Load Sensor Wholesaler

Top sponsor listing

Top sponsor listing

CN

CN

About load sensor wholesaler

Where to Find Load Sensor Wholesalers?

China remains the global epicenter for load sensor manufacturing, with key production hubs concentrated in Guangdong and Zhejiang provinces. Shenzhen and Ningbo serve as primary centers for precision transducer development, offering vertically integrated supply chains that support high-volume wholesale operations. These regions host specialized clusters focused on force measurement technologies, where suppliers leverage proximity to raw material sources, advanced machining facilities, and export logistics networks.

The industrial ecosystem enables streamlined production from design to delivery, with many wholesalers operating within 50km of component suppliers and testing laboratories. This integration supports competitive pricing—driven by localized sourcing of alloy steel, stainless steel, and aluminum strain gauge materials—and reduces lead times for both standard and customized sensors. Buyers benefit from scalable output, with select manufacturers reporting monthly online revenues exceeding US $400,000, indicating robust order-handling capacity.

How to Choose Load Sensor Wholesalers?

Effective supplier selection requires a structured evaluation of technical, operational, and transactional performance metrics:

Technical and Quality Compliance

Verify adherence to international quality standards such as ISO 9001, particularly for applications requiring long-term reliability in industrial weighing, automation, or medical devices. While explicit certification data is not provided, prioritize suppliers demonstrating consistent on-time delivery (≥96%) and low defect indicators through reorder rates below 15%. Confirm compatibility with full-bridge, half-bridge, or micro-load cell configurations based on application requirements.

Production and Customization Capability

Assess scalability and flexibility using available operational indicators:

- Suppliers with customization options offer modifications in size, material, color, logo, packaging, and labeling—critical for OEM integration

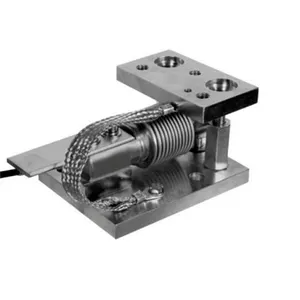

- Multiple product variants (e.g., S-type, beehive, pancake, and thin-film designs) indicate diversified tooling and engineering support

- Cross-reference response time (target ≤2 hours) and on-time delivery performance to gauge operational efficiency

Transaction Reliability and Risk Mitigation

Prioritize partners with verifiable performance histories, including documented on-time delivery rates above 95% and active online transaction volumes. Utilize secure payment mechanisms and request sample validation before bulk ordering. Evaluate minimum order quantities (MOQs), which range from 1 piece to 10 sets, to align with procurement scale and testing needs.

What Are the Best Load Sensor Wholesalers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Reorder Rate | Avg. Response Time | Online Revenue (USD) | Verified Type |

|---|---|---|---|---|---|---|---|

| Shenzhen ShengWanJiang Transducer Technology Co., Ltd. | Force Sensors & Load Cells | Yes | 100% | <15% | ≤1h | $8,000+ | Custom Manufacturer |

| Zhongshan Yipin Home Product Co., Ltd. | Baby Scales, Body Fat Scales, Force Sensors & Load Cells | No | 95% | <15% | ≤3h | $30,000+ | - |

| Locosc Ningbo Precision Technology Co., Ltd. | Load Cells, Weighing Systems, Junction Boxes | Yes | 96% | 33% | ≤3h | $100,000+ | Custom Manufacturer |

| Hanyu Electronic Technology Co., Ltd. | Micro Load Cells, S-Type, Beehive Sensors | Yes | 100% | <15% | ≤2h | $160,000+ | - |

| Shenzhen Tianzhongtian Trading Co., Ltd. | S-Type Load Cells (QLFS Series) | Yes | 93% | <15% | ≤3h | $400,000+ | Multispecialty Supplier |

Performance Analysis

Suppliers like Hanyu Electronic and Shenzhen ShengWanJiang demonstrate strong reliability with 100% on-time delivery and rapid response times, making them suitable for time-sensitive procurement. Hanyu stands out with the highest reported online revenue ($400,000+), suggesting extensive market reach and production volume. Locosc Ningbo offers customization across explosion-proof systems and junction boxes but has a higher reorder rate (33%), potentially indicating customer satisfaction challenges despite broad technical offerings. Shenzhen-based firms lead in responsiveness, with two suppliers answering inquiries within one hour, providing a strategic advantage for iterative design collaboration.

FAQs

What are typical MOQs for load sensor wholesalers?

Minimum order quantities vary significantly: some suppliers offer as low as 1 piece (e.g., micro-load cells), while others require 5–10 pieces per order, especially for high-capacity models (e.g., 50-ton load cells). Buyers should confirm MOQs based on sensor type and customization level.

How long do load sensor samples take to produce?

Standard samples can be shipped within 7–15 days, depending on complexity. Non-customized units are typically dispatched faster, while modified versions with specific calibration, labeling, or packaging may require up to 21 days.

Can load sensor suppliers handle global shipping?

Yes, all listed suppliers engage in international trade, evidenced by their online transaction activity. Confirm Incoterms (FOB, CIF) and coordinate with freight forwarders for customs clearance, particularly for regulated industrial electronics entering North America or EU markets.

Do wholesalers provide technical documentation?

Reputable suppliers supply datasheets, wiring diagrams, and calibration certificates upon request. For integration into larger systems (e.g., vending machines, human scales, truck scales), verify signal output (mV/V), accuracy class, and environmental protection ratings (IP65/IP67).

How to negotiate better pricing with load sensor suppliers?

Leverage volume commitments—suppliers often reduce unit costs significantly at 100+ unit tiers. Use competitive quotes from multiple vendors (e.g., comparing $0.22/unit at Zhongshan Yipin vs. $119.90/unit at Locosc for specialized models) to benchmark fair market value and negotiate tiered pricing structures.