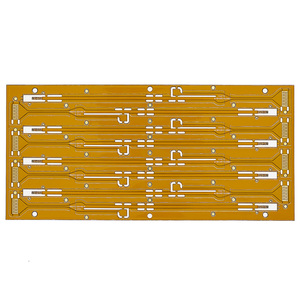

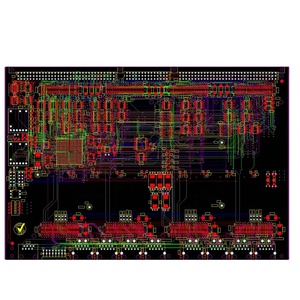

Verify proven experience in handling complex designs such as high-frequency, HDI, or rigid-flex PCBs. Assess proficiency in EDA tools (e.g., Altium Designer, Cadence) and ability to support reverse engineering, cloning, or BOM generation. Suppliers offering one-stop design-to-assembly services should demonstrate structured workflows covering DFM checks, impedance control, and signal integrity analysis.

Production Capacity and Technology

Evaluate technical specifications including:

- Layer count capability (up to 32+ layers for advanced multilayer boards)

- Fabrication processes: laser drilling, blind/buried vias, impedance-controlled routing

- Surface finishes: ENIG, HASL, OSP, immersion silver

- Support for FPC, rigid-flex, and metal-core PCBs

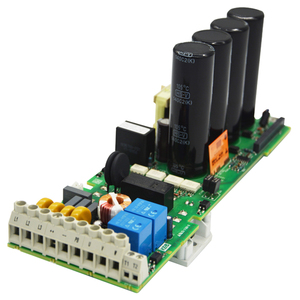

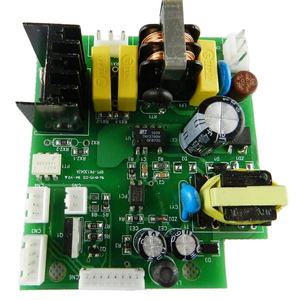

Confirm in-house SMT lines, THT assembly, automated optical inspection (AOI), and functional testing infrastructure.

Quality Assurance and Compliance

Prioritize suppliers adhering to IPC-A-610 Class 2/3 standards and ISO 9001-certified quality management systems. For export markets, compliance with RoHS, REACH, and UL certification is essential. Request documented test reports, first-article inspections, and process audits—especially for mission-critical applications in medical, automotive, or industrial sectors.

Transaction Reliability Metrics

Analyze performance indicators such as on-time delivery rate (>90% recommended), response time (<6 hours acceptable; ≤1 hour preferred), and reorder rate as proxies for customer satisfaction. High online transaction volume may indicate scalability and service consistency.

What Are the Best PCB Design and Assembly Suppliers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options | Sample MOQ | Key Strengths |

|---|---|---|---|---|---|---|---|---|

| Toptek Pcb Co., Limited | PCBA, Multilayer PCB, FPC, Rigid-Flex, High Frequency | 100% | ≤1h | 66% | US $1,000+ | N/A | 100 pcs | High reliability, consistent delivery, broad technology coverage |

| Shenzhen Shenwin Electronic Co., Ltd. | FPC, PCBA, Rigid-Flex PCB | 100% | ≤1h | - | US $100+ | Limited data | 100 pcs | Fast response, strong focus on flexible circuits |

| Guangzhou Yueneng Technology Co., Ltd. | PCB & PCBA (General) | 92% | ≤3h | <15% | US $50,000+ | Color, size, copper weight, logo, packaging, labeling | 1 pc / 1,000 pcs | High revenue volume, customization flexibility |

| Shenzhen Fengchengda Technology Co., Ltd. | PCBA, Multilayer PCB, FPC | 66% | ≤2h | 50% | US $3,000+ | N/A | 1 pc | Low MOQ, prototype-friendly, cloning services |

| Shenzhen Chanzon Technology Co., Ltd. | Transistors, Diodes, SMD LEDs, Other Components + PCBA | 92% | ≤6h | 16% | US $20,000+ | OEM/ODM, TWS earbuds, wireless audio PCBs | 10–100 pcs | Specialized in consumer electronics assemblies |

Performance Analysis

Toptek Pcb Co., Limited stands out with a perfect on-time delivery record and high reorder rate, indicating strong operational stability and client retention. Its multispecialty verification suggests adherence to broader quality protocols. Shenzhen Shenwin matches Toptek in delivery reliability and responsiveness but lacks reorder transparency, warranting further due diligence. Guangzhou Yueneng reports the highest online revenue, suggesting robust order throughput, though its sub-15% reorder rate implies potential gaps in long-term satisfaction. Shenzhen Fengchengda offers exceptional flexibility with single-piece sampling but shows lower delivery consistency (66%), making it better suited for prototyping than volume production. Chanzon Technology focuses on niche consumer electronics like Bluetooth audio devices, offering low MOQs ideal for startups and innovators.

FAQs

What is the typical lead time for custom PCB design and assembly?

Standard lead times range from 5–7 days for simple double-sided PCBs with assembly, extending to 12–15 days for multilayer or impedance-controlled boards. Expedited services (3-day turnaround) are available from select suppliers at a premium.

Do PCB suppliers offer free samples?

Free samples are uncommon; most suppliers charge nominal fees covering material and setup costs. Some may waive fees for orders exceeding 1,000 units. Prototypes typically cost between $0.50–$5.00 per unit depending on complexity.

Can I request customized PCB specifications?

Yes, most suppliers support customization of layer count, board thickness, copper weight, surface finish, solder mask color, silkscreen, and packaging. Advanced options include impedance control, blind vias, and impedance-matched routing for high-speed signals.

What are common MOQs for PCB assembly?

MOQs vary: prototype orders start at 1 piece, while cost-effective production batches begin at 100–1,000 pieces. Some suppliers offer scalable pricing tiers, reducing per-unit cost significantly at higher volumes.

How to verify supplier quality before placing an order?

Request factory audit reports, sample test results (e.g., AOI, X-ray, ICT), and references from similar industry clients. Conduct video walkthroughs of production lines and inquire about QC checkpoints, component sourcing policies (authorized distributors only), and traceability systems.