Flex Pcb Prototyping

CN

CN

Top sponsor listing

Top sponsor listing

CN

CN

1/24

1/24

CN

CN

1/20

1/20

CN

CN

1/23

1/23

1/34

1/34

1/37

1/37

1/25

1/25

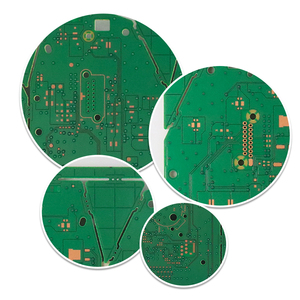

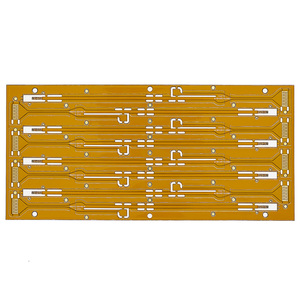

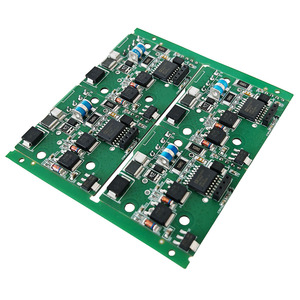

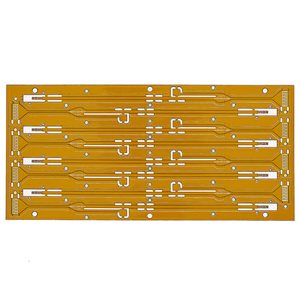

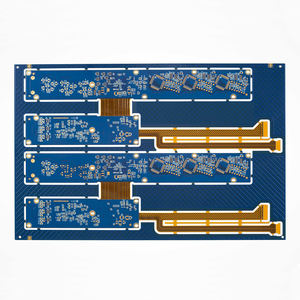

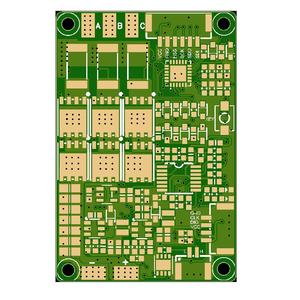

About flex pcb prototyping

Where to Find Flex PCB Prototyping Suppliers?

China remains the global hub for flex PCB prototyping, with concentrated manufacturing expertise in Shenzhen and surrounding Guangdong regions. These industrial clusters offer integrated supply chains combining material sourcing, precision fabrication, and rapid assembly—enabling turnaround times as fast as 3–5 days for simple single-layer flex circuits. The region hosts numerous specialized facilities equipped with laser drilling, automated optical inspection (AOI), and impedance-controlled processing lines, supporting both prototype development and low-volume production.

Suppliers in this ecosystem benefit from proximity to raw material suppliers (e.g., polyimide films, copper foils) and component distributors, reducing logistics overhead and enabling agile iterations. Buyers gain access to vertically aligned operations capable of handling design validation, DFM feedback, fabrication, and PCBA within a single workflow. Key advantages include scalable output from 1-piece prototypes to batch runs of 1,000+ units, competitive pricing due to optimized labor and infrastructure, and strong customization capabilities across layer count (1–6 layers), bend radius, and surface finishes (ENIG, Immersion Silver, OSP).

How to Choose Flex PCB Prototyping Suppliers?

Effective supplier selection requires structured evaluation based on technical capability, operational reliability, and transactional transparency:

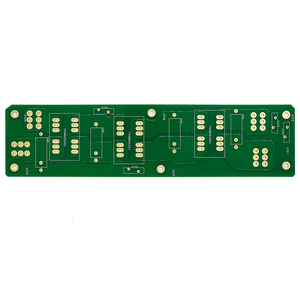

Technical & Process Capabilities

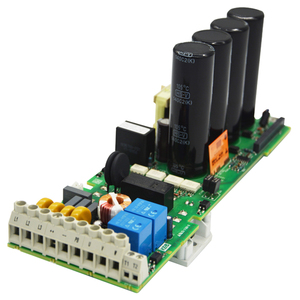

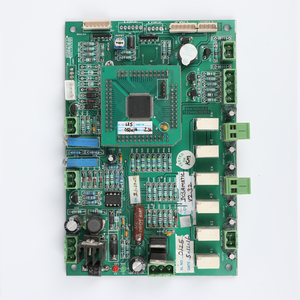

Verify that suppliers support core flex PCB requirements including controlled impedance, dynamic/flex bend specifications, and thin-profile construction (down to 0.1mm). Confirm availability of critical processes such as coverlay lamination, stiffener integration, and SMT assembly for hybrid rigid-flex builds. For high-reliability applications, assess experience with IPC Class 2/3 standards and testing protocols like flying probe or fixture-based electrical testing.

Production Capacity and Responsiveness

Evaluate operational metrics to ensure alignment with project timelines:

- On-time delivery rate exceeding 97% as an indicator of production discipline

- Average response time under 3 hours for engineering inquiries

- Minimum monthly output capacity supporting both prototype and pilot-run volumes

Cross-reference these indicators with verifiable transaction histories and customer reorder rates to assess service consistency.

Quality Assurance and Compliance

Prioritize suppliers demonstrating adherence to recognized quality systems such as ISO 9001. While not always explicitly stated, compliance with RoHS and REACH directives is standard practice for export-oriented manufacturers. Request evidence of internal QA procedures, including AOI, X-ray inspection for buried vias, and solderability testing for assembled units. For medical, automotive, or aerospace applications, confirm traceability practices and process control documentation.

What Are the Best Flex PCB Prototyping Suppliers?

| Company Name | Main Products | MOQ | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Verified Supplier |

|---|---|---|---|---|---|---|---|

| Toptek Pcb Co., Limited | Multilayer PCB, PCBA, Other PCB & PCBA | 1 piece | $0.80–1.20 | 100.0% | ≤2h | 66% | Yes |

| Shenzhen Yingsheng Technology Co., Ltd. | Rigid-Flex PCB, HDI PCB, Aluminum PCB, PCBA | 1–5 pieces | $2–5 | 100.0% | ≤8h | <15% | No |

| Pinsheng Electronics Co., Ltd. | Flex-Rigid PCBA, Rapid Prototyping PCB | 1–10 pieces | $1.54–5.33 | 100.0% | ≤3h | <15% | Yes |

| Shenzhen Linghangda Technology Co., Ltd. | Prototype PCB, Flexible PCB, PCBA | 1 piece | $0.30–1.00 | 100.0% | ≤9h | <15% | Yes |

Performance Analysis

Toptek Pcb Co., Limited stands out with a high reorder rate (66%) and consistent sub-2-hour response times, indicating strong customer retention and responsive engineering support. Its competitive pricing and 1-piece MOQ make it well-suited for early-stage prototyping. Pinsheng Electronics and Linghangda Technology also offer aggressive entry-level pricing and low MOQs, though lower reorder rates suggest potential gaps in post-sale support or scalability. Shenzhen Yingsheng Technology provides broader technical offerings—including HDI and aluminum substrates—but at higher price points, positioning it for more complex designs. All top-tier suppliers maintain 100% on-time delivery records, underscoring reliable production planning.

FAQs

How to verify flex PCB prototyping supplier reliability?

Cross-check claimed certifications with official audit records where available. Request sample reports from quality inspections (e.g., solder paste analysis, cross-section imaging). Analyze customer reviews focusing on accuracy of layer alignment, dimensional tolerance, and clarity of technical communication during DFM review.

What is the typical lead time for flex PCB prototypes?

Standard single- or double-sided flex PCBs can be delivered in 3–7 working days. Multilayer or rigid-flex configurations typically require 8–12 days. Expedited services may reduce this by 2–3 days at additional cost. Add 3–5 days for full PCBA depending on component availability.

Do suppliers support full turnkey PCBA for flex circuits?

Yes, many suppliers offer end-to-end services including component sourcing, BOM validation, SMT placement, reflow, and final functional testing. Confirm whether they manage long-lead or proprietary components and if counterfeit avoidance policies are documented.

Can I customize material thickness and bend zones?

Most suppliers allow full customization of copper weight (1/2 oz to 2 oz), dielectric thickness (25–75μm), and selective stiffener placement. Dynamic flex designs require clear definition of bend radius and cycle life expectations in the Gerber package.

Are there any hidden costs in low-MOQ orders?

While unit prices may appear low, additional fees can apply for engineering setup, film plotting, or small-panel surcharges. Clarify all charges upfront and request a detailed quote breakdown before order confirmation.