Factory Io Palletizer

About factory io palletizer

Where to Find Factory IO Palletizer Suppliers?

China remains the global epicenter for automated palletizing solutions, with key manufacturing clusters in Henan and Shandong provinces driving innovation and cost efficiency. Henan, home to over 50% of China’s industrial automation suppliers, offers integrated robotics and packaging machinery ecosystems centered around Zhengzhou and Xinxiang. These hubs benefit from mature supply chains for servo motors, control systems, and structural steel, reducing component procurement lead times by 20–30%. Shandong’s Qingdao region specializes in turnkey packaging lines, leveraging coastal logistics and proximity to steel processing centers to achieve 15% lower material costs compared to inland counterparts.

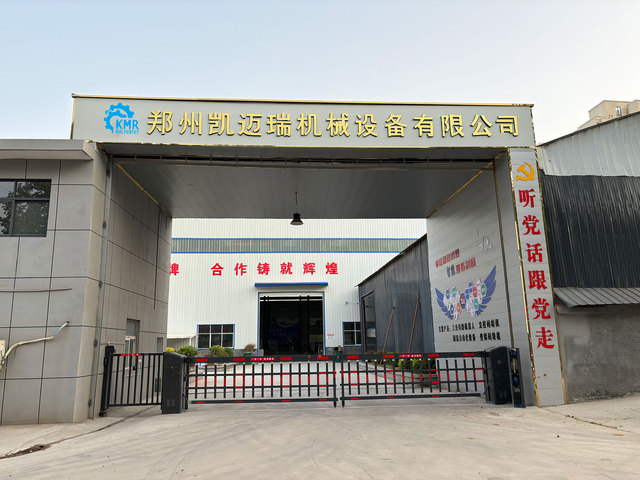

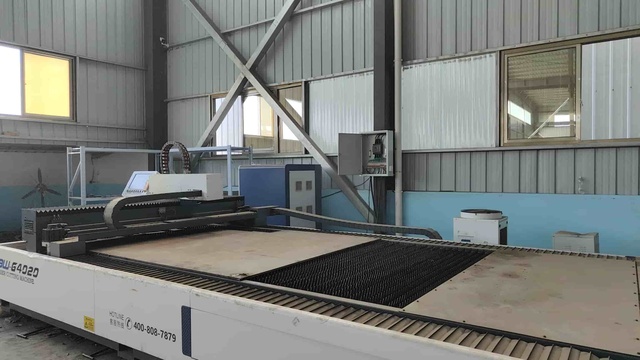

The concentration of engineering talent and vertically integrated production facilities enables rapid prototyping and scalable manufacturing. Suppliers in these regions typically operate end-to-end workflows—from CNC fabrication and robotic integration to final assembly—within single campuses, ensuring tighter quality control. Buyers can expect standard lead times of 30–60 days for fully automatic systems, with customization cycles extending by 10–20 days depending on complexity. The regional infrastructure supports both high-volume OEM contracts and low-MOQ custom builds, making it ideal for diverse industrial applications including food & beverage, chemicals, and logistics.

How to Choose Factory IO Palletizer Suppliers?

Procurement decisions should be guided by structured evaluation criteria focused on technical capability, production reliability, and transactional safeguards.

Technical and Quality Compliance

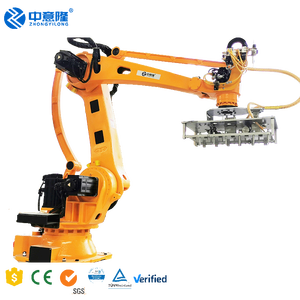

Verify adherence to international standards such as CE marking for EU market compliance and ISO 9001-certified quality management systems. For robotic palletizers, confirm integration of recognized components (e.g., Mitsubishi, Siemens, or ABB controls) and request validation of safety protocols including emergency stop circuits and risk assessment documentation. Suppliers should provide test reports for load capacity, cycle time accuracy, and operational stability under continuous duty.

