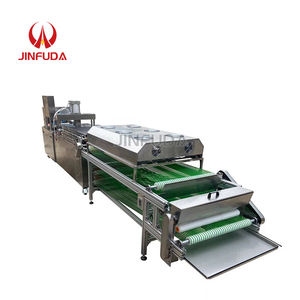

Fully Automatic Chapati Making Machine Price

1/3

1/3

1/7

1/7

1/14

1/14

1/12

1/12

1/4

1/4

About fully automatic chapati making machine price

Where to Find Fully Automatic Chapati Making Machine Suppliers?

China remains the dominant hub for fully automatic chapati making machine manufacturing, with key production clusters in Henan, Shandong, and Jiangsu provinces. These regions host vertically integrated supply chains encompassing sheet metal fabrication, precision machining, and food-grade assembly lines, enabling cost-efficient production at scale. Henan, in particular, has emerged as a center for grain product machinery, hosting over 40% of China’s commercial flatbread equipment manufacturers. Proximity to raw material sources—such as stainless steel and industrial motors—reduces component costs by 15–25% compared to non-specialized regions.

The industrial ecosystems in these zones support rapid prototyping and high-volume output, with many suppliers operating facilities exceeding 3,000m² and maintaining in-house R&D teams focused on dough handling mechanics and thermal control systems. Buyers benefit from consolidated logistics networks that enable standard order fulfillment within 20–35 days. The concentration of technical talent and tier-one subcontractors within 50km radii ensures consistent quality control and agility in custom engineering, particularly for multi-language HMI interfaces or voltage-specific configurations (110V/220V).

How to Choose Fully Automatic Chapati Making Machine Suppliers?

Procurement decisions should be guided by structured evaluation criteria to mitigate operational and compliance risks:

Technical and Food Safety Compliance

Confirm adherence to ISO 9001 standards as a baseline for quality management. For export to regulated markets (EU, North America, GCC), verify CE marking or equivalent certifications ensuring electrical safety and hygienic design. Machines must utilize food-grade stainless steel (minimum SS304) in contact zones and comply with temperature control accuracy within ±5°C during continuous operation.

Production Capacity Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Factory area ≥3,000m² to support batch production

- In-house capabilities in CNC cutting, welding, and automated assembly

- Dedicated testing lines simulating real-time dough feeding, rolling, and baking cycles

Cross-reference declared capacity with online transaction volume and on-time delivery rates (>97% recommended).

Transaction and Quality Assurance Protocols

Utilize secure payment mechanisms such as escrow services to align financial release with shipment milestones. Prioritize suppliers offering sample validation under actual load conditions. Pre-shipment inspections should include verification of motor durability (rated for 8,000+ hourly cycles), uniform heat distribution across hot plates, and consistency in chapati thickness (adjustable range: 1.5–4mm). Request video audits of production lines to confirm process transparency.

What Are the Best Fully Automatic Chapati Making Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Jiaozuo Taoding Trading Co., Ltd. | Henan, CN | Grain Product Making Machines, Customizable Chapati Lines | $550,000+ | 97% | ≤2h | <15% | $550–$11,800 | 1 set |

| Jinan Star Bake Machinery Equipment Co., Ltd. | Shandong, CN | Commercial Chapati/Pita Systems, Dough Sheeters | $310,000+ | 100% | ≤7h | 20% | $1,850–$9,500 | 1 set |

| Henan Chuang Qin Mechanical Equipment Co., Ltd. | Henan, CN | Multi-Function Flatbread Makers, Samosa Sheet Units | $120,000+ | 100% | ≤2h | <15% | $600–$3,650 | 1 piece |

| Yangzhou Nuodi Machinery Co., Ltd. | Jiangsu, CN | Automatic Roti & Tortilla Systems | $5,000+ | 100% | ≤18h | <15% | $1,100–$2,000 | 1 set |

| Hnrb Foods Co., Ltd. | Henan, CN | Stainless Steel Chapati & Naan Machines | $20,000+ | 100% | ≤1h | 22% | $499–$1,500 | 1 set |

Performance Analysis

Jiaozuo Taoding offers the broadest price segmentation and customization depth, supporting diverse market needs—from budget units to high-capacity commercial systems. Jinan Star Bake distinguishes itself with premium-tier engineering, reflected in higher pricing and robust build quality suitable for 24/7 operations. Henan-based suppliers dominate responsiveness, with three providers achieving sub-2-hour average reply times, enhancing communication efficiency during technical negotiations. Hnrb Foods presents the most competitive entry-level pricing ($499), ideal for small-scale buyers, though with limited reorder frequency data. Suppliers with transaction volumes exceeding $100,000 demonstrate proven export experience and logistical reliability, particularly for Middle Eastern and South Asian markets where chapati demand is highest.

FAQs

What is the typical MOQ for fully automatic chapati machines?

Most suppliers list a minimum order quantity of 1 set or piece, facilitating low-risk procurement for startups and pilot deployments. Bulk discounts typically apply at 5+ units, with negotiable pricing based on configuration complexity.

How long does production and shipping take?

Lead time averages 20–30 days for standard models after deposit confirmation. Air freight requires 5–10 days for international delivery; sea freight takes 25–40 days depending on destination port. Expedited production (12–18 days) may be available upon request.

Can suppliers customize machine specifications?

Yes, leading manufacturers support customization of power voltage (110V/220V/380V), output capacity (600–1,800 pieces/hour), dough thickness settings, and branding (logo imprinting). Some offer modular upgrades for paratha lamination or frozen dough compatibility.

Do suppliers provide after-sales technical support?

Most offer remote troubleshooting via video guidance or manuals in multiple languages (English, Arabic, Hindi). Warranty periods range from 12 to 24 months, covering core components like heating elements and drive motors. Spare parts kits are often included with initial shipments.

Are samples available before bulk ordering?

Sample availability varies. Some suppliers offer functional samples at full price, which can be credited toward future orders. Others require sample fees covering material and labor, typically refundable upon contract signing. Testing samples under operational conditions is strongly advised to assess consistency and durability.