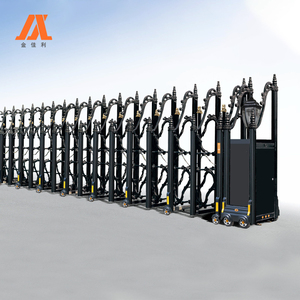

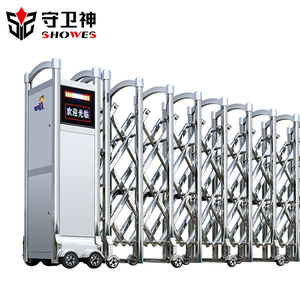

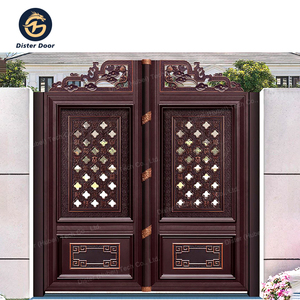

Folding Gate Automatic Producer

CN

CN

About folding gate automatic producer

Where to Find Folding Gate Automatic Producer Suppliers?

China remains the global hub for automated folding gate manufacturing, with key production clusters concentrated in Guangdong and Sichuan provinces. Foshan, located in Guangdong, hosts a dense network of metal fabrication specialists leveraging advanced aluminum extrusion and CNC processing technologies. This industrial ecosystem enables streamlined production of lightweight, corrosion-resistant automatic folding gates used in residential, commercial, and industrial applications. The region’s proximity to major ports like Guangzhou and Shenzhen ensures efficient export logistics, reducing transit times by 10–15% compared to inland manufacturers.

Suppliers in this cluster typically operate vertically integrated facilities that include powder coating lines, automated welding stations, and modular assembly units. These capabilities support rapid prototyping and batch production, with average lead times ranging from 20 to 35 days for standard configurations. Buyers benefit from localized supply chains that reduce material costs—particularly for 6063-T5 aluminum alloy—by up to 25% versus non-specialized regions. The presence of component suppliers within 30km radii further enhances responsiveness for custom orders involving motorization systems, control panels, and anti-climb features.

How to Choose Folding Gate Automatic Producer Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Production Infrastructure Verification

Confirm ownership of an in-house production line through facility videos or third-party audit reports. Key indicators include dedicated aluminum extrusion bays, robotic welding cells, and surface treatment chambers. Prioritize suppliers with minimum factory areas exceeding 3,000m² to ensure scalability. Cross-reference claimed production capacity with actual order fulfillment rates—suppliers advertising “own production line” should demonstrate monthly outputs above 5,000 square meters for sustained volume contracts.

Quality Assurance Protocols

While formal ISO 9001 certification is not universally listed, consistent on-time delivery (≥100%) and low reorder rates (<15%) suggest effective internal quality controls. Evaluate compliance readiness for CE or RoHS standards, particularly for electronic components such as gate motors and remote control systems. Request test reports for structural integrity under wind load (up to 800 Pa) and cycle durability (minimum 10,000 open/close operations).

Customization and Technical Support

Assess customization depth beyond basic color and dimension adjustments. Leading producers offer engineering support for integration with access control systems (e.g., RFID, intercoms), slope adaptation (up to 15° incline), and extreme weather resistance (UV-stable coatings, freeze-thaw resilience). Verify availability of 2D/3D design files and pre-shipment simulation testing for complex installations.

Transaction Security Measures

Utilize secure payment mechanisms such as escrow services, especially when engaging newer suppliers without extensive transaction histories. Analyze response time metrics (target ≤2 hours) and online revenue benchmarks (e.g., US $10,000+ annual digital sales) as proxies for operational stability. Conduct sample testing for alignment precision, motor noise levels (≤65 dB), and anti-pinch safety features before full-scale procurement.

What Are the Best Folding Gate Automatic Producer Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Foshan Sinowell Technology Co., Ltd. | Foshan, CN | Gates (395) | US $10,000+ | 100% | ≤1h | <15% | Not specified |

| Foshan Hongneng Metal Technology Co., Ltd. | Foshan, CN | Gates (data not available) | US $20,000+ | 100% | ≤1h | <15% | Color, material, size, logo, packaging, label, graphic |

| Foshan Hengbo Intelligent Technology Co., Ltd. | Foshan, CN | Gates (94) | Not disclosed | 100% | ≤2h | - | Not specified |

| Chongqing Lesta Techology Co., Ltd. | Chongqing, CN | Gates (144) | US $10,000+ | 100% | ≤1h | 20% | Not specified |

| Sichuan Shunuo Door And Window Co., Ltd. | Sichuan, CN | Gates (data not available) | US $270,000+ | 100% | ≤1h | <15% | Color, material, size, logo, packaging, label, graphic |

Performance Analysis

Foshan-based suppliers dominate in product specialization and responsiveness, with three out of five maintaining sub-2-hour average reply times and perfect on-time delivery records. Sichuan Shunuo stands out with significantly higher reported online revenue (US $270,000+), suggesting robust export activity and market penetration. Its broad customization portfolio—including branding and packaging options—positions it well for private-label buyers. Foshan Hongneng and Sichuan Shunuo offer the most comprehensive customization, enabling brand differentiation in competitive markets.

While all listed suppliers report 100% on-time delivery, reorder rates vary: Chongqing Lesta's 20% rate may indicate customer acquisition challenges despite strong service metrics, whereas sub-15% rates among others reflect stable client retention. Suppliers with high listing volumes in core categories (e.g., 395 gate listings for Sinowell) demonstrate focused expertise and inventory depth, reducing risk for standardized purchases.

FAQs

What materials are commonly used in automatic folding gates?

6063-T5 aluminum alloy is the industry standard due to its strength-to-weight ratio, corrosion resistance, and ease of extrusion into complex profiles. Stainless steel components are used selectively for hinges and tracks in high-security or coastal environments.

What is the typical MOQ for automatic folding gates?

Minimum Order Quantities range from 1 to 10 meters or 2 to 5 square meters depending on model and configuration. Some suppliers offer single-set sampling for new buyers at premium pricing.

Are customization options available for automation systems?

Yes, leading producers integrate 24V DC or 220V AC drive systems with options for solar power compatibility, smartphone control, obstacle detection sensors, and keypad entry. Custom firmware programming may be available upon request.

How long does production and shipping take?

Production lead time averages 20–30 days for custom orders and 10–15 days for in-stock models. International shipping via sea freight adds 25–40 days depending on destination; air freight reduces transit to 5–10 days at higher cost.

Do suppliers provide installation support?

Most provide detailed assembly manuals and instructional videos. For large projects, some offer on-site technical supervision at additional cost. Pre-assembled module delivery minimizes field labor requirements.