Production Capacity Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum factory area of 3,000m² for full-line automation production

- In-house engineering teams capable of PLC programming and HMI interface design

- CNC machining, laser cutting, and robotic welding capabilities

Cross-reference declared output capacity with verified on-time delivery performance (target ≥97%) and reorder rates to assess operational consistency.

Customization and Transaction Security

Prioritize suppliers offering configurable options for payload (10–30kg), layer pattern logic, conveyor integration, and IoT-enabled monitoring. Confirm support for client-specific branding, color schemes, and control panel localization. Utilize secure payment mechanisms such as escrow services, and insist on pre-shipment inspection clauses. Request sample units for functional testing—particularly for gripper durability and stacking precision—before committing to bulk orders.

What Are the Best Factory IO Palletizer Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Verified As |

|---|---|---|---|---|---|---|---|

| Qingdao Ausense Packing Equipment Co., Ltd. | Shandong, CN | Packaging Line, Wrapping Machines, Conveyors | 100% | ≤3h | <15% | US $40,000+ | - |

| Cast Automation SL | Spain | Packaging Line, Wrapping Machines, Furniture Components | Not specified | ≤25h | Not specified | Not specified | - |

| Henan Zhong Yi Long Machinery Equipment Co., Ltd. | Henan, CN | Servo Gantry Palletizers, Robotic Systems | 100% | ≤2h | <15% | US $100,000+ | Custom Manufacturer |

| Henan Ocean Machinery Equipment Co., Ltd. | Henan, CN | Cobot Palletizers, Robotic Arms | 97% | ≤2h | 35% | US $820,000+ | Custom Manufacturer |

| Zhangjiagang Simbormachinery Co., Ltd. | Jiangsu, CN | Robot Palletizing Arms, EOAT Grippers | 100% | ≤3h | 100% | US $140,000+ | - |

Performance Analysis

Suppliers from Henan province demonstrate strong responsiveness and competitive pricing, with multiple vendors offering compact cobot-based palletizers in the $12,000–$15,000 range. Henan Ocean Machinery stands out with a 35% reorder rate and high online revenue, indicating consistent customer satisfaction and export activity. Zhangjiagang Simbormachinery exhibits exceptional loyalty metrics (100% reorder rate), suggesting robust after-sales support and reliable machine performance despite lower price points starting at $3,500. Cast Automation SL targets premium markets with high-capacity European-designed systems priced above $87,000, though limited response speed may affect service agility. Qingdao Ausense focuses on integrated packaging lines, positioning itself for clients seeking full-system automation rather than standalone units.

FAQs

How to verify factory IO palletizer supplier reliability?

Validate certifications through official registries and request factory audit reports or video walkthroughs of production floors. Analyze transaction history, focusing on on-time delivery consistency and customer feedback related to technical support and system uptime. Third-party inspection services can verify machine specifications prior to shipment.

What is the typical lead time for automated palletizers?

Standard models require 30–45 days for production and testing. Custom configurations involving specialized end-of-arm tooling or SCADA integration may extend timelines to 60 days. Air freight adds 5–10 days for international delivery, while sea shipping ranges from 20–40 days depending on destination.

Can suppliers integrate palletizers into existing factory IO systems?

Yes, most established manufacturers support communication protocols such as Modbus TCP, Profibus, or EtherNet/IP for seamless integration with factory automation networks. Confirm compatibility with your PLC platform and request I/O point lists and data mapping documentation during the quotation phase.

Do suppliers offer samples or pilot units?

Sample availability varies. Some manufacturers provide demo units at partial cost, especially for orders exceeding one set. Pilot systems for testing in live environments are often negotiable upon deposit, with fees credited toward full-scale deployment.

What customization options are available for factory IO palletizers?

Common modifications include adjustable lift height (up to 3 meters), multi-pallet format handling, barcode-triggered stacking patterns, and IoT connectivity for remote monitoring. Suppliers also offer bespoke safety enclosures, paint finishes, and bilingual HMI interfaces tailored to regional operations.