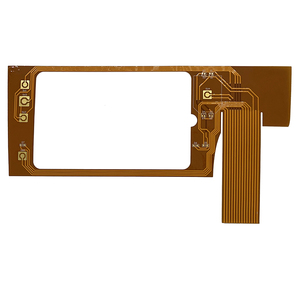

Minco Flex Circuits

CN

CN

CN

CN

About minco flex circuits

Where to Source Minco Flex Circuits Suppliers?

China remains a central hub for flexible circuit manufacturing, with key production clusters in Shenzhen and surrounding Guangdong regions driving innovation and cost efficiency. These zones host vertically integrated supply chains that streamline material sourcing—particularly polyimide films and copper laminates—and support rapid prototyping and high-volume output. Proximity to Tier-1 electronics OEMs enables suppliers to maintain agile production cycles, while established logistics networks facilitate global distribution with minimal delays.

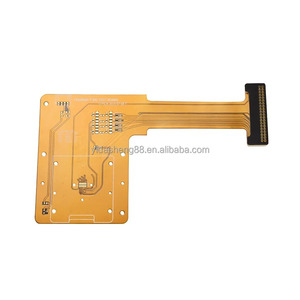

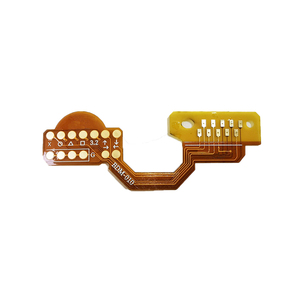

The ecosystem supports both standard and specialized flex circuit fabrication, including single-sided, double-sided, and rigid-flex configurations. Many manufacturers operate under cleanroom conditions and employ automated optical inspection (AOI) systems to ensure traceability and yield consistency. Buyers benefit from localized component availability, reduced tooling costs, and scalability—enabling lead times as short as 5–7 days for prototypes and 10–15 days for批量 orders. Cost advantages range from 20–40% compared to North American or European fabricators, particularly for low-to-mid volume runs.

How to Evaluate Minco Flex Circuits Suppliers?

Procurement decisions should be guided by technical capability, operational reliability, and quality assurance protocols:

Manufacturing & Technical Capacity

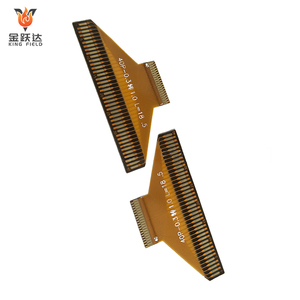

Confirm the supplier’s ability to produce required stack-ups, minimum trace widths/spacing (down to 75μm), and bend radii specifications. For rigid-flex designs, verify lamination process control and via reliability testing. Preferred suppliers maintain in-house capabilities for laser drilling, coverlay application, and impedance-controlled routing.

Quality Management Systems

Prioritize partners demonstrating compliance with IPC-6013 (flexible circuit qualification) and ISO 9001 standards. While not all suppliers list certifications explicitly, consistent on-time delivery (>95%) and reorder rates above 60% indicate stable quality and customer satisfaction. Request evidence of electrical testing (flying probe or bed-of-nails) and solderability validation.

Customization and Transaction Metrics

Assess responsiveness (target ≤4 hours), customization scope (material type, layer count, surface finish), and packaging flexibility. Analyze online transaction data where available—suppliers with higher reported revenues (e.g., US $10,000+) typically handle complex or recurring orders. MOQs are frequently set at 1 piece for samples, enabling low-risk evaluation prior to volume scaling.

What Are the Top Minco Flex Circuits Suppliers?

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Price Range (per piece) | Customization Options |

|---|---|---|---|---|---|---|---|

| Toptek Pcb Co., Limited | Rigid-flex PCB, FPC Assembly | 100% | 66% | ≤2h | US $1,000+ | $0.90–5.00 | Yes |

| Shenzhen Pengda Circuit Co., Ltd. | FPC, Rigid-Flex Board | 100% | 100% | ≤4h | US $10,000+ | $0.80–1.00 | Color, size, logo, packaging |

| Sunsoar Tech Co., Limited | FPC, Multilayer PCB, PCBA | 100% | 100% | ≤3h | US $10,000+ | $0.99–30.00 | Limited |

| Shenzhen Shenwin Electronic Co., Ltd. | Rigid-Flex PCB, FPC | 100% | - | ≤1h | US $100+ | $0.80–2.00 | Yes |

| Finest PCB Assemble Limited | Flexible PCB Prototype | 72% | <15% | ≤3h | US $9,000+ | $1.50–2.00 | Color, size, graphic |

Performance Analysis

Suppliers like Shenzhen Pengda Circuit and Sunsoar Tech demonstrate strong customer retention (100% reorder rate) and full on-time delivery performance, indicating robust internal processes. Toptek Pcb balances competitive pricing with solid repeat business metrics, while Shenzhen Shenwin leads in responsiveness (≤1h), making it suitable for urgent RFQs. Pengda and Finest PCB emphasize customization breadth, allowing buyers to tailor visual and functional attributes. However, Finest PCB’s low reorder rate (<15%) and suboptimal on-time delivery (72%) suggest potential fulfillment risks despite high revenue volume. For mission-critical applications, prioritize suppliers with proven track records in multilayer and rigid-flex fabrication, supported by responsive engineering teams.

FAQs

How to verify flex circuit supplier quality?

Cross-check production claims with response time, delivery performance, and transaction history. Request sample test reports including peel strength, thermal cycling results, and continuity checks. For long-term partnerships, conduct virtual audits to observe soldermask application, etching precision, and final AOI stages.

What is the typical lead time for flex circuit samples?

Standard flexible circuits can be produced in 5–7 days, while rigid-flex or HDI variants may require 10–14 days depending on layer count and lamination complexity. Expedited services are available from select suppliers for urgent development cycles.

Can suppliers accommodate small-batch custom orders?

Yes, most listed suppliers offer MOQs as low as 1 piece, particularly for prototypes. Unit costs decrease significantly at volumes exceeding 100 units, with scalable pricing models across 500–1,000+ unit tiers.

Do these suppliers support design-for-manufacturability (DFM) feedback?

Leading suppliers provide DFM analysis during quotation, identifying risks related to bend zones, via placement, and copper distribution. This service reduces rework and improves first-pass yield, especially for dynamic flex applications.

What materials are commonly used in Minco-style flex circuits?

Polyimide (PI) films such as Kapton are standard, paired with rolled or electrodeposited copper foils. Adhesive-based and adhesive-less laminates are available, with the latter preferred for enhanced thermal stability and flex endurance. Surface finishes include ENIG, Immersion Silver, and OSP.