Formwork For Circular Columns Factory

CN

CN

CN

CN

CN

CN

CN

CN

About formwork for circular columns factory

Where to Find Formwork for Circular Columns Suppliers?

China leads global production of formwork systems for circular columns, with key manufacturing clusters in Henan, Tianjin, and Guangdong provinces. These regions host vertically integrated factories specializing in plastic, steel, plywood, and composite material formwork solutions. Zhengzhou (Henan) and Tianjin are central hubs for large-scale industrial output, supported by mature supply chains for raw materials like PP, PVC, ABS, and galvanized steel. Guangzhou-based manufacturers focus on customized modular systems with rapid prototyping capabilities.

The concentration of specialized producers enables economies of scale, reducing unit costs and lead times. Factories in these zones typically operate dedicated production lines for circular column formwork, ensuring consistent dimensional accuracy and structural integrity. Buyers benefit from proximity to logistics centers—Zhengzhou’s rail infrastructure and Tianjin’s port facilities enable efficient export operations. Average lead times range from 15–30 days for standard orders, with localized sourcing cutting transportation costs by up to 25% compared to offshore alternatives.

How to Choose Formwork for Circular Columns Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Material & Design Capabilities

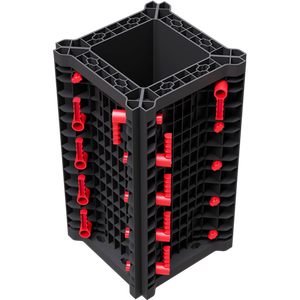

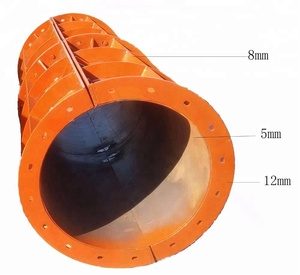

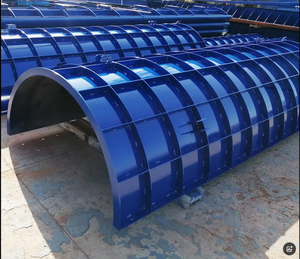

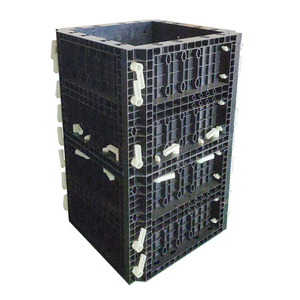

Confirm supplier expertise in core materials: plastic (PP/PVC/ABS), steel-reinforced composites, or film-faced plywood. Evaluate design flexibility—top-tier manufacturers offer adjustable diameters (300–1200mm), variable heights (up to 4m), and interlocking mechanisms for seamless assembly. Request engineering drawings, load-bearing calculations, and wall thickness specifications to validate performance under concrete pressure.

Production Infrastructure Verification

Assess factory capabilities through verifiable metrics:

- Ownership of in-house molding, extrusion, or CNC fabrication lines

- Monthly production capacity exceeding 10,000 units or 5,000+ square meters

- Dedicated quality control stations with waterproofing, compression, and durability testing

Cross-reference online revenue data and reorder rates as proxies for market trust and operational stability.

Quality Assurance & Compliance

While explicit ISO certification is not always listed, prioritize suppliers demonstrating adherence to international standards via product testing reports. Verify resistance to corrosion, UV degradation (for outdoor use), and concrete adhesion properties. For projects in regulated markets, confirm compatibility with local building codes and availability of third-party inspection documentation.

What Are the Best Formwork for Circular Columns Suppliers?

| Company Name | Location | Main Materials | Customization Options | Min. Order Quantity | On-Time Delivery | Avg. Response | Reorder Rate | Annual Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Songmao Building Materials Co., Ltd. | Henan, CN | Plastic, Plywood, Steel | Yes (diameter, height, layout, logo) | 1–100 pieces | 100% | ≤2h | 20% | US $1.4M+ |

| Tianjin Taishouxing International Co., Ltd. | Tianjin, CN | Steel | Limited | 200–500 pcs / 300 m² | 100% | ≤2h | 33% | US $2.8M+ |

| Hubei ADTO Aluminum Formwork Manufacturing Co., Ltd. | Hubei, CN | Plastic, Plywood, Aluminum | Moderate | 2–1000 pcs / 2–100 m² | 100% | ≤3h | 16% | US $410K+ |

| Guangzhou AJ Building Material Co.,Ltd | Guangdong, CN | Steel, Solid Wood, Composite | High (thermal break, clamps, size) | 200–300 pieces | 98% | ≤3h | 20% | US $1.3M+ |

| Hebei Mortmain Rubber And Plastic Technology Co., Ltd. | Hebei, CN | PVC, PP, Plastic Board | Basic (size, color) | 200–400 pieces | 100% | ≤5h | 33% | US $4K+ |

Performance Analysis

Tianjin Taishouxing and Hebei Mortmain exhibit high reorder rates (33%), indicating strong customer retention despite limited customization—ideal for buyers seeking standardized steel or plastic formwork at volume. Zhengzhou Songmao stands out for low MOQs (down to 1 piece) and broad material diversity, making it suitable for small projects or trial orders. Guangzhou AJ offers advanced customization, including thermal breaks and clamp systems, though its slightly lower on-time delivery rate (98%) warrants closer shipment monitoring. Hubei ADTO provides premium plywood and aluminum solutions but has a relatively lower reorder rate, suggesting room for service improvement.

FAQs

What materials are commonly used in circular column formwork?

The most prevalent materials include polypropylene (PP), polyvinyl chloride (PVC), acrylonitrile butadiene styrene (ABS), galvanized steel, and film-faced plywood. Each offers distinct advantages: plastics provide lightweight reusability, steel ensures high load-bearing capacity, and plywood allows cost-effective single-use applications.

What is the typical minimum order quantity (MOQ)?

MOQ varies significantly by material and supplier. Plastic and modular systems often require only 2–100 pieces, while steel and large-panel formwork may mandate 200–500 units or 300+ square meters. Some manufacturers offer sample orders starting at 1 piece for evaluation purposes.

Can suppliers customize formwork dimensions and features?

Yes, many suppliers support tailored diameters (e.g., 300–1200mm), adjustable heights, interlocking edges, bracing integration, and branding (logo printing). Custom tooling may incur additional setup fees and extended lead times, particularly for injection-molded plastic variants.

How long does production and shipping take?

Standard production lead time ranges from 15 to 25 days after order confirmation. Air freight delivers samples within 7–10 days; sea freight for bulk orders takes 20–35 days depending on destination. Expedited production (7–10 days) is available from select manufacturers for urgent needs.

Are there quality control measures in place?

Top suppliers implement pre-shipment inspections, including dimensional checks, compression tests, and surface finish verification. Buyers are advised to request test reports or video audits of production processes. Third-party inspection services can be arranged prior to shipment for added assurance.