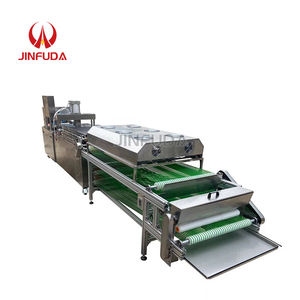

Fully Automatic Chapati Making Machine Price In India

1/21

1/21

1/12

1/12

1/4

1/4

1/12

1/12

1/3

1/3

About fully automatic chapati making machine price in india

Where to Find Fully Automatic Chapati Making Machine Suppliers?

India’s growing demand for industrial-scale food processing equipment has led to a surge in manufacturing and export activity, particularly in the fully automatic chapati making machine segment. Key production clusters are concentrated in Gujarat, Rajasthan, and Uttar Pradesh, where established metalworking and electrical engineering ecosystems support rapid prototyping and scalable output. These regions offer integrated supply chains for stainless steel fabrication, motor assembly, and control system integration—reducing component lead times by 20–30% compared to isolated workshops.

Suppliers leverage localized networks of sheet metal suppliers, CNC fabricators, and automation engineers within 30–50km radii, enabling end-to-end production under single facilities. This vertical integration supports batch outputs of 50–200 units per month per manufacturer, with standard delivery windows ranging from 15 to 45 days depending on order complexity. Buyers benefit from competitive pricing due to lower labor costs and domestic sourcing of core materials like SUS304 stainless steel and food-grade non-stick coatings.

How to Choose Fully Automatic Chapati Making Machine Suppliers?

Procurement decisions should be guided by systematic evaluation of technical, operational, and transactional criteria:

Technical Compliance & Design Validation

Confirm adherence to international electrical safety standards (IEC 60204) and food contact material regulations. While formal certifications such as CE or ISO 9001 are not universally present among Indian suppliers, request documentation for motor efficiency ratings (typically 220V/50Hz or dual-voltage 110V/220V), temperature control accuracy (±5°C), and dough handling mechanisms. Verify that rollers and pressing plates are constructed from food-grade stainless steel with anti-adhesive surface treatments.

Production Capacity Assessment

Evaluate supplier infrastructure through available metrics:

- Minimum factory area exceeding 1,000m² for consistent volume output

- In-house capabilities in sheet metal forming, welding, PLC programming, and final assembly

- Dedicated testing lines simulating continuous operation (e.g., 8–12 hour endurance runs)

- Monthly production capacity above 100 units for reliable scalability

Cross-reference listed response times and on-time delivery rates—suppliers with ≤3-hour average responses and verified 100% on-time performance demonstrate stronger operational discipline.

Transaction Risk Mitigation

Utilize secure payment frameworks such as escrow services or milestone-based disbursements tied to production progress. Prioritize suppliers offering sample units for field testing prior to bulk orders. Analyze reorder rates as an indicator of post-sale satisfaction; rates above 15% suggest acceptable product reliability and service responsiveness. Request video walkthroughs of assembly processes to validate claims about automation level and build quality.

What Are the Best Fully Automatic Chapati Making Machine Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order Quantity | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| GIRNAR MACHINE PRIVATE LIMITED | Grain Product Making Machines | $15 – $7,358 | 5 pcs / 1 box | Not specified | ≤25h | Not specified | Not specified | None listed |

| LEENOVA KITCHEN EQUIPMENTS PRIVATE LIMITED | Other Food Processing Machinery, Commercial Kitchen Equipment | $850 – $3,390 | 1 unit | Not specified | ≤5h | Not specified | Not specified | None listed |

| Hnrb Foods Co., Ltd. | Grain Product Making Machines, Vegetable Cutter, Snack Machines | $499 – $1,500 | 1 set | 100% | ≤1h | 19% | US $20,000+ | Color, material, size, logo, packaging, dough thickness, label, graphic |

| Zhengzhou Imaker Machinery Co., Ltd. | Other Snack Machines, Grain Product Making Machines, Meat Slicers | $890 – $9,900 | 1 set | 100% | ≤2h | <15% | US $60,000+ | None listed |

| Henan Penghui Machinery And Equipment Co., Ltd. | Customized Food Processing Equipment | $1,280 – $6,200 | 1 set | 100% | ≤3h | <15% | US $340,000+ | Color, material, size, logo, packaging, dough thickness, label, graphic |

Performance Analysis

Hnrb Foods Co., Ltd. stands out with a documented 100% on-time delivery rate, sub-1-hour response time, and a 19% reorder rate—indicating strong customer retention despite mid-range pricing. The company also offers extensive customization across mechanical, aesthetic, and branding parameters, making it suitable for buyers requiring private-label or application-specific configurations. Henan Penghui leads in online transaction volume (US $340,000+), reflecting high market engagement and export experience, while maintaining full punctuality and responsive communication. Zhengzhou Imaker presents a broad price spectrum, suggesting flexibility in configuration—from compact models at $890 to high-capacity systems exceeding $9,000. GIRNAR MACHINE PRIVATE LIMITED lists extreme price variance ($15 to $7,358), which may reflect listing inconsistencies or divergent product tiers, warranting direct clarification before procurement.

FAQs

What is the typical MOQ for fully automatic chapati making machines?

Minimum order quantities vary significantly: some suppliers require only 1 unit or set, while others mandate container-load batches (e.g., 1 box). For small-scale buyers or pilot testing, units priced between $499 and $3,390 often allow single-set purchases.

What are common lead times after order confirmation?

Standard lead times range from 15 to 30 days for ready-to-ship models. Customized units with specific voltage, dimension, or throughput requirements may extend to 45 days, especially if new tooling or control programming is required.

Can suppliers customize machine specifications?

Yes, select manufacturers—including Hnrb Foods Co., Ltd. and Henan Penghui Machinery—offer comprehensive customization options such as roller diameter, output speed (up to 2,000 rotis/hour), power supply compatibility, footprint dimensions, and branding elements like logos and color schemes.

Do these machines support different dough types?

High-end models are engineered to process wheat, millet, and multigrain doughs with adjustable thickness settings (typically 1.5–4mm). Ensure the supplier specifies compatibility with regional flour blends and hydration levels used in your target market.

How are shipments handled for international buyers?

Most suppliers accommodate FOB or CIF shipping terms. Machines are typically crated in wooden cases for sea freight, with air shipment options available for samples or urgent deliveries. Confirm inclusion of export documentation, including packing lists, commercial invoices, and certificates of origin.