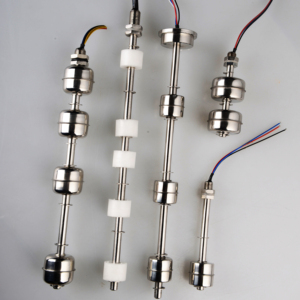

Float Sensor Wholesaler

Top sponsor listing

Top sponsor listing

1/55

1/55

1/51

1/51

1/6

1/6

1/39

1/39

1/19

1/19

1/35

1/35

1/2

1/2

1/28

1/28

1/12

1/12

About float sensor wholesaler

Where to Find Float Sensor Wholesalers?

China remains the central hub for float sensor manufacturing, with key production clusters in Guangdong, Shaanxi, and Jiangsu provinces. These regions host vertically integrated supply chains that support rapid prototyping and high-volume production of liquid level sensing solutions. Xi'an and Shenzhen are particularly notable for their concentration of electronic component manufacturers specializing in industrial sensors, offering buyers access to mature ecosystems combining R&D, precision molding, and automated assembly.

The industrial infrastructure enables efficient sourcing through localized material procurement—primarily stainless steel, polypropylene (PP), and ABS plastics—and streamlined logistics networks. Suppliers in these zones benefit from proximity to semiconductor foundries and electronic module producers, reducing component lead times by 20–30% compared to offshore alternatives. Buyers can expect standard order fulfillment within 15–30 days, depending on customization scope, with many wholesalers supporting drop-shipping and small-batch sampling.

How to Choose Float Sensor Wholesalers?

Selecting reliable partners requires due diligence across technical, operational, and transactional dimensions:

Product Compliance & Quality Assurance

Verify adherence to international standards such as CE, RoHS, and ISO 9001. For applications involving potable water or food-grade environments, confirm material certifications (e.g., NSF, WRAS). Request test reports for dielectric strength, temperature resistance, and cycle durability—especially for mechanical float switches subjected to continuous operation.

Manufacturing & Customization Capability

Assess supplier flexibility based on available customization parameters:

- Material options: Stainless steel (304/316), plastic (PP, PVC, ABS)

- Signal output types: On/off switch, analog (4–20mA, 0–5V), digital (I²C, UART)

- Mounting configurations: Top-mount, side-mount, cable-suspended

- Measurement range adjustability and multi-point detection support

Confirm in-house tooling and mold-making capacity for custom designs. Suppliers with dedicated R&D teams can typically deliver prototypes within 7–14 days.

Order & Logistics Performance

Analyze delivery consistency using verified metrics. Prioritize suppliers with on-time delivery rates exceeding 95%. Minimum Order Quantities (MOQs) vary significantly—from 1 piece for sample testing to 100–200 units for wholesale pricing. Evaluate response time (<7 hours preferred) and reorder rate (>20% indicates customer retention) as proxies for service reliability.

What Are the Leading Float Sensor Wholesalers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | MOQ Range | Customization Support | Verified Status |

|---|---|---|---|---|---|---|---|---|

| Xi'an Gavin Electronic Technology Co., Ltd. | Level Measuring Instruments, Pressure Sensors, Liquid Level Sensors | US $1,000,000+ | 98% | 18% | ≤2h | 100 pcs | Color, material, signal output, packaging, measurement range | Custom Manufacturer |

| Shenzhen Fast Sensor Co., Ltd. | Float Switches, Water Level Sensors | US $60,000+ | 88% | 20% | ≤7h | 100 pcs | Material, size, logo, packaging, temperature rating | Custom Manufacturer |

| La ceramica group srl | Liquid Level Sensors, Floating Ball Types | US $7,000+ | 100% | - | ≤9h | 1 pc | Limited data | Not specified |

| Wow Hvac Co., Ltd. | Liquid Level Sensors, Magnetic Sensors, HVAC Components | US $20,000+ | 100% | 15% | ≤9h | 1–2 pcs | Stainless steel variants, dual-point floats, connector types | Manufacturer |

| Guangzhou Lichi Technology Development Co., Ltd. | Fuel Level Sensors, Auto Sensors | US $160,000+ | 91% | 30% | ≤7h | 200 pcs | OEM fuel tank sensor replication, branding | Custom Manufacturer |

Performance Analysis

Xi'an Gavin leads in scale and responsiveness, with sub-2-hour replies and strong customization breadth, making it suitable for large-scale industrial deployments. Shenzhen Fast Sensor offers competitive pricing and solid reorder performance despite moderate delivery punctuality. Wow Hvac stands out for low MOQs and application-specific designs in HVAC systems, while Guangzhou Lichi excels in automotive-grade fuel level sensors with a high 30% reorder rate—indicating strong market fit. La ceramica group, though showing perfect on-time delivery, lacks reorder data and appears less specialized in core sensor production.

FAQs

What materials are commonly used in float sensors?

Stainless steel (304/316) is standard for corrosion-resistant industrial models. Plastics like PP, PVC, and ABS dominate low-cost consumer and residential applications. Seals typically use NBR or EPDM rubber for chemical compatibility.

What is the typical MOQ for float sensor wholesale orders?

MOQs range from 1 piece for sampling to 100–200 units for volume pricing. Some suppliers offer tiered pricing starting at 50 units. Automotive OEM replicas may require minimum batches of 500+ units.

Can float sensors be customized for specific voltage or signal output?

Yes, most manufacturers support custom signal conditioning circuits for 4–20mA, 0–10V, or relay outputs. Custom calibration for specific fluid densities and temperature ranges is also widely available upon request.

How long does sampling take?

Standard samples ship within 5–7 days. Customized units require 10–15 days depending on design complexity. Air freight adds 3–7 days for international delivery.

Do suppliers provide technical documentation?

Reputable wholesalers supply datasheets, wiring diagrams, installation guides, and compliance certificates. For integration into control systems, request output waveform specifications and IP rating validation reports.