Fully Automatic Papad Making Machine Price In India

About fully automatic papad making machine price in india

Where to Find Fully Automatic Papad Making Machine Suppliers?

China remains the primary global manufacturing hub for fully automatic papad making machines, with key supplier clusters concentrated in Shandong and Henan provinces. These regions host vertically integrated production ecosystems that combine food processing engineering expertise with advanced automation capabilities. Shandong's machinery corridor, centered around Jinan and Qingdao, specializes in snack food processing lines tailored for Indian market specifications, including 3D pellet extrusion and high-speed drying integration. Henan’s Zhengzhou zone focuses on cost-optimized packaging and forming systems, leveraging proximity to steel and control system component suppliers to reduce lead times by up to 25%.

Suppliers in these industrial zones operate facilities ranging from 4,000 to over 24,000 m², supporting batch production of complete turnkey lines. The regional supply chain enables rapid sourcing of critical subsystems—such as PLC-controlled feeding mechanisms, infrared drying tunnels, and stainless-steel rolling assemblies—within localized vendor networks. Buyers benefit from scalable output capacity, with standard machine delivery timