Custom Spring Prototyping

1/24

1/24

1/3

1/3

1/3

1/3

1/3

1/3

1/22

1/22

1/3

1/3

1/34

1/34

0

0

0

0

1/3

1/3

1/1

1/1

1/28

1/28

1/3

1/3

1/1

1/1

1/34

1/34

1/17

1/17

1/3

1/3

1/26

1/26

1/3

1/3

About custom spring prototyping

Where to Find Custom Spring Prototyping Suppliers?

China remains the global hub for precision spring prototyping, with key manufacturing clusters in Guangdong and Zhejiang provinces driving innovation and cost efficiency. Shenzhen and Dongguan specialize in rapid CNC machining and 3D printing integration, enabling sub-48-hour prototype turnaround for complex geometries. Ningbo and surrounding regions focus on high-volume die and compression spring production, leveraging localized steel supply chains to reduce material costs by 15–25% compared to Western suppliers.

These industrial ecosystems support vertically integrated operations—from wire drawing and heat treatment to finishing and assembly—within compact geographic zones. Buyers benefit from agile production models capable of fulfilling low-volume prototypes (MOQ: 1 piece) and scaling to mass production (up to 10,000+ units). Average lead times range from 7–15 days for custom prototypes, with select suppliers offering express 5-day services using automated CNC and SLS/SLA 3D printing platforms. Localized tooling and molding capabilities further enhance customization flexibility for non-standard dimensions, coatings, and packaging.

How to Choose Custom Spring Prototyping Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional criteria:

Technical & Material Capabilities

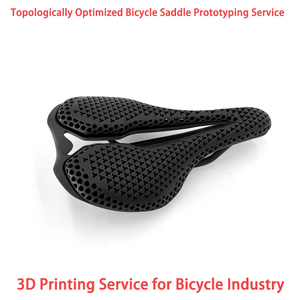

Confirm access to multi-axis CNC coiling machines, CNC milling centers, and additive manufacturing systems (SLS/SLA) for hybrid prototyping. Preferred materials include stainless steel (304, 316), titanium, phosphor bronze, and high-carbon spring steel. Suppliers should support tolerance ranges down to ±0.02mm and provide detailed process validation reports upon request.

Quality Assurance Systems

While formal ISO 9001 certification is not universally listed, prioritize suppliers demonstrating structured quality control through documented on-time delivery rates (>95%) and verifiable reorder rates. Look for evidence of in-process inspection protocols, load testing, and fatigue cycle validation—especially for torsion, extension, and high-tension applications.

Customization & Design Support

Evaluate digital engineering capacity by assessing responsiveness to design submissions. Top-tier suppliers offer free DFM (Design for Manufacturability) feedback within 24 hours and support file formats including STEP, IGES, and DWG. Capabilities such as color coding, laser marking, custom packaging, and resin coating indicate advanced finishing options.

Production Scalability Verification

Cross-reference online revenue indicators and product listing volumes to gauge operational scale. Facilities with over 300 active machining listings typically maintain dedicated R&D cells and batch-processing infrastructure. On-site video audits or facility walkthroughs are recommended to verify automation levels and inventory management systems before long-term commitments.

What Are the Best Custom Spring Prototyping Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Main Product Focus | Prototyping MOQ | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Ningbo Inunion Import And Export Co., Ltd. | Zhejiang, CN | US $890,000+ | 100.0% | ≤2h | 41% | Compression, Torsion, Die Springs | 1 piece | $0.02–1.50 |

| Torch Mold Limited | Guangdong, CN | US $130,000+ | 95% | ≤2h | 33% | CNC Machined Metal & Plastic Parts | 1 piece/unit | $0.16–3.38 |

| Dongguan New Creation Technology Company Limited | Guangdong, CN | US $70,000+ | 95% | ≤4h | 40% | 3D Printed Resin & Precision Machining | 1 set/piece | $0.90–39.00 |

| Shenzhen Huayisheng Precision Manufacturing Co., Ltd. | Guangdong, CN | US $10,000+ | 77% | ≤1h | 50% | Custom Compression & Retaining Springs | 100–10,000 pieces | $0.30–10.00 |

| Shenzhen Reteck Model Co., Ltd. | Guangdong, CN | US $2,000+ | 100.0% | ≤7h | - | Rapid 3D Printing & CNC Milling | 1 piece | $0.98–9.90 |

Performance Analysis

Ningbo Inunion leads in reliability and scalability, combining a 100% on-time delivery rate with the lowest per-unit pricing and full customization support. Torch Mold and Dongguan New Creation offer balanced capabilities for mixed-material prototypes, integrating CNC and 3D printing workflows. Shenzhen Huayisheng stands out for high-reorder demand (50%), though its higher MOQs suggest stronger alignment with mid-volume production. Reteck Model excels in speed-to-prototype with single-piece feasibility and competitive 3D printing rates, despite lower transaction volume. Buyers seeking tight tolerances and small-batch agility should prioritize suppliers with sub-10-hour response times and documented design iteration support.

FAQs

How to verify custom spring prototyping supplier reliability?

Assess performance metrics including on-time delivery rate (>95% ideal), response time (≤4h preferred), and reorder rate (≥30% indicates satisfaction). Request sample test reports for load deflection, stress relaxation, and salt spray resistance where applicable. Validate design compatibility through preliminary DFM analysis before order placement.

What is the typical lead time for spring prototypes?

Standard CNC-machined or coiled prototypes require 7–12 days. 3D-printed variants can be delivered in 5–8 days. Express services may reduce timelines to 3–5 days at a premium. Add 3–7 days for international air shipping depending on destination.

Can I request fully customized spring designs with branding?

Yes. Most suppliers support full dimensional, material, and finish customization. Additional services include laser engraving, colored coatings, custom packaging, and logo imprinting. Provide technical drawings or 3D models for accurate quoting.

Are samples available before bulk production?

Sample orders are widely supported, often at minimal cost ($0.02–$20 per unit) and MOQs as low as one piece. Some suppliers credit sample fees toward subsequent production runs exceeding 500 units.

What materials are commonly used in custom spring prototyping?

Stainless steel (304/316) dominates for corrosion resistance. Carbon steel, titanium, inconel, and phosphor bronze serve specialized applications requiring high strength, temperature resistance, or electrical conductivity. Plastic springs are prototyped via 3D printing for non-load-bearing assemblies.