Pcb Assembly Process

CN

CN

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

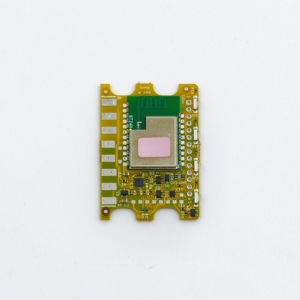

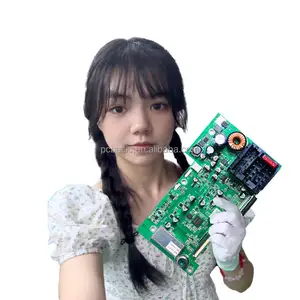

About pcb assembly process

Where to Find PCB Assembly Process Suppliers?

China remains the global epicenter for PCB assembly manufacturing, with key industrial hubs concentrated in Shenzhen, Suzhou, and Dongguan. These regions host vertically integrated facilities that combine printed circuit board (PCB) fabrication with surface mount technology (SMT), through-hole technology (THT), and final testing under one roof. Shenzhen leads in high-mix, low-to-medium volume production, particularly for prototyping and new product introduction (NPI) services, while Suzhou specializes in large-scale OEM/ODM operations with automated SMT lines capable of handling complex multilayer boards.

The ecosystem benefits from localized supply chains—components, substrates, stencils, and test fixtures are sourced within 50km, reducing lead times by up to 40% compared to offshore alternatives. Most suppliers offer turnkey solutions including PCB fabrication, component procurement, assembly, programming, functional testing, and custom packaging. Buyers can expect standard lead times of 5–10 days for prototypes and 15–20 days for mass production runs, with express options available at a premium. Cost advantages range from 20–35% over North American or European assemblers due to lower labor and operational overheads.

How to Choose PCB Assembly Process Suppliers?

Procurement decisions should be guided by technical capability verification, quality assurance systems, and transactional reliability metrics:

Quality & Compliance Standards

Confirm adherence to IPC-A-610 Class 2 or Class 3 standards for electronic assemblies. ISO 9001 certification is essential for process control; for medical, automotive, or aerospace applications, demand IATF 16949, AS9100, or ISO 13485 compliance. RoHS and REACH declarations must be provided for environmental conformity. Request access to DFM (Design for Manufacturability) reports and first-article inspection (FAI) documentation prior to production.

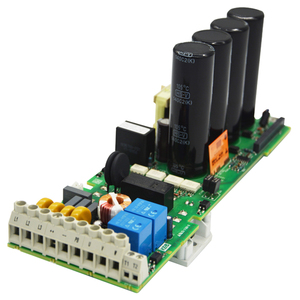

Production Capability Assessment

Evaluate core technical parameters:

- SMT placement accuracy: ±0.025mm for fine-pitch components (e.g., QFN, BGA)

- Component size compatibility down to 01005 packages and pitch as small as 0.3mm

- In-house capabilities covering single-sided, double-sided, and multilayer PCBAs up to 32 layers

- Support for rigid, flex, and rigid-flex board technologies

- Functional testing infrastructure including AOI, X-ray inspection, and ICT/FCT

Cross-reference equipment specifications with on-time delivery performance (target ≥98%) and response time (<5 hours) to assess operational efficiency.

Transaction & Risk Mitigation

Utilize secure payment methods with milestone-based releases tied to production checkpoints. Prioritize suppliers offering free DFM analysis and prototype samples before full-scale rollout. Verify component traceability through batch lot tracking and anti-counterfeit sourcing policies. For long-term contracts, insist on annual factory audits and continuous improvement reporting.

What Are the Best PCB Assembly Process Suppliers?

| Company Name | Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| ShenZhen Nova Semiconductor Co., Ltd | Brand Holder | PCBA design, Prototype & Mass Production | US $110,000+ | 98% | ≤3h | 33% | Gerber review, 3D preview, labeling, packaging | 1–50 pcs depending on service |

| Suzhou Engine Electronic Technology Co., Ltd. | Multispecialty Supplier | Industrial Control PCB, Smart Devices | US $50,000+ | 100% | ≤3h | <15% | Color, size, logo, engineering support | 1 piece |

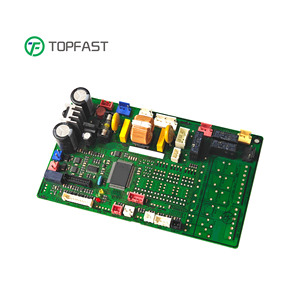

| Shenzhen Fumax Technology Co., Ltd. | Custom Manufacturer | Turnkey Electronics, Rigid-Flex PCBA | US $5,000+ | 100% | ≤5h | <15% | Material, color, label, test jig, packaging | 1 piece |

| Toptek Pcb Co., Limited | Multispecialty Supplier | Multilayer PCB, FPC, 5G Baseband PCBA | US $1,000+ | 100% | ≤1h | 66% | Limited customization noted | 1 piece |

Performance Analysis

Toptek Pcb Co., Limited stands out with a 66% reorder rate and sub-hour response time, indicating strong customer retention and service agility despite lower revenue volume. ShenZhen Nova Semiconductor demonstrates robust scalability with high transaction volume and 98% on-time fulfillment, making it suitable for medium-to-high volume buyers requiring consistent output. Suzhou Engine Electronic and Shenzhen Fumax offer full turnkey services with extensive customization but exhibit lower reorder rates, suggesting room for improvement in post-sale engagement. All top-tier suppliers support MOQs of 1 piece, enabling cost-effective prototyping and iterative development cycles.

FAQs

How to verify PCB assembly supplier quality?

Request copies of ISO certifications and IPC membership status. Conduct remote or on-site audits to validate SMT line configuration, solder paste inspection (SPI) systems, and ESD-safe environments. Review sample boards for solder joint integrity, component alignment, and cleanliness.

What is the typical lead time for PCB assembly?

Prototypes take 5–7 days; mass production (1,000+ units) requires 15–20 days. Expedited services can reduce turnaround to 72 hours for simple designs, subject to component availability.

Do suppliers handle component sourcing?

Yes, most offer BOM-based procurement with options for consigned materials. Top suppliers maintain relationships with authorized distributors to ensure genuine parts and mitigate counterfeit risk.

Can I get a free sample for testing?

Many suppliers provide free samples after engineering validation, especially for orders exceeding 100 units. Some charge a nominal setup fee refundable upon order placement.

What file formats are required for submission?

Standard requirements include Gerber files (RS-274X), NC drill files, BOM (CSV/XLS), and centroid data. For advanced features like impedance control or blind vias, stack-up diagrams and layer sequencing must be specified.