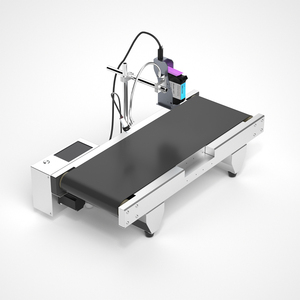

Expiry Date And Batch Number Printing Machine

About expiry date and batch number printing machine

Where to Find Expiry Date and Batch Number Printing Machine Suppliers?

China remains the central hub for coding and marking equipment manufacturing, with key supplier clusters in Hubei, Guangdong, and Zhejiang provinces. Wuhan, Hubei—home to multiple industrial inkjet technology firms—hosts vertically integrated production facilities specializing in thermal inkjet (TIJ) and continuous inkjet (CIJ) systems. Guangzhou-based suppliers focus on high-speed industrial coders with advanced customization capabilities, while Yiwu and Jiangxi regions offer cost-competitive manual and semi-automatic solutions ideal for small to mid-volume producers.

These regional ecosystems enable streamlined component sourcing, from printheads to conveyor integration modules, reducing lead times by 20–30% compared to decentralized manufacturing models. Facilities typically maintain in-house R&D, assembly, and testing units within compact geographic zones, supporting rapid prototyping and order fulfillment. Buyers benefit from scalable production options, with standard machine delivery timelines averaging 15–30 days and expedited builds available for urgent deployments.

How to Choose Expiry Date and Batch Number Printing Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Verify compatibility with required printing methods: TIJ for high-resolution static codes, CIJ for high-speed production lines, or thermal transfer for non-porous surfaces. Ensure machines support essential data fields—expiry dates, batch/lot numbers, barcodes, and multilingual text. CE certification is critical for compliance in European markets, while food-grade ink compatibility must be documented for FMCG and pharmaceutical applications.

Production and Customization Capacity

Assess supplier flexibility through the following criteria:

- Minimum factory area exceeding 1,000m² indicating established infrastructure

- Demonstrated capability in OEM/ODM services, including logo integration, label formatting, and multi-line code programming

- Support for variable print heights (up to 25.4mm), graphic encoding, and sensor-based triggering

Cross-reference product listings with response time and reorder rate metrics to gauge service reliability and scalability.

Quality Assurance & Transaction Security

Prioritize suppliers with documented quality control processes and third-party validation. On-time delivery rates above 90% and response times under 4 hours correlate with stronger operational discipline. Utilize secure payment mechanisms and request pre-shipment inspection rights. Conduct sample testing to evaluate print adhesion, smudge resistance, and long-term durability under real operating conditions.

What Are the Best Expiry Date and Batch Number Printing Machine Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Wuhan Willita Industrial Co., Ltd. | Hubei, CN | Inkjet Printers (241), Sealing Machines (115) | US $40,000+ | 96% | ≤3h | <15% | 1 set | $31.15–$469 |

| Guangzhou Prima Technology Co., Ltd. | Guangdong, CN | Customization-focused inkjet systems | US $380,000+ | 91% | ≤3h | 45% | 1 set | $170–$6,700 |

| Willita Ink Jet Technology (Wuhan) Co., Ltd. | Hubei, CN | TIJ Printers, Conveyor-integrated Coders | US $320,000+ | 100% | ≤2h | 17% | 1 piece/set | $30.80–$689 |

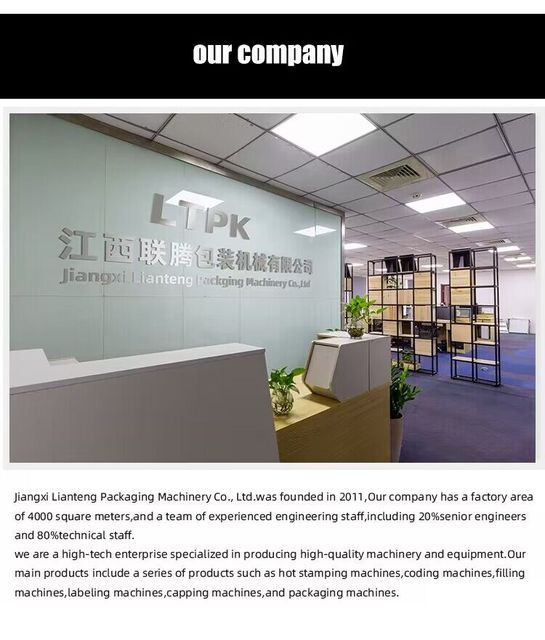

| Jiangxi Lianteng Intelligent Equipment Co., Ltd. | Jiangxi, CN | Filling & Labeling Machines (499+ combined) | US $90,000+ | 80% | ≤6h | <15% | 1 set | $40–$1,600 |

| Yiwu Jeta International Trading Co,. Ltd. | Zhejiang, CN | Embossing & Ribbon Coding Machines | US $220,000+ | 100% | ≤4h | <15% | 1 set | $45–$558 |

Performance Analysis

Guangzhou Prima stands out for high-end industrial CIJ systems and extensive customization options, supported by a strong reorder rate of 45%, reflecting customer satisfaction with technical support and adaptability. Willita Ink Jet Technology (Wuhan) and Yiwu Jeta achieve perfect on-time delivery records, with sub-4-hour response times enhancing buyer confidence. Wuhan Willita offers broad product diversity at competitive price points, though lower reorder rates suggest room for improvement in post-sale engagement. Jiangxi Lianteng provides entry-level solutions suitable for budget-conscious buyers but lags in delivery performance. For mission-critical applications, prioritize suppliers with CIJ/TIJ engineering expertise, proven integration experience, and robust after-sales service frameworks.

FAQs

What certifications should expiry date printing machine suppliers have?

CE certification is essential for market access in Europe and indicates compliance with safety and electromagnetic compatibility standards. ISO 9001 registration reflects formalized quality management systems. For food and pharmaceutical use, confirm compatibility with FDA-compliant or food-safe inks.

What is the typical MOQ and lead time?

Most suppliers offer MOQs of 1 set, enabling low-volume procurement. Standard lead times range from 7–15 days for stock models. Custom configurations may require 20–30 days depending on complexity. Express shipping options are commonly available.

Can these machines print on curved or uneven surfaces?

Yes, CIJ and handheld TIJ printers are designed for non-contact printing on irregular surfaces, including bottles, tubes, and flexible packaging. Sensor-triggered models ensure consistent placement regardless of product shape or speed variation.

Do suppliers offer integration with conveyors or production lines?

Multiple suppliers, including Willita and Jiangxi Lianteng, provide conveyor-integrated coding systems. Confirm compatibility with existing line speeds and interface requirements (e.g., PLC synchronization, photoelectric sensors) before procurement.

How to evaluate print durability and readability?

Request sample prints on your actual packaging material. Test resistance to smudging, moisture, and abrasion. Use barcode verification tools to assess scan accuracy over time, especially under storage or transport conditions.