Quick Turn Prototype Pcb

Top sponsor listing

Top sponsor listing

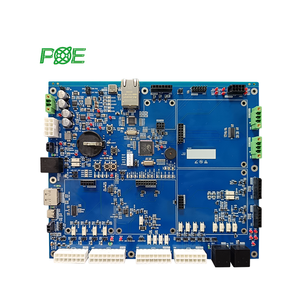

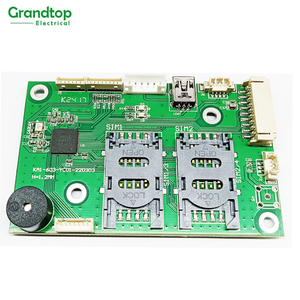

About quick turn prototype pcb

Where to Find Quick Turn Prototype PCB Suppliers?

China remains the global epicenter for rapid-turn printed circuit board (PCB) manufacturing, with Shenzhen emerging as the dominant hub for prototype and low-volume production. The city's dense ecosystem of electronics manufacturers, component distributors, and logistics providers enables accelerated development cycles—critical for startups, R&D departments, and engineering firms requiring fast turnaround. Suppliers in this region leverage vertically integrated facilities that combine PCB fabrication, surface mount technology (SMT), and through-hole assembly under one roof, reducing inter-facility delays.

The concentration of technical expertise and supporting infrastructure allows lead times as short as 24–72 hours for bare boards and 5–7 days for full PCBA. Economies of scale, access to raw materials like FR-4 and CEM-1 substrates, and proximity to semiconductor suppliers contribute to a 20–35% cost advantage over North American or European alternatives. Buyers benefit from flexible ordering models, including single-piece prototypes and small-batch runs, without sacrificing quality or delivery performance.

How to Choose Quick Turn Prototype PCB Suppliers?

Selecting a reliable partner requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capabilities & Compliance

Verify support for standard and advanced PCB specifications: layer count (1–16+ layers), surface finishes (HASL, ENIG, Immersion Silver), trace/space tolerances, and impedance control. Essential certifications include ISO 9001 for quality management and adherence to IPC-A-600/IPC-6012 standards for acceptability of printed boards. For export to regulated markets, confirm RoHS and REACH compliance documentation.

Production Capacity and Responsiveness

Assess supplier responsiveness and throughput using measurable indicators:

- Average response time ≤2 hours for inquiry resolution

- On-time delivery rate ≥98%

- Reorder rate above 25% indicating customer retention

- In-house capabilities covering PCB fabrication, SMT placement, DIP assembly, testing, and programming

Cross-reference service claims with verifiable data such as online revenue volume and order fulfillment history. Prioritize suppliers offering free Design for Manufacturability (DFM) analysis to preempt production issues.

Customization and Supply Chain Support

Evaluate options for material selection, color masking, labeling, panelization (including breakaway tabs), and component sourcing. Leading providers offer turnkey solutions encompassing BOM procurement, chip programming, and final packaging. Confirm compatibility with Gerber, Excellon, and IPC-2581 file formats to ensure seamless design transfer.

Transaction Security and Sampling

Utilize secure payment mechanisms and require sample validation before mass production. Benchmark first-article inspections against IPC Class 2 or Class 3 criteria depending on application criticality. Analyze defect rates, solder joint integrity, and alignment accuracy during sample review.

What Are the Best Quick Turn Prototype PCB Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Wanfeng Technology Co., Ltd. | PCBA, Multilayer PCB, Quick-Turn Prototypes | US $420,000+ | 100.0% | ≤1h | 66% | 1 piece | $0.98–9.80 | Color, material, size, logo, packaging, Gerber support |

| Toptek Pcb Co., Limited | IoT Prototype PCB, OEM Assembly, Low-Volume SMT | US $1,000+ | 100.0% | ≤2h | 66% | 1 piece | $0.90–1.20 | Limited customization; focus on high-reliability prototypes |

| Shenzhen Changkeshun Technology Co., Ltd. | PCB Fabrication, PCBA, Fast Prototype Services | US $290,000+ | 100.0% | ≤3h | 25% | 1–2 pieces | $0.50–5.98 | Full turnkey: components sourcing, programming, HASL/ENIG, labels |

| Fs Circuit (Shenzhen) Co., Ltd. | PCBA, FPC, Multilayer PCB, EMS Services | US $30,000+ | 100.0% | ≤4h | 27% | 1–10 pieces | $0.55–2.99 | SMT/DIP, OEM branding, graphic design, packaging |

Performance Analysis

Shenzhen Wanfeng Technology stands out with the highest recorded online revenue, fastest average response time (≤1 hour), and strong reorder rate (66%), indicating consistent service quality and client satisfaction. Their broad customization range and competitive pricing make them suitable for complex, low-volume prototype projects. Toptek Pcb Co., Limited offers tightly controlled pricing and specializes in IoT-focused prototype PCBs with high repeatability, though customization is more limited. Shenzhen Changkeshun provides comprehensive turnkey services, including component sourcing and firmware programming, ideal for buyers seeking full supply chain delegation. Fs Circuit delivers budget-friendly options with solid technical breadth across rigid, flex, and multilayer boards, albeit with slightly longer response windows.

FAQs

What is the typical lead time for quick turn prototype PCBs?

Bare PCBs can be produced in 24–72 hours, while assembled units (PCBA) typically take 5–7 days. Rush services may reduce these timelines by 24–48 hours at a premium. Processing begins upon confirmation of Gerber files and DFM approval.

Do suppliers accept single-unit prototype orders?

Yes, all listed suppliers support minimum order quantities of 1 piece, catering specifically to R&D and proof-of-concept stages. Pricing scales favorably with volume, particularly beyond 10 and 100 units.

Are DFM checks provided free of charge?

Most reputable suppliers, including Shenzhen Wanfeng and Changkeshun, offer complimentary DFM analysis to identify layout errors, spacing violations, and manufacturability risks prior to production.

Can suppliers source electronic components?

Turnkey providers like Changkeshun and Fs Circuit offer full BOM fulfillment, including active and passive components, connectors, and programmable ICs. Lead times may vary based on part availability and obsolescence status.

How are quality issues resolved post-delivery?

Buyers should confirm warranty terms and defect reporting procedures upfront. Reputable suppliers conduct 100% AOI (Automated Optical Inspection) and functional testing where applicable. Discrepancies must be reported within 7–14 days with documented evidence for rework or replacement eligibility.