All Flex Circuits

1/26

1/26

1/34

1/34

1/3

1/3

1/60

1/60

1/29

1/29

1/44

1/44

CN

CN

1/20

1/20

1/24

1/24

1/20

1/20

About all flex circuits

Where to Find All Flex Circuits Suppliers?

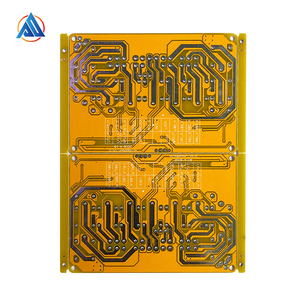

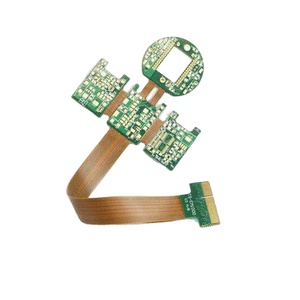

China remains the central hub for flexible printed circuit (FPC) manufacturing, with Shenzhen and Suzhou emerging as key industrial clusters due to concentrated expertise in electronics fabrication and supply chain integration. Shenzhen, a recognized leader in high-mix, low-volume electronics production, hosts advanced facilities specializing in rigid-flex, multi-layer FPCs, and custom flexible cable assemblies. The region benefits from proximity to semiconductor suppliers and contract manufacturers, enabling rapid prototyping and scalable production. Suzhou complements this ecosystem with strong capabilities in precision etching and thin-film technologies, supporting high-density interconnect (HDI) applications common in medical devices and aerospace systems.

These clusters offer vertically integrated production lines—from copper lamination and photolithography to automated optical inspection (AOI) and final assembly—reducing lead times by up to 25% compared to non-specialized regions. Buyers gain access to mature infrastructure where material sourcing, surface finishing (ENIG, immersion silver), and testing are performed in-house. Typical advantages include MOQ flexibility (as low as 1 piece), per-unit pricing starting below $0.10 at scale, and turnaround times of 5–15 days for samples depending on complexity. Export-ready compliance with IPC-6013 Class 2 standards is standard among established suppliers.

How to Choose All Flex Circuits Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

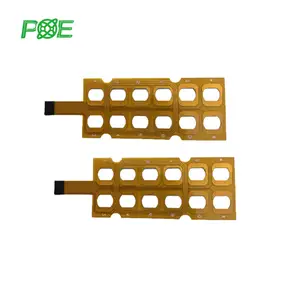

Confirm support for required stack-ups (single-sided, double-sided, multi-layer), materials (polyimide, PET), and thickness ranges (0.05–0.5mm). For dynamic flex applications, demand proof of bend cycle testing (e.g., 10,000+ cycles at 180°). Suppliers should offer impedance control, controlled depth routing, and laser drilling for micro-vias. Customization scope—including color masking, selective stiffeners, and ZIF tail configurations—must be clearly defined.

Production & Quality Assurance Audits

Assess core manufacturing parameters:

- In-house capabilities covering photolithography, etching, and SMT assembly

- Compliance with RoHS, REACH, and UL 94V-0 flammability standards

- Testing protocols: flying probe, ICT, and functional testing under thermal cycling

Prioritize suppliers with documented quality management systems (ISO 9001 preferred) and online revenue exceeding US $50,000, indicating consistent order volume and process maturity.

Procurement Risk Mitigation

Utilize secure payment terms such as escrow or milestone-based disbursements tied to production milestones. Evaluate response time (≤4 hours ideal) and on-time delivery performance (>95% recommended). Request sample batches before full-scale orders to validate dimensional accuracy, solder mask adhesion, and electrical continuity. Clarify packaging specifications (static shielding, humidity control) for sensitive shipments.

What Are the Best All Flex Circuits Suppliers?

| Company Name | Location | Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Pengda Circuit Co., Ltd. | Shenzhen, CN | Custom Manufacturer | Rigid-flex PCBs, FPCs, Flexible Cables | US $10,000+ | 100% | ≤4h | 66% | Color, material, size, logo, packaging, label, graphic |

| Suzhou Engine Electronic Technology Co., Ltd. | Suzhou, CN | Multispecialty Supplier | Rigid-Flex PCBs, FPC Cables | US $50,000+ | 92% | ≤3h | 16% | Color, size, logo, packaging, label |

| Shenzhen Yizexin Technology Co., Ltd. | Shenzhen, CN | OEM/ODM | FPCs, Keypads, Pressure Sensors | US $20,000+ | 100% | ≤3h | 33% | Not specified |

| Shenzhen E-Connecting Technology Co., Ltd. | Shenzhen, CN | OEM/ODM | FPCs, Wiring Harnesses, Connectors | US $120,000+ | 95% | ≤2h | 25% | Not specified |

| Shenzhen Run Zi Yang Electronics Company Limited | Shenzhen, CN | FPC Specialist | FPCs, Other PCB & PCBA | US $7,000+ | 100% | ≤9h | - | Not specified |

Performance Analysis

Shenzhen-based suppliers dominate responsiveness and delivery reliability, with three achieving 100% on-time fulfillment. Shenzhen E-Connecting leads in transaction volume (US $120,000+ online revenue), suggesting robust export capacity and customer acquisition. Suzhou Engine Electronics offers competitive pricing ($0.30–$0.50/unit) and fast response times despite a lower reorder rate, indicating potential for cost-sensitive projects requiring agility. Shenzhen Pengda stands out for broad customization options and strong repeat business (66% reorder rate), signaling high client satisfaction in tailored solutions. Buyers seeking complex rigid-flex designs should prioritize suppliers offering design-for-manufacturability (DFM) feedback and impedance modeling.

FAQs

What is the typical MOQ for all flex circuits?

Minimum order quantities vary by supplier and complexity. Standard single-layer FPCs can have MOQs as low as 1 piece, while multi-layer or impedance-controlled boards may require 5–100 pieces. High-volume producers often reduce per-unit costs significantly beyond 1,000 units.

How long does sampling take for custom flex circuits?

Sample lead times range from 5 to 12 days, depending on layer count and processing requirements. Rapid-turn services (3–5 days) are available from select suppliers for simple single- or double-sided circuits. Add 3–7 days for international express shipping.

Are flex circuit suppliers compliant with environmental standards?

Most established suppliers adhere to RoHS and REACH directives, using lead-free finishes and halogen-free materials upon request. Verify compliance through product declarations or material test reports (MTRs), especially for consumer electronics and medical applications.

Can suppliers handle full turnkey assembly?

Some manufacturers offer integrated FPC-to-assembly services, including component procurement, SMT placement, and testing. Confirm availability of pick-and-place machines, reflow ovens, and AOI systems. Turnkey pricing typically includes NRE tooling fees for small batches.

What file formats are required for FPC orders?

Standard submissions include Gerber files (RS-274X), NC drill files, and a Bill of Materials (BOM). For rigid-flex designs, 3D STEP models or detailed stack-up diagrams are recommended. Suppliers may provide DFM checks within 24–48 hours of submission.