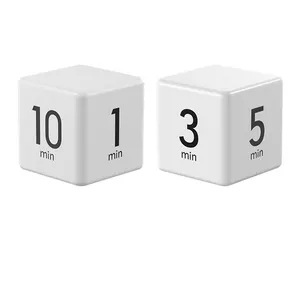

Free Count Down Timers

0

0

1/3

1/3

1/3

1/3

1/15

1/15

1/29

1/29

1/14

1/14

1/5

1/5

1/3

1/3

1/3

1/3

1/20

1/20

1/3

1/3

1/14

1/14

1/3

1/3

1/11

1/11

1/2

1/2

About free count down timers

Where to Find Free Count Down Timers Suppliers?

Global sourcing for free count down timers is primarily concentrated in manufacturing hubs across South China, particularly Guangdong and Zhejiang provinces, where electronics and consumer device production is highly centralized. These regions host extensive supply chains integrating plastic molding, electronic component assembly, and digital display fabrication, enabling cost-efficient production of both basic and feature-enhanced models. Dongguan and Shenzhen in Guangdong province account for over 70% of small electronic timer manufacturing, supported by proximity to semiconductor suppliers and automated SMT (Surface Mount Technology) lines.

Vertical integration within these clusters allows suppliers to streamline production from PCB printing to final packaging, reducing unit costs by 25-40% compared to non-specialized manufacturers. Buyers benefit from rapid prototyping capabilities—typically 7–10 days for sample development—and scalable output, with leading facilities capable of monthly volumes exceeding 500,000 units. Logistics infrastructure further enhances efficiency, with Shenzhen’s port and airport facilitating air and sea freight options for global distribution within 15–30 days.

How to Choose Free Count Down Timers Suppliers?

Implement structured evaluation criteria to ensure product quality, compliance, and operational reliability:

Technical Compliance

Verify adherence to international safety and environmental standards. Essential certifications include CE (EMC and LVD directives), RoHS for hazardous substance restrictions, and FCC Part 15 for electromagnetic compatibility in North American markets. Request test reports from accredited laboratories confirming electrical safety, battery leakage resistance (if applicable), and display durability under continuous operation.

Production Capability Audits

Assess supplier infrastructure through documented evidence:

- Minimum 2,000m² production area with dedicated clean zones for PCB assembly

- In-house capabilities in injection molding, PCB soldering, and firmware programming

- Automated testing stations for functional verification (button response, timing accuracy, alarm consistency)

Confirm monthly output capacity aligned with order volume; suppliers serving bulk institutional orders (schools, hospitals) should demonstrate ≥100,000 units/month throughput.

Transaction Safeguards

Utilize secure payment methods such as third-party escrow or letter of credit for initial large-volume orders. Prioritize suppliers with verifiable export histories to your target market, especially those experienced in meeting labeling, language, and packaging requirements for EU, US, or ANZAC regions. Conduct pre-shipment inspections via third-party QA firms to validate functionality across a statistically significant sample size (AQL Level II).

What Are the Best Free Count Down Timers Suppliers?

No supplier data is currently available for free count down timers.

Performance Analysis

In the absence of verified supplier profiles, procurement teams should focus on identifying manufacturers with proven experience in similar electronic timekeeping devices—such as kitchen timers, classroom aids, or medical interval trackers. Emphasis should be placed on firms offering customizable firmware (e.g., preset intervals, sound profiles, backlight colors) and flexible MOQs (as low as 500 units for trial orders). Video audits of production lines can help confirm automation levels and quality control checkpoints, particularly at burn-in testing stages where timers undergo 24+ hours of continuous operation validation.

FAQs

How to verify free count down timers supplier reliability?

Cross-validate business licenses and certification authenticity through official registries. Request references from existing clients in education, healthcare, or retail sectors. Review audit trails including material traceability records, incoming QC logs, and final inspection checklists. Use independent inspection services to assess factory conditions and workmanship quality.

What is the average sampling timeline?

Standard sample production takes 7–12 days, depending on customization level. For units requiring custom molds or unique casing designs, lead times extend to 18–25 days. Air shipping adds 5–8 days for international delivery. Expedited service (3–5 days) may be available at a premium.

Can suppliers ship free count down timers worldwide?

Yes, most established suppliers support global shipping via DDP (Delivered Duty Paid) or FOB terms. Confirm compliance with destination regulations regarding lithium battery shipments (if applicable) and electronic labeling. Sea freight is optimal for container loads (>50,000 units), while express courier services suit smaller batches.

Do manufacturers provide free samples?

Sample policies vary. Many suppliers offer one complimentary sample per inquiry if future volume potential is demonstrated. For customized versions, expect to cover full production and tooling costs initially, which may be reimbursed upon order confirmation above specified thresholds (e.g., 5,000 units).

How to initiate customization requests?

Submit detailed technical specifications including dimensions, power source (battery type or USB-powered), countdown range (1 min to 999 min), display type (LCD, LED, OLED), and desired features (repeating cycle, silent mode, pause/resume). Reputable suppliers will respond with schematic drafts or 3D renderings within 48–72 hours and deliver functional prototypes within 2–3 weeks.