Fish Net Making Machine Price

Top sponsor listing

Top sponsor listing

1/27

1/27

CN

CN

1/37

1/37

1/24

1/24

1/19

1/19

About fish net making machine price

Where to Find Fish Net Making Machine Suppliers?

China remains the central hub for fish net making machine manufacturing, with key production clusters concentrated in Jiangsu and Shandong provinces. These regions host vertically integrated supply chains combining precision engineering, textile machinery expertise, and polymer processing capabilities. Yangzhou, in particular, has emerged as a specialized center for net knitting equipment, housing multiple manufacturers with dedicated R&D units focused on monofilament handling, knotting mechanisms, and automated tension control systems.

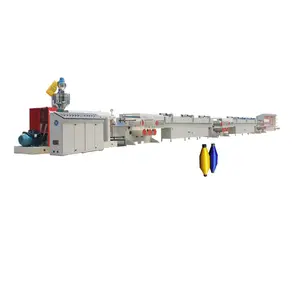

The industrial ecosystem supports rapid prototyping and scalable production, with many facilities operating under ISO-aligned quality management frameworks. Proximity to raw material suppliers—particularly polypropylene (PP), high-density polyethylene (HDPE), and nylon filament producers—enables cost efficiencies of 15–25% compared to non-Asian manufacturers. Buyers benefit from consolidated sourcing models where machine fabrication, extrusion components, and post-production testing occur within tightly coordinated networks, reducing lead times to 45–60 days for standard configurations.

How to Choose Fish Net Making Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

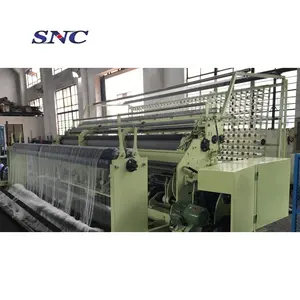

Confirm compatibility with target materials (PP, HDPE, nylon) and mesh types (square, diamond, hexagonal). Machines should support adjustable parameters including twine diameter (0.1–3mm), knot density (up to 120 knots/min), and net width (up to 12m). While explicit CE or ISO certifications are not universally declared in available data, prioritize suppliers providing detailed engineering schematics, motor specifications (typically 7.5–15kW), and evidence of electrical safety compliance.

Production Capacity Verification

Assess infrastructure indicators such as factory scale, workforce size, and in-house machining capabilities. Leading suppliers operate facilities exceeding 5,000m² with CNC-controlled assembly lines and dedicated calibration stations. Evaluate output consistency through on-time delivery rates—suppliers reporting ≥97% performance demonstrate stronger process reliability. Response time (ideally ≤5 hours) serves as a proxy for operational responsiveness and customer service integration.

Customization & After-Sales Support

Verify scope of customization: mesh size, color coding, sinker/float integration points, packaging formats, and branding options (logo imprinting, label design). Request documentation on spare parts availability, operator training programs, and remote diagnostics support. Suppliers offering modular designs enable future upgrades in speed or material range without full system replacement.

Transaction Risk Mitigation

Utilize secure payment structures such as escrow or milestone-based disbursements tied to production checkpoints. Require pre-shipment inspection (PSI) protocols and access to third-party quality verification. Analyze reorder rates as an indicator of customer satisfaction—rates above 30% suggest consistent product performance and service reliability.

What Are the Best Fish Net Making Machine Suppliers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options | Online Revenue |

|---|---|---|---|---|---|---|---|

| Wudi Jinhai Fishing Tackle Co., Ltd. | Fishing Nets, Aquaculture Traps, Fishing Tools & Accessories | 97% | ≤3h | 30% | Not specified | Mesh size, color, thickness, twine length, lead pendant, mold weight, packaging, sinkers, label, diameter, material, size, logo, monofilament, graphic, holes, dimensions, height | $100,000+ |

| CNRM Tech Co., Ltd. | Polypropylene & PE Monofilament Yarn, Net Making Equipment | 100% | ≤4h | <15% | $49,000–$59,000 | Output, color, material, size, logo, packaging, label, graphic | $400+ |

| Yangzhou Haili Precision Machinery Manufacturing Co., Ltd. | Net Machines, Spinning & Dyeing Equipment, Fishing Lines | 100% | ≤22h | - | $42,000–$100,000 | Varies by model | - |

| Yangzhou Xinyu Textile Machinery Co., Ltd. | Net Machines, Knitting Machines, Apparel Machinery Parts | 100% | ≤5h | - | $47,500–$49,500 | Standard industrial customization | - |

| Yangzhou Xinbin Textile Machinery Co., Ltd. | Net Machines, Textile Machine Parts, Plastic Extruders | 100% | ≤16h | - | $38,000–$58,000 | Mesh size, material, output configuration | - |

Performance Analysis

CNRM Tech and Yangzhou Haili achieve perfect on-time delivery records, indicating robust production planning and logistics execution. Wudi Jinhai stands out with a verified 30% reorder rate and extensive customization breadth, suggesting strong end-user satisfaction and flexible manufacturing. Yangzhou Xinbin offers the lowest entry price point at $38,000, making it a competitive option for budget-conscious buyers seeking basic automation. However, response times vary significantly—Wudi Jinhai (≤3h) and CNRM Tech (≤4h) provide superior communication efficiency compared to Yangzhou Haili (≤22h).

Price dispersion reflects machine complexity: models below $50,000 typically serve small-scale or regional fisheries, while units priced above $95,000 incorporate high-speed Japanese-style double-knotting technology and wider net-forming capacity. Buyers requiring large mesh sizes or heavy-duty trawl net production should prioritize suppliers with documented experience in offshore fishing gear applications.

FAQs

What is the typical MOQ for fish net making machines?

The standard minimum order quantity is 1 set across all major suppliers, allowing for individual procurement, pilot installations, or integration into existing production lines.

What lead time should buyers expect?

Manufacturers generally require 45–60 days for production and pre-shipment preparation. Custom configurations may extend timelines by 10–15 days depending on mechanical modifications or control system programming.

Are samples available for testing?

Full-machine sampling is uncommon due to size and cost. However, reputable suppliers can produce short-run net samples using the intended machine settings to validate mesh quality, knot strength, and material compatibility before final assembly.

Can fish net making machines handle different materials?

Yes, most modern machines support PP, HDPE, and nylon monofilaments. Operators must adjust tension, heating, and feed rates based on material elasticity and melting point. Confirm multi-material capability during technical vetting.

What after-sales services are typically offered?

Support varies but may include installation guidance, remote troubleshooting, spare parts supply, and operator training—either on-site or via video. Clarify service terms and potential travel costs prior to purchase.

How do suppliers ensure quality control?

Leading manufacturers implement in-process inspections at critical stages: frame alignment, gear synchronization, and electronic control calibration. Final testing includes continuous operation runs (8–12 hours) to verify thermal stability and knot consistency.