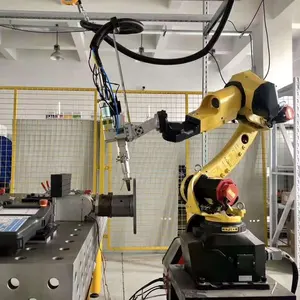

Fanuc Largest Robot

CN

CN

CN

CN

CN

CN

About fanuc largest robot

Where to Find Suppliers for the Fanuc Largest Robot?

China remains a dominant force in industrial robotics integration and automation solutions, with key supplier clusters concentrated in Shanghai, Qingdao, and Anhui. These regions host specialized engineering firms offering Fanuc-powered robotic systems, including high-payload models positioned as among the largest in their class. Shanghai and Shandong-based suppliers benefit from proximity to advanced manufacturing zones and port logistics hubs, enabling efficient export operations. The ecosystem supports both turnkey robotic workstations and modular automation components, backed by vertically integrated production capabilities.

Suppliers in these industrial centers leverage localized access to precision machining services, welding infrastructure, and control system integrators, reducing assembly lead times by 20–30% compared to offshore alternatives. Buyers gain access to scalable production environments capable of fulfilling single-unit pilot orders or multi-system deployments within 45–60 days. Cost advantages stem from optimized supply chains, with reported price points ranging from $6,500 for entry-level robotic cells to over $110,000 for fully integrated high-reach palletizing or welding stations.

How to Choose Fanuc Largest Robot Suppliers?

Selecting qualified suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Integration Expertise

Confirm demonstrated experience integrating Fanuc robotic arms—particularly high-payload models such as M-900 or 20iA series—into industrial workflows. Request case studies or project references involving material handling, palletizing, or arc welding applications. Verify compatibility with end-of-arm tooling (EOAT), safety interlocks, and PLC communication protocols (e.g., Profibus, EtherNet/IP).

Production and Quality Assurance

Assess core manufacturing competencies through the following criteria:

- In-house engineering teams specializing in robotic cell design and parametric programming

- On-site welding, CNC machining, and electrical panel fabrication capabilities

- Documented quality control processes, including pre-shipment testing of robot kinematics and cycle validation

- Compliance with ISO 9001 standards or equivalent quality management systems

Cross-reference declared response times and on-time delivery performance (where available) to gauge operational reliability. Prioritize suppliers reporting ≤7-hour average response times and 100% on-time shipment records.

Procurement Safeguards

Utilize secure payment mechanisms such as escrow services to mitigate financial risk. Require detailed product specifications, including reach, payload capacity, repeatability metrics, and controller versions (e.g., R-30iB). Conduct video audits of facility operations before order placement. Insist on functional testing at origin or third-party inspection agencies like SGS or Bureau Veritas prior to shipment.

What Are the Leading Fanuc Largest Robot Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Xiangjing (Shanghai) Mechanical and Electrical Tech Co., Ltd. | Shanghai, CN | Multi-joint material handling robots, suction cup fixtures | $24,000–44,500 | 1 set | 100% | ≤7h | 20% | Color, material, size, payload, gripper, packaging |

| Stuaa Automation (Qingdao) Co., Ltd. | Qingdao, CN | Fanuc-powered welding robots, centrifugal blower systems | $6,500–12,000 | 1 set | 100% | ≤5h | Not available | Limited |

| Shandong Oulian Intelligent Technology Co., Ltd. | Shandong, CN | Welding workstations, robotic arms with 1831mm reach | $2,500–110,000 | 1 set | 100% | ≤2h | <15% | Seam welding configurations, turning rolls |

| Anhui Gongboshi Tech. Co., Ltd. | Anhui, CN | 6-axis FANUC manipulators, collaborative robot systems | $20,900–160,000 | 1 set / 1 box | 100% | ≤21h | Not available | Basic configuration options |

| Jinan Pioneer CNC Technology Co., Ltd. | Shandong, CN | Laser welding robots, 7-axis automation cells | $40,000–60,000 | 1 set | 30% | ≤3h | 28% | Color, size, logo, graphic customization |

Performance Analysis

Xiangjing (Shanghai) offers broad customization and mid-range pricing, making it suitable for tailored material handling applications. Stuaa Automation provides cost-effective Fanuc-integrated welding solutions with strong responsiveness (≤5h) but limited customization scope. Shandong Oulian stands out for rapid communication (≤2h) and competitive pricing across a wide spectrum, though its highest-priced units suggest capability in large-scale workstation deployment. Anhui Gongboshi lists premium-priced humanoid and industrial robots, indicating focus on high-capacity automation, despite longer response cycles. Jinan Pioneer CNC targets laser-processing applications with higher-value robotic integrations but reports a significantly lower on-time delivery rate (30%), warranting logistical scrutiny. Buyers prioritizing reliability should favor suppliers with verified 100% on-time delivery and response times under 8 hours.

FAQs

How to verify Fanuc robot supplier authenticity?

Request official partnership documentation or reseller authorization from Fanuc where applicable. Validate product authenticity through serial number tracing, firmware verification, and controller branding. Cross-check company registration details and transaction history via business registries or B2B platform verification badges.

What is the typical lead time for Fanuc robotic systems?

Standard configurations typically ship within 30–45 days after order confirmation. Customized robotic cells involving structural modifications or specialized tooling may require 50–70 days. Allow additional time for international shipping: 15–25 days via sea freight to North America or Europe.

Do suppliers support global shipping and installation?

Most established suppliers offer worldwide shipping under FOB or CIF terms. Some provide remote commissioning support or on-site installation services for an additional fee. Confirm inclusion of technical manuals, wiring diagrams, and training materials in English or target language.

Are samples available for robotic systems?

Full-system sampling is uncommon due to cost and complexity. However, suppliers may offer demo videos, virtual walkthroughs, or factory acceptance tests (FAT). For subsystem validation, request sample components such as EOAT or control panels before full procurement.

What customization options are commonly offered?

Available customizations include payload adaptation, extended arm reach configurations, specialized grippers, paint color, labeling, and integration with conveyors or vision systems. Advanced modifications require engineering collaboration and may impact lead time and warranty coverage.