Prototype Electronics Assembly

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About prototype electronics assembly

Where to Find Prototype Electronics Assembly Suppliers?

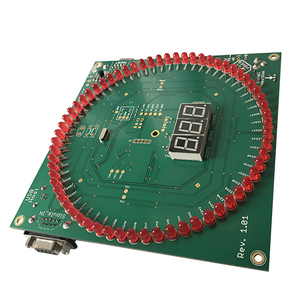

China remains the global hub for prototype electronics assembly, with Shenzhen and Dalian emerging as key manufacturing clusters due to their advanced electronics ecosystems. These regions host vertically integrated facilities that combine PCB fabrication, component sourcing, SMT/DIP assembly, and testing under one roof, enabling rapid prototyping cycles. Shenzhen’s proximity to semiconductor suppliers and logistics gateways allows for lead times as short as 5–7 days for low-volume prototypes, while Dalian offers cost-competitive labor and growing technical expertise in high-mix, low-volume production.

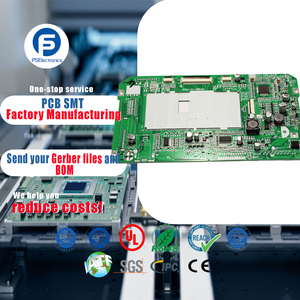

The concentration of EMS (Electronics Manufacturing Services) providers in these zones supports agile development, particularly for startups and R&D departments requiring fast turnaround. Suppliers typically operate automated SMT lines capable of handling 01005 components, micro BGAs, and double-sided assemblies. Localized supply chains reduce material procurement delays by up to 40% compared to offshore alternatives, with many offering one-stop services from Gerber file review to functional testing and box build. Buyers benefit from scalability—prototypes can transition seamlessly into small-batch production without retooling.

How to Choose Prototype Electronics Assembly Suppliers?

Evaluate potential partners using the following criteria to ensure technical reliability and transaction security:

Technical Capabilities & Compliance

Confirm adherence to IPC-A-610 Class 2 standards for electronic assemblies as a baseline. For medical, automotive, or industrial applications, require ISO 13485 or IATF 16949 certification. Verify compatibility with common design formats (Gerber, Excellon, BOM, Pick-and-Place files) and support for mixed-technology assembly (SMT + through-hole). RoHS compliance is standard; request material declarations for lead-free or halogen-free requirements.

Production Infrastructure Assessment

Key indicators of operational maturity include:

- Automated optical inspection (AOI) and X-ray inspection for BGA joints

- In-house stencil printing, reflow, and wave soldering capabilities

- Support for multilayer, rigid, flex, and aluminum PCBs

Cross-reference supplier claims with on-time delivery performance (target ≥98%) and response time metrics (ideally ≤2 hours) to assess service responsiveness.

Procurement & Quality Safeguards

Utilize secure payment methods with milestone-based releases tied to prototype delivery and testing. Request first-article inspections (FAI) and test reports (ICT, FCT) before approving批量 production. Prioritize suppliers offering free DFM (Design for Manufacturability) feedback to minimize rework. For IP protection, sign NDAs and verify data-handling policies prior to file submission.

What Are the Best Prototype Electronics Assembly Suppliers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Dalian Jy Electronics & Technology Co., Ltd. | PCBA, OEM/ODM Services | 100% | ≤1h | 44% | US $300,000+ | Boxes, cables, labeling, software duplication | 1 piece | $0.10–1.00 |

| Hongrong (Shenzhen) Electronics Co., Ltd. | OEM PCBA, Voltage Stabilizers | 98% | ≤3h | 56% | US $160,000+ | Color, material, reverse engineering, PCB cloning | 5 pieces | $0.80–3.15 |

| Shenzhen Chengjieda Industry Limited | PCBA, Solar Inverters, UPS | 94% | ≤2h | 30% | US $40,000+ | Logo, packaging, graphic, size | Not specified | Not specified |

| Pinsheng Electronics Co., Ltd. | Multilayer, Aluminum PCBAs | 100% | ≤3h | <15% | US $1,000+ | Not specified | 1 piece | $1.00–5.50 |

| Shenzhen Kaiyuanda Electronic Technology Co., Ltd. | Industrial Power Supplies, SKD PCBA | 100% | ≤6h | <15% | US $10,000+ | Not specified | 200 sets | $2.50–3.50 |

Performance Analysis

Dalian Jy Electronics stands out for its high reorder rate (44%) and sub-hour response time, indicating strong customer satisfaction and operational agility—ideal for iterative prototyping. Hongrong Electronics demonstrates exceptional repeat business (56% reorder rate), suggesting robust quality control and customization depth, including reverse engineering and software duplication. While Shenzhen Kaiyuanda and Pinsheng Electronics report perfect on-time delivery records, their lower reorder rates (<15%) may reflect transactional rather than long-term buyer relationships. Suppliers offering MOQs of 1–5 pieces provide maximum flexibility for early-stage development, whereas those requiring 200+ units are better suited for pre-production batches.

FAQs

How to verify prototype electronics assembly supplier reliability?

Request copies of quality management certifications (ISO 9001, IPC membership), facility audit reports, and customer references. Validate testing procedures such as AOI, ICT, or burn-in testing. Analyze response consistency and technical detail in quotations to gauge engineering competence.

What is the typical lead time for electronic prototypes?

Standard turnkey assembly takes 5–10 days for 1–100 units, depending on complexity. Multilayer or HDI boards may require an additional 3–5 days. Expedited services (3-day turnaround) are available from select suppliers at a premium.

Do suppliers support small MOQs for prototypes?

Yes, most leading suppliers accept orders starting from 1 piece, especially for double-sided or mixed-technology assemblies. This enables cost-effective validation before scaling to volume production.

Can I customize packaging, labeling, or firmware?

Advanced suppliers offer full customization, including branded packaging, serialized labels, cable harness integration, and firmware flashing. Confirm software duplication and encryption support if applicable.

How are intellectual property and design files protected?

Reputable manufacturers sign NDAs and maintain secure data transfer protocols. Verify file access controls and ask whether designs are reused or shared with third parties. Opt for suppliers with documented IP protection policies.