Spring Service Prototype

Top sponsor listing

Top sponsor listing

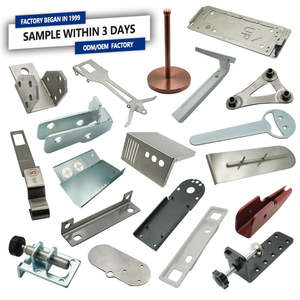

About spring service prototype

Where to Find Spring Service Prototype Suppliers?

China remains a central hub for precision spring and rapid prototyping services, with key manufacturing clusters in Guangdong, Sichuan, and Hebei provinces. Dongguan in Guangdong hosts specialized suppliers integrating CNC machining, sheet metal fabrication, and custom spring production—enabling end-to-end prototype development. Cangzhou in Hebei focuses on export-oriented supply chain integration, supporting low-volume, high-mix orders with strong logistics coordination. Sichuan-based providers combine mold-making expertise with metal forming capabilities, particularly for automotive and industrial equipment prototypes.

These regional ecosystems offer vertically integrated workflows—from raw material sourcing to finishing treatments like anodizing and heat treatment—reducing lead times by up to 30% compared to fragmented supplier models. Buyers benefit from localized access to tooling, metrology labs, and secondary processing (e.g., laser cutting, wire forming), enabling rapid iteration. Typical advantages include MOQs as low as 1 piece, average lead times of 7–15 days for machined prototypes, and cost reductions of 20–40% due to competitive labor and overhead rates.

How to Choose Spring Service Prototype Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical & Production Capabilities

Confirm the supplier’s ability to handle both spring-specific and general prototype requirements. Look for evidence of:

- In-house CNC turning, milling (including 5-axis), and sheet metal fabrication

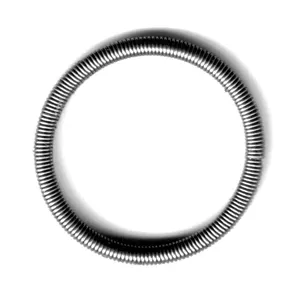

- Spring manufacturing processes: compression, extension, torsion, and flat springs in stainless steel, titanium, POM, or brass

- Secondary operations: color anodizing, black oxide coating, precision welding, and assembly

- Design support for DFM (Design for Manufacturability) optimization

Cross-reference service listings with product diversity; top-tier suppliers typically maintain 100+ active prototype-related listings across machining, molding, and metal forming categories.

Quality Assurance & Compliance

While formal certifications (e.g., ISO 9001) are not explicitly stated in available data, performance indicators suggest quality discipline. Prioritize suppliers with:

- On-time delivery rates ≥95%

- Reorder rates exceeding 25%, indicating client retention

- Response times under 2 hours, reflecting operational responsiveness

- Documented customization options including material specifications, dimensional tolerances, and surface finishes

Customization & Transaction Reliability

Evaluate flexibility in handling small-batch and prototype-specific demands:

- Minimum Order Quantities (MOQs) starting at 1 piece for CNC prototypes

- Pricing transparency: $0.05–$3.38 per unit depending on complexity and material

- Customization scope covering size, color, logo, packaging, and engineering drawings

- Online revenue exceeding US $150,000/year as an indicator of sustained commercial activity

Use incremental engagement—start with sample orders—to validate quality consistency before scaling.

What Are the Best Spring Service Prototype Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization Support |

|---|---|---|---|---|---|---|

| Cangzhou Deeplink International Supply Chain Co., Ltd. | Sheet Metal Fabrication (3,252); Machining Services (246) | 100% | 50% | ≤1h | US $5,000+ | Color, material, size, logo, packaging, label, graphic |

| Dongguan Junyi Hardware Co., Ltd. | Sheet Metal Fabrication (167); Springs (28); Machining Services (154) | 100% | 43% | ≤3h | US $150,000+ | Material variety: stainless steel, POM, titanium alloy |

| Sichuan Kunshuo Import And Export Trading Co., Ltd. | Machining Services (272); Springs (114); Moulds (54) | 100% | 30% | ≤3h | US $10,000+ | Single-piece CNC prototypes; aluminum and steel machining |

| Torch Mold Limited | CNC Fabrication, Wire Forming, Custom Springs | 95% | 25% | ≤2h | US $150,000+ | Size, material, drawing, design, painting, assembly, coloring |

| Huateng Metal Products(Dongguan) Co., Ltd. | Custom Springs, CNC Turning, 3D Printing | 100% | 25% | ≤1h | US $270,000+ | Brass, nylon, PC; heat treatment, black oxide, precision drawing |

Performance Analysis

Cangzhou Deeplink stands out for high reorder rate (50%) and rapid response, though its lower reported online revenue suggests niche-scale operations. Dongguan Junyi and Huateng Metal demonstrate robust technical breadth with strong revenue performance and full compliance in on-time delivery. Sichuan Kunshuo offers deep specialization in spring-integrated prototypes with single-piece MOQ flexibility. Torch Mold provides extensive customization but slightly lower delivery reliability (95%). Suppliers based in Dongguan leverage proximity to Shenzhen’s electronics and hardware ecosystem, enhancing agility for iterative design projects.

FAQs

What materials are commonly used in spring service prototypes?

Stainless steel, titanium alloy, brass, POM (Delrin), aluminum, and carbon steel are standard. Material selection depends on load requirements, corrosion resistance, and operating environment. Some suppliers also support plastic injection and 3D-printed functional prototypes using nylon or PC.

What is the typical lead time for a custom spring or CNC prototype?

Rapid prototypes typically take 7–15 days from design approval to shipment. Complex multi-process assemblies or those requiring tooling may require 20–25 days. Express services are often available for urgent requests.

Can suppliers produce prototypes with certification compliance?

While explicit ISO or RoHS certifications are not listed, many suppliers adhere to equivalent internal quality systems. Buyers should request process documentation, inspection reports, and material test certificates when regulatory compliance is required.

Do suppliers support low-volume production after prototyping?

Yes, most suppliers transition seamlessly from prototype to batch production, with scalable MOQs ranging from 10 to 1,000 units. This enables cost-effective validation and pilot runs prior to mass manufacturing.

How should buyers initiate a prototype project?

Submit detailed technical drawings (STEP, DWG, or PDF), specify materials, tolerances, surface treatments, and intended application. Reputable suppliers will provide DFM feedback, quotation within 24 hours, and prototype samples within two weeks.