Flex Circuit Prototyping

CN

CN

CN

CN

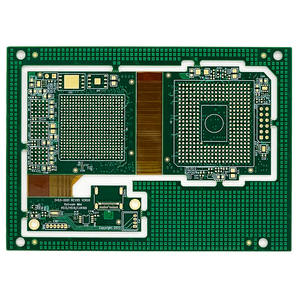

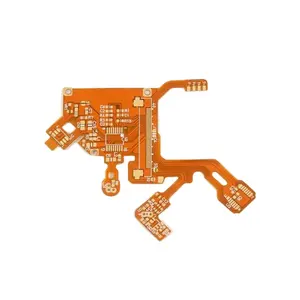

About flex circuit prototyping

Where to Find Flex Circuit Prototyping Suppliers?

China remains the global epicenter for flex circuit prototyping, with key manufacturing clusters in Shenzhen, Suzhou, and surrounding industrial zones offering integrated supply chains and rapid turnaround. Shenzhen alone accounts for over 40% of China’s flexible PCB production capacity, leveraging proximity to semiconductor suppliers and logistics hubs for accelerated prototyping cycles. These regions host vertically aligned facilities capable of handling design validation, material sourcing, fabrication, and assembly under one roof, enabling lead times as short as 3–5 days for single-layer prototypes.

The ecosystem supports both low-volume R&D batches and scalable pilot runs, with many suppliers operating automated SMT lines and impedance-controlled etching processes. Buyers benefit from localized access to polyimide films, adhesiveless copper laminates, and laser drilling equipment, reducing material procurement delays by up to 50%. Cost efficiency is further enhanced through shared tooling and panelization strategies, allowing prototype pricing from $0.21 per unit at small scale. This concentration enables faster iteration, with Gerber-to-board delivery averaging 7–10 days across most suppliers.

How to Choose Flex Circuit Prototyping Suppliers?

Procurement decisions should be guided by technical capability, quality assurance, and responsiveness metrics:

Design & Engineering Support

Verify supplier expertise in handling high-density interconnect (HDI) layouts, rigid-flex stackups, and impedance control. Look for evidence of in-house engineering teams capable of reviewing layout files, suggesting DFM improvements, and supporting reverse engineering or cloning services. Suppliers offering free design validation and 24-hour technical feedback demonstrate stronger process maturity.

Quality Management Systems

Prioritize partners with documented compliance to IPC-6013 (flexible circuit qualification) and ISO 9001 standards. RoHS and UL certification are critical for market-specific regulatory alignment. Confirm that final testing includes electrical continuity checks, solder mask adhesion tests, and thermal cycling validation—especially for dynamic flex applications.

Production Readiness & Transaction Metrics

Evaluate operational indicators such as response time, on-time delivery rate, and reorder frequency. Suppliers with sub-2-hour average response times and >95% on-time delivery rates typically maintain dedicated project management systems. Cross-check online transaction volume as a proxy for export experience—suppliers reporting over US $100,000 in annual revenue generally have established international shipping protocols and multilingual support.

What Are the Best Flex Circuit Prototyping Suppliers?

| Company Name | Location | Verified Type | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Min. Order | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Toptek Pcb Co., Limited | China | Multispecialty Supplier | 100% | 66% | ≤2h | US $1,000+ | 1 piece | Design, material, size, logo, packaging label |

| Shenzhen UC Industrail Limited | Shenzhen, CN | Multispecialty Supplier | 100% | 47% | ≤4h | US $170,000+ | 1 piece | Color, size, logo, material, Gerber file, firmware, reverse engineering |

| Suzhou Engine Electronic Technology Co., Ltd. | Suzhou, CN | Multispecialty Supplier | 91% | 15% | ≤3h | US $50,000+ | 1 piece | Color, size, logo, packaging label |

| Shenzhen Wanfeng Technology Co., Ltd. | Shenzhen, CN | - | 100% | 28% | ≤1h | US $1,400,000+ | 1 piece | Color, material, size, logo, packaging label, graphic |

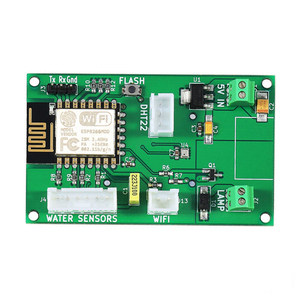

| King Field Electronic Co., Ltd. (shenzhen) | Shenzhen, CN | Custom Manufacturer | 95% | 32% | ≤2h | US $190,000+ | 1 piece | Pcb design, layers, finish (ENIG/HASL), material, Raspberry PI integration, BOM list, Wi-Fi mesh, complex boards |

Performance Analysis

Toptek Pcb and Shenzhen UC Industrial lead in reliability with perfect on-time delivery records and strong customization depth, including reverse engineering and firmware integration. Shenzhen Wanfeng stands out in transaction volume (US $1.4M+), indicating extensive export experience and robust fulfillment infrastructure, backed by the fastest average response time (≤1h). King Field Electronic offers the broadest technical scope, supporting advanced features like ENIG finishes, HDI designs, and IoT integrations, making it ideal for complex rigid-flex prototypes. While Suzhou Engine maintains competitive pricing and 1-piece MOQs, its lower reorder rate suggests potential gaps in post-sale support or consistency. Buyers requiring fast-turn, low-MOQ prototypes should prioritize suppliers with ≤2h response times and ≥95% delivery performance.

FAQs

How to verify flex circuit prototyping supplier reliability?

Cross-validate certifications (ISO, UL, RoHS) through official registries and request test reports for peel strength, bend cycle endurance, and dielectric performance. Analyze supplier tags for consistent on-time delivery (>95%) and reorder rates (>25%) as proxies for customer satisfaction. Video audits of production floors can confirm in-house capabilities versus outsourcing.

What is the typical prototype lead time?

Standard single- or double-sided flex circuits take 5–7 days from confirmed Gerber files. Rigid-flex or impedance-controlled designs may require 8–12 days. Rush services are available at select suppliers, reducing lead time to 3–4 days with expedited fees.

Do suppliers support 1-piece orders?

Yes, all listed suppliers offer 1-piece minimum order quantities, catering specifically to R&D and proof-of-concept stages. Pricing varies by complexity, with basic 2-layer prototypes starting at $0.30/unit and multi-layer rigid-flex boards exceeding $10/unit.

Can I submit my own Gerber files?

All suppliers accept Gerber, Excellon, and IPC-2581 files for fabrication. Most provide free DFM checks within 24 hours and will flag issues related to trace width, spacing, or layer alignment before production begins.

What customization options are available?

Common options include solder mask color, surface finish (HASL, ENIG, Immersion Silver), stiffener integration (FR4, polyimide), and component labeling. Advanced suppliers support functional customizations such as embedded components, antenna integration, and IoT module pairing based on BOM inputs.