Fast Turn Pcb Prototype

CN

CN

About fast turn pcb prototype

Where to Find Fast Turn PCB Prototype Suppliers?

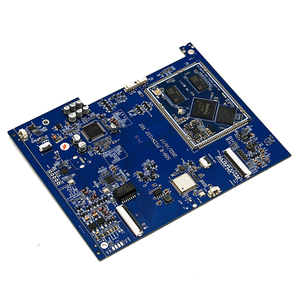

China remains the global epicenter for fast turn PCB prototype manufacturing, with Shenzhen emerging as the dominant hub due to its concentrated electronics supply chain and rapid prototyping infrastructure. The city hosts a dense network of vertically integrated facilities capable of delivering multilayer, HDI, flexible, and high-frequency PCBs within 24 to 72 hours. This ecosystem benefits from proximity to material suppliers, component distributors, and SMT assembly lines, enabling seamless transition from design to functional prototype in under five days.

Shenzhen-based manufacturers leverage advanced fabrication technologies—including laser drilling, impedance control, and automated optical inspection—to support complex designs for IoT, RF, and aerospace applications. Buyers gain access to scalable production models where low-volume prototypes (1–5 pieces) are processed alongside batch orders without lead time penalties. Key advantages include MOQs as low as one piece, pricing transparency, and digital workflows that automate DFM checks and order tracking. Localization reduces logistics overhead, with air shipping options enabling delivery to North America and Europe within 3–5 business days.

How to Choose Fast Turn PCB Prototype Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capabilities Verification

Confirm support for required stack-ups (up to 20-layer HDI), materials (e.g., FR-4, Taconic, Rogers), surface finishes (ENIG, HASL), and trace/space tolerances. For high-frequency or flex-rigid designs, verify specialized process validation through impedance reports or bend testing. Ensure Gerber file compatibility and automated DFM feedback loops to minimize revision cycles.

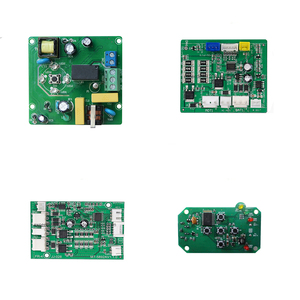

Production & Quality Infrastructure

Assess operational scale through key indicators:

- Minimum monthly output capacity exceeding 10,000 units

- In-house capabilities covering PCB fabrication, SMT assembly, and testing

- Implementation of IPC-A-600/6012 standards and AOI/X-ray inspection systems

Prioritize suppliers with documented quality management systems, even if formal ISO certification is not listed. On-time delivery rates above 95% and response times under 4 hours indicate strong service discipline.

Procurement Safeguards

Utilize secure payment frameworks that align financial risk with delivery milestones. Evaluate reorder rates as a proxy for customer satisfaction—suppliers with rates above 50% demonstrate consistent performance. Request sample builds to validate solder joint integrity, layer alignment, and electrical continuity before scaling. Confirm packaging and labeling compliance for international shipments, especially for electrostatic-sensitive assemblies.

What Are the Best Fast Turn PCB Prototype Suppliers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Price Range (USD) | Min. Order Quantity |

|---|---|---|---|---|---|---|---|

| Shenzhen Cengfeng Electronics Co., Ltd. | Multilayer PCB, HDI, FPC, High Frequency, PCBA | 100% | ≤4h | - | - | $2.69–38.89 | 1 pc |

| Shenzhen Changkeshun Technology Co., Ltd. | PCBA, Quick-Turn, Custom Fabrication | 100% | ≤3h | 25% | US $290,000+ | $0.10–2.97 | 2 pcs |

| Toptek Pcb Co., Limited | Rigid-Flex, IoT, Low-Volume Assembly | 100% | ≤2h | 66% | US $1,000+ | $0.90–1.20 | 1 pc |

| Shenzhen Wonderful Technology Co., Ltd. | Prototype Assembly, Reverse Engineering | 88% | ≤6h | 35% | US $410,000+ | $1–100 | 1 pc |

| Shenzhen Wanfeng Technology Co., Ltd. | Quick-Turn PCBA, UAV, Free DFM | 100% | ≤1h | 55% | US $420,000+ | $0.89–9.80 | 1 pc |

Performance Analysis

Suppliers like Shenzhen Cengfeng and Toptek Pcb emphasize technical versatility, supporting HDI, high-frequency, and flexible substrates ideal for R&D-intensive sectors. Toptek stands out with a 66% reorder rate and sub-$1.20 pricing, indicating strong value retention despite limited revenue visibility. Shenzhen Wanfeng excels in responsiveness (≤1h) and offers free DFM analysis, reducing design errors early in the cycle. While Shenzhen Wonderful has the highest reported online revenue, its 88% on-time delivery rate presents a potential fulfillment risk compared to peers maintaining 100%. Changkeshun provides the lowest entry price point ($0.10 at 50 pcs), making it suitable for cost-driven iterations. Buyers requiring full turnkey services should prioritize companies offering component sourcing, programming, and testing within integrated workflows.

FAQs

What certifications should fast turn PCB suppliers have?

While not all suppliers list ISO 9001 or IPC membership, adherence to RoHS and REACH environmental standards is standard practice. For regulated industries (medical, automotive), request evidence of process controls aligned with IATF 16949 or ISO 13485. Internal quality logs and first-article inspection reports can serve as interim validation.

What is the typical lead time for a fast turn PCB prototype?

Standard turnaround ranges from 24 to 72 hours for bare PCBs and 3–5 days for assembled units (PCBA). Expedited services may reduce this to 12 hours for simple 2-layer boards. Add 2–4 days for international delivery via express carriers.

Can I order a single PCB prototype?

Yes, most suppliers accommodate orders of one piece, particularly for multilayer and HDI boards. Pricing per unit decreases significantly at quantities of 5, 10, or 50, depending on complexity.

Do suppliers offer component sourcing for PCBA?

Many provide full BOM fulfillment, including active components, passives, and connectors. Verify availability lead times for long-lead ICs and whether counterfeit prevention protocols (e.g., original sourcing only) are enforced.

How can I reduce prototyping costs without compromising quality?

Optimize panel utilization by submitting multiple copies of your design in array format. Select standard materials (FR-4) and avoid exotic finishes unless necessary. Use automated quoting tools to compare pricing across layer count, thickness, and finish options.