Factory Robot Arm

Top sponsor listing

Top sponsor listing

0

0

1/3

1/3

1/3

1/3

1/33

1/33

CN

CN

1/15

1/15

1/3

1/3

1/3

1/3

0

0

1/28

1/28

1/24

1/24

1/7

1/7

1/1

1/1

1/3

1/3

0

0

1/3

1/3

1/11

1/11

About factory robot arm

Where to Find Factory Robot Arm Suppliers?

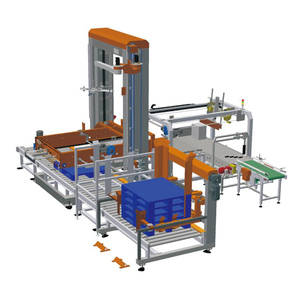

China remains the global epicenter for industrial robot arm manufacturing, with concentrated supplier clusters in Shandong, Fujian, and Guangdong provinces. These regions host vertically integrated production ecosystems that combine precision engineering, automation R&D, and scalable assembly lines. Shandong’s Qingdao and Jinan zones specialize in packaging and material handling robotic systems, supported by localized steel and conveyor component suppliers that reduce lead times by 15–25%. Fujian’s Fuzhou industrial base focuses on articulated and collaborative robots, leveraging regional expertise in sensor integration and motion control systems.

Suppliers in these hubs operate dedicated production lines for 4-axis palletizing, 6-axis welding, and CNC-integrated robotic arms, enabling rapid prototyping and batch customization. Buyers benefit from mature supply networks where motor, gearbox, and controller components are sourced within 50km, ensuring shorter production cycles (typically 20–35 days for standard configurations). The presence of in-house design teams allows for CAD-based layout adjustments, including custom end-effectors, strapping mechanisms, and conveyor integration—critical for automated factory deployment.

How to Choose Factory Robot Arm Suppliers?

Procurement decisions should be guided by technical verification, production transparency, and transactional reliability:

Technical & Quality Compliance

Confirm adherence to ISO 9001 standards as a baseline for quality management. For export markets, CE certification is essential for compliance with EU machinery directives. Request test reports for repeatability accuracy (±0.02–0.05mm), payload capacity validation, and cycle life endurance (minimum 10,000-hour operational testing). Verify compatibility with common industrial protocols (e.g., Modbus, Profibus) and safety-rated control systems.

Production Capability Assessment

Evaluate core infrastructure indicators:

- Minimum factory area exceeding 3,000m² to support full-cycle manufacturing

- In-house CNC machining, welding, and robotic calibration capabilities

- Dedicated engineering teams for customization (CAD/CAM/PLC programming)

Cross-reference declared output capacity with online revenue metrics and reorder rates to assess scalability and customer retention.

Transaction & Risk Mitigation

Prioritize suppliers offering third-party payment protection and post-delivery inspection clauses. Analyze response time (target ≤2 hours) and on-time delivery performance (ideally ≥90%) as proxies for operational reliability. Conduct virtual factory audits to confirm automation line configuration and quality control checkpoints before order placement.

What Are the Best Factory Robot Arm Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Verified Type |

|---|---|---|---|---|---|---|---|

| Qingdao Ausense Packing Equipment Co., Ltd. | Packaging Line, Wrapping Machines, Conveyors, Robotic Arms | US $1,300,000+ | 100% | ≤2h | 22% | Yes (layout, dimensions, labeling, materials) | Custom Manufacturer |

| Ounaian Electronic Technology (Fuzhou) Co., Ltd. | Articulated Robots, Collaborative Robots, Optical Sensors | US $8,000+ | 66% | ≤3h | 50% | Limited (product-specific) | |

| Guangdong Borunte Robot Technology Co., Ltd. | Articulated Robots, Collaborative Robots, CNC Handling Systems | US $20,000+ | 66% | ≤4h | 100% | Yes (welding, palletizing, 3D laser integration) | |

| Jinan Stark Machinery Equipment Co., Ltd. | Collaborative Robots, Articulated Robots, Conveyors | US $70,000+ | 92% | ≤1h | 33% | Yes (multi-axis, high-precision applications) | |

| Jinan Lingyu International Trade Co., Ltd. | CNC Robotic Arms, Industrial Welding Robots | US $40,000+ | 90% | ≤1h | 30% | Yes (color, logo, packaging, size) | Multispecialty Supplier |

Performance Analysis

Qingdao Ausense stands out with a 100% on-time delivery rate and robust customization capacity across packaging automation systems, making it ideal for integrators requiring turnkey solutions. Jinan Stark and Jinan Lingyu demonstrate strong responsiveness (≤1h) and high delivery reliability (≥90%), indicating efficient internal coordination. Ounaian and Borunte exhibit higher reorder rates (50–100%), suggesting strong product satisfaction despite moderate delivery performance. Suppliers with verified "Custom Manufacturer" status typically offer deeper engineering support for bespoke robotic integration, while multispecialty traders may provide broader logistics flexibility but less direct process control.

FAQs

How to verify factory robot arm supplier credibility?

Validate certifications through official registries and request evidence of in-house production (e.g., facility videos, equipment lists). Analyze transaction history, focusing on consistent delivery performance and repeat business volume. Third-party inspection services can audit quality control procedures pre-shipment.

What is the typical MOQ and lead time?

Standard MOQ is 1 unit for prototype or evaluation orders. Bulk production lead times range from 20 to 40 days depending on complexity. Custom configurations with integrated vision or force feedback may require an additional 10–15 days for testing and calibration.

Can suppliers integrate robot arms into existing production lines?

Yes, many suppliers offer system integration services, including conveyor synchronization, PLC programming, and safety enclosure design. Provide CAD layouts and I/O specifications to enable accurate feasibility assessment and quotation.

Do manufacturers offer free samples or trial units?

Sample policies vary. Some suppliers offset sample costs against future bulk orders (e.g., credit upon 5+ unit purchase). Trial units are rarely offered without deposit, but remote demo access via live video feed is commonly available.

What customization options are available for industrial robot arms?

Common modifications include payload adaptation (5–200kg), reach extension, end-effector type (gripper, suction, welding torch), color coding, branding, and communication interface upgrades (EtherCAT, CANopen). Full re-engineering requires NRE fees and tooling investment, typically justified for orders exceeding 10 units.