Floating Picture Frames For Canvas

0

0

1/2

1/2

1/33

1/33

1/2

1/2

1/3

1/3

0

0

1/2

1/2

1/21

1/21

1/3

1/3

1/23

1/23

1/3

1/3

1/3

1/3

1/16

1/16

1/37

1/37

1/19

1/19

1/3

1/3

1/2

1/2

1/3

1/3

About floating picture frames for canvas

Where to Find Floating Picture Frames for Canvas Suppliers?

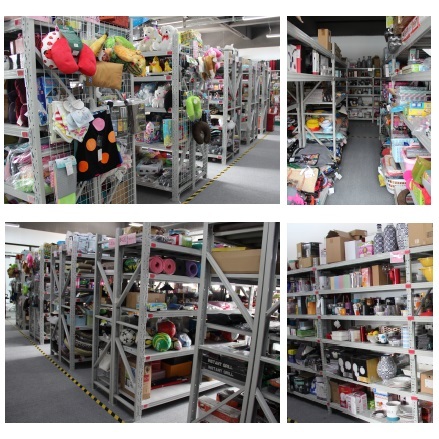

Manufacturing of floating picture frames for canvas is highly concentrated in China’s eastern coastal regions, particularly in Zhejiang and Guangdong provinces, where mature woodworking and metal fabrication ecosystems support high-precision finishing. These clusters offer vertically integrated production lines—from raw timber seasoning and MDF pressing to CNC milling, anodizing (for aluminum variants), and final assembly—enabling tight tolerances and consistent surface quality required for premium display applications.

Zhejiang excels in engineered wood and composite frame production, leveraging proximity to forestry resources and chemical treatment facilities that enhance moisture resistance. Guangdong, especially the Foshan and Dongguan zones, dominates aluminum-based floating frame manufacturing due to advanced extrusion capabilities and automated powder coating lines. The region's supply chain density reduces component procurement lead times by 25–40% compared to non-specialized industrial areas, supporting faster turnaround for both standard and custom profiles.

Suppliers in these hubs typically maintain monthly outputs ranging from 10,000 to 50,000 units, depending on material type and customization level. Economies of scale are further enhanced by shared logistics networks, with Ningbo and Shenzhen ports facilitating direct export routes to North America, Europe, and Oceania. Buyers benefit from shorter fulfillment cycles (average 25–35 days post-approval) and cost advantages, with per-unit pricing 18–30% below Western-made equivalents due to lower labor and overhead costs.

How to Choose Floating Picture Frames for Canvas Suppliers?

Implement rigorous evaluation criteria to ensure product consistency and compliance:

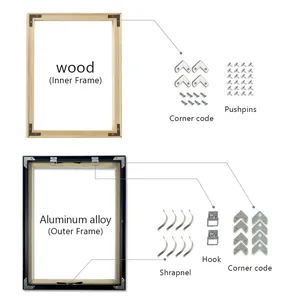

Material & Construction Standards

Confirm use of kiln-dried solid wood, MDF with formaldehyde emission ratings ≤0.05 ppm (CARB P2 compliant), or 6063-T5 aluminum alloy for structural integrity. For painted or stained finishes, require cross-cut adhesion testing (ISO 2409) and UV resistance reports (QUV accelerated aging ≥500 hours). Verify that spacer systems maintain a minimum 6mm gap between canvas and backing to allow for thermal expansion.

Production Capability Verification

Assess operational scale and technical readiness:

- Minimum 3,000m² factory area with dedicated CNC and finishing zones

- In-house tooling for custom profile design (e.g., beveled edges, shadow gaps)

- Certified joinery methods: mortise-and-tenon for wood, T-slot connectors for aluminum

Validate capacity via production logs and machine utilization rates; target suppliers with documented output stability across 3+ months.

Quality Management Systems

Require ISO 9001 certification as baseline process control. For EU-bound shipments, confirm RoHS and REACH compliance for paints and adhesives. Audit packaging protocols—frames should be individually wrapped in anti-scratch film and secured in double-wall cardboard with corner protectors to prevent transit damage. Request batch-specific QC checklists covering dimensional accuracy (±0.5mm tolerance), warpage (max 0.3° deviation over 1m length), and finish uniformity.

What Are the Best Floating Picture Frames for Canvas Suppliers?

No supplier data is currently available for this product category. Procurement professionals are advised to initiate targeted sourcing inquiries through verified B2B channels, prioritizing manufacturers with documented experience in art framing or museum-grade display solutions. Emphasis should be placed on suppliers demonstrating investment in precision equipment (e.g., CNC routers with ±0.1mm repeatability) and environmental controls (humidity-regulated drying rooms) to minimize warping risks.

Performance Analysis

In the absence of published performance metrics, due diligence must focus on technical documentation and sample validation. Prioritize partners offering comprehensive specification sheets, including material sourcing traceability, finish thickness (microns), and load-bearing test data for large-format frames (≥120cm sides). For integration into retail or gallery environments, verify compatibility with standard hanging systems (e.g., Z-bar, French cleat) and request installation guides. When evaluating new suppliers, conduct phased trials starting with small-batch orders to assess consistency before scaling.

FAQs

How to verify floating picture frame supplier reliability?

Request facility inspection reports, preferably third-party conducted (e.g., SGS, BV). Evaluate responsiveness to technical queries, consistency in sample quality, and clarity of contractual terms. Analyze customer references focusing on defect rates, packaging efficacy, and post-delivery support.

What is the average sampling timeline?

Standard samples take 7–12 days to produce, including finishing and curing. Custom profiles or specialty finishes (e.g., brushed brass, matte black epoxy) may extend to 18 days. Air freight adds 5–9 days depending on destination. Sample fees typically range from $50–$150 per unit, refundable against bulk orders exceeding MOQ.

Can suppliers ship floating picture frames worldwide?

Yes, experienced exporters manage global logistics via FOB, CIF, or DDP terms. Confirm Incoterms alignment and verify export licenses for wooden components subject to ISPM 15 regulations. Sea freight is optimal for full-container loads (20ft ≈ 8,000–12,000 units); LCL options suit trial shipments.

Do manufacturers provide free samples?

Free samples are uncommon unless tied to projected annual volumes exceeding 50,000 units. Most suppliers apply sample charges to deter speculative requests. Fee waivers may be negotiated upon confirmation of purchase intent and signed NDA.

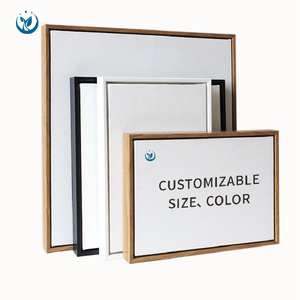

How to initiate customization requests?

Submit detailed specifications including internal dimensions, rabbet depth, frame width, material preference, and finish requirements. Provide CAD files or physical prototypes for complex designs. Reputable suppliers will respond with engineering drawings, material certifications, and tooling cost estimates within 5 business days.