Pcb Assembly Techniques

Top sponsor listing

Top sponsor listing

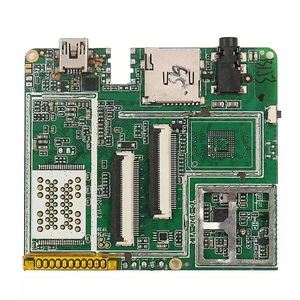

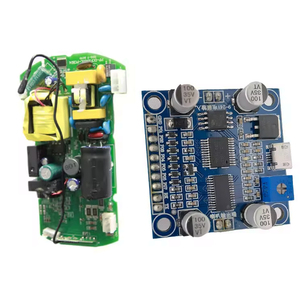

About pcb assembly techniques

Where to Find PCB Assembly Techniques Suppliers?

China remains the global epicenter for advanced PCB assembly services, with Shenzhen emerging as the dominant hub due to its dense concentration of electronics manufacturers, component distributors, and engineering talent. The city hosts over 70% of China’s high-mix, low-volume PCBA suppliers, supported by integrated supply chains that enable rapid sourcing of ICs, passives, and specialized substrates. This ecosystem reduces material lead times by 40–60% compared to non-specialized regions.

Suppliers in this cluster leverage automated SMT lines, reflow ovens, AOI (Automated Optical Inspection), and X-ray inspection systems to ensure precision in assembling components as small as 01005 packages and fine-pitch BGAs. Many offer turnkey solutions encompassing BOM sourcing, reverse engineering, IC programming, and rigid-flex assembly. Buyers benefit from scalable production capabilities—ranging from prototype runs (1–10 pieces) to medium volumes (up to 10,000 units/month)—with average lead times of 5–12 days for assembly after Gerber file submission.

How to Choose PCB Assembly Techniques Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

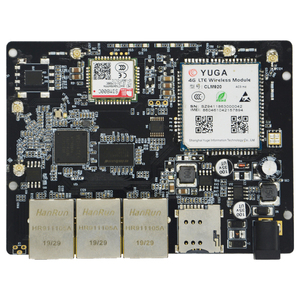

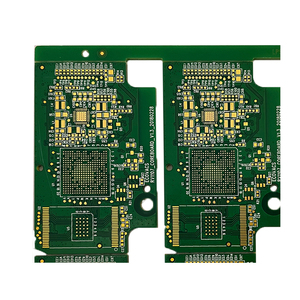

Confirm support for required assembly techniques: surface-mount technology (SMT), through-hole (THT), mixed-technology, or microelectronics packaging. Evaluate compatibility with substrate materials (e.g., FR4, Rogers, polyimide) and layer counts up to 16-layer boards. For high-reliability applications, verify availability of conformal coating, underfilling, and thermal management processes.

Quality Management Systems

Prioritize suppliers demonstrating adherence to IPC-A-610 Class 2 or Class 3 standards. While formal ISO 9001 certification is not explicitly stated in available data, consistent on-time delivery rates ≥98% and use of AOI/solder paste inspection suggest structured quality controls. Look for evidence of RoHS compliance and traceability in component sourcing, particularly for medical, automotive, or aerospace-grade assemblies.

Production Capacity & Responsiveness

Assess key performance indicators:

- On-time delivery rate >98%

- Average response time ≤2 hours

- Reorder rate exceeding 35% (indicative of customer satisfaction)

- Support for small MOQs (as low as 1 piece) and quick-turn prototypes

Cross-reference service claims with actual product listings—suppliers offering IC programming, reverse engineering, or rigid-flex assembly typically maintain dedicated process workflows and skilled engineering teams.

Transaction Security and Sampling

Utilize secure payment mechanisms where available, especially for initial orders. Request sample boards to validate solder joint quality, component placement accuracy, and labeling precision. Benchmark against internal design specifications before scaling to volume production. Confirm packaging methods to prevent ESD damage during shipping.

What Are the Best PCB Assembly Techniques Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Features |

|---|---|---|---|---|---|---|

| Tecoo Electronics Co., Ltd. | PCBA (989), Other PCB & PCBA (145) | 98% | ≤2h | 35% | US $460,000+ | IC programming, reverse engineering, rigid-flex, AOI, BOM assembly, cloning, color/material/logo customization |

| Shenzhen Yongkefeng Technology Co., Ltd. | PCBA (327), Multilayer PCB (85) | 100% | ≤1h | 25% | US $70,000+ | OEM/ODM design, turnkey assembly, component sourcing, PCB cloning |

| Shenzhen Wanfeng Technology Co., Ltd. | PCB Prototype, PCBA Manufacturing | 100% | ≤1h | 55% | US $420,000+ | Quick-turn assembly, Gerber-based production, label/logo/material/color customization |

| Toptek Pcb Co., Limited | High-Frequency PCB, 5G Baseband PCBA | 100% | ≤2h | 66% | US $1,000+ | SMT manufacturing, component sourcing, turnkey PCBA, high-frequency board support |

Performance Analysis

Tecoo Electronics leads in product breadth and revenue volume, supporting complex assemblies including reverse engineering and high-precision BOM builds. Shenzhen Wanfeng stands out for customer retention (55% reorder rate) and responsiveness, ideal for iterative development cycles. Toptek Pcb demonstrates exceptional loyalty metrics with a 66% reorder rate, suggesting strong post-sale reliability despite lower public revenue disclosure. All top-tier suppliers offer sub-2-hour response times and 100% on-time delivery, critical for agile prototyping and time-sensitive deployments. Suppliers like Yongkefeng provide multilayer and FPC assembly, indicating capability for compact, high-density designs.

FAQs

What certifications should PCB assembly suppliers have?

While explicit ISO or IPC certification is not listed in the provided data, buyers should request proof of compliance with IPC-A-610, ISO 9001, or IATF 16949 (for automotive). Verify implementation through process documentation, inspection reports, and audit trails for critical assemblies.

What is the typical lead time for PCB assembly?

Standard turnaround ranges from 5 to 12 business days after design file approval. Quick-turn services can deliver within 3–5 days for simple boards. Complex assemblies involving BGAs, blind vias, or custom component sourcing may extend to 15 days.

Do suppliers support small MOQs and prototyping?

Yes, all listed suppliers accommodate MOQs as low as 1 piece, making them suitable for R&D, testing, and low-volume commercialization. Unit pricing decreases significantly at volumes above 100 units.

Can I customize PCB color, silkscreen, and packaging?

Yes, multiple suppliers list customization options for solder mask color, silkscreen labels, logos, material type, and protective packaging. These are standard offerings for brand differentiation and traceability.

How to initiate a PCB assembly order?

Prepare complete design files in Gerber format, BOM (Bill of Materials) with part numbers and quantities, and any special instructions (e.g., no substitutions, specific test points). Submit to the supplier for quotation. Most respond within 1–2 hours with DFM feedback and pricing.