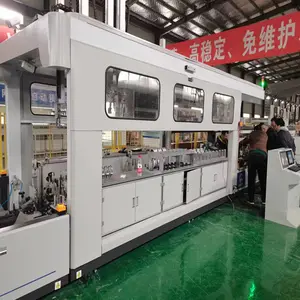

Factory Loading

Top sponsor listing

Top sponsor listing

1/3

1/3

0

0

CN

CN

1/22

1/22

1/3

1/3

CN

CN

1/16

1/16

1/30

1/30

1/3

1/3

1/3

1/3

CN

CN

0

0

1/18

1/18

1/3

1/3

CN

CN

1/7

1/7

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

CN

CN

1/22

1/22

About factory loading

Where to Find Factory Loading Equipment Suppliers?

China remains the central hub for factory loading equipment manufacturing, with key industrial clusters in Shandong and Hebei provinces driving innovation and scale. Shandong hosts a high concentration of intelligent automation and material handling system producers, particularly around Jinan and Qingdao, where integrated supply chains reduce component procurement lead times by up to 25%. Hebei’s Anping County specializes in wire-based machinery and structural loading systems, leveraging regional expertise in metal processing and mesh fabrication.

These regions support vertically integrated production ecosystems, combining CNC machining, robotic assembly, and quality testing under one roof. This integration enables suppliers to maintain tighter control over production timelines and customization workflows. Buyers benefit from reduced unit costs—typically 20–30% below Western equivalents—alongside faster turnaround, with standard orders fulfilled in 30–60 days. The proximity of raw material suppliers, engineering talent, and export logistics centers further enhances operational efficiency for both bulk and bespoke procurement.

How to Choose Factory Loading Equipment Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Production Infrastructure Verification

Confirm suppliers operate dedicated production lines with documented capacity. Prioritize manufacturers with minimum 5,000m² facilities and in-house capabilities in CNC machining, welding, and automated assembly. Evidence of R&D investment—such as custom control systems or PLC programming teams—indicates adaptability for specialized loading configurations.

Quality Assurance Protocols

Insist on ISO 9001 certification as a baseline for quality management. For international deployments, verify CE marking compliance to meet EU safety standards. Request test reports for load-bearing components, motor performance, and electrical control panels. Suppliers with documented on-time delivery rates above 97% and response times under 2 hours demonstrate consistent operational discipline.

Customization & Transaction Security

Evaluate customization depth: leading suppliers offer modifications in frame material, conveyor speed, loading height, color coding, and integration with existing ERP/MES systems. Use secure payment mechanisms such as third-party escrow, especially for first-time engagements. Review reorder rates as a proxy for customer satisfaction—rates exceeding 30% suggest reliable performance and post-sale support.

What Are the Best Factory Loading Equipment Suppliers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Response Time | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|

| Jinan Saibainuo Technology Development Co., Ltd. | Pet Food Processing Machines, Feed Processing Machines, Grain Product Making Machines, Bean Product Processing Machinery | Color, material, size, logo, packaging, label, graphic | 93% | ≤2h | 33% | US $1,300,000+ |

| Longkou Huijinda Intelligent Equipment Co., Ltd. | Plastic Extruders, Linear Robots, CNC Milling Machines, Laser Cutting Machines | N/A | 100% | ≤1h | <15% | US $10,000+ |

| Jiaozuo Shuangyi Filter Co., Ltd. | Filtration systems (custom branding) | Color, material, size, logo, packaging, label, graphic | 100% | ≤2h | 35% | US $60,000+ |

| Shandong Xulida Machinery Co., Ltd. | Gluing Machines, Wood Based Panels Machinery, Board Making Machinery, Collaborative Robots | N/A | 100% | ≤1h | <15% | US $10,000+ |

| Anping County Laien Wire Mesh Machine Manufacturing Co., Ltd. | Cold-rolled ribbed wire mesh machines | Color, material, size, logo, packaging, label, graphic | 100% | ≤1h | <15% | US $30,000+ |

Performance Analysis

Jinan Saibainuo stands out with the highest reported revenue and a 33% reorder rate, indicating strong market acceptance and repeat business, despite a slightly lower on-time delivery rate at 93%. Longkou Huijinda, Shandong Xulida, and Anping Laien achieve perfect 100% on-time delivery records, with sub-2-hour response times, reflecting robust internal coordination. Jiaozuo Shuangyi leads in customer retention with a 35% reorder rate, suggesting effective post-sale engagement. While several suppliers lack detailed customization disclosures, those offering full branding and material flexibility are better suited for OEM integration and private-label deployment.

FAQs

How to verify factory loading equipment supplier reliability?

Validate certifications through official registries and request facility audit reports covering production workflows, material traceability, and QC checkpoints. Assess responsiveness and technical clarity during inquiry stages as indicators of long-term service capability.

What is the typical lead time for customized loading systems?

Standard units ship in 30–45 days. Custom-engineered systems require 45–75 days depending on complexity, including design approval, component sourcing, and pre-shipment testing. Expedited builds may reduce timelines by 10–15% with premium fees.

Do suppliers support global shipping and customs clearance?

Yes, experienced exporters provide FOB, CIF, and DDP shipping terms. Confirm inclusion of export documentation, CE declarations, and compatibility with destination-country electrical and safety codes. Sea freight is standard for full-container loads; air shipping is viable for urgent spare parts.

Is sample testing available before bulk ordering?

Most suppliers offer prototype or sample units upon request. Expect partial cost recovery for samples, typically 30–50% of production value, refundable against confirmed orders. Testing should include load cycle endurance, motor stability, and interface compatibility.

What customization options are commonly offered?

Suppliers frequently modify equipment dimensions, load capacity, drive systems, control panels, and safety enclosures. Branding options include custom paint, logos, labels, and packaging. For seamless integration, confirm compatibility with existing SCADA or factory automation platforms prior to order finalization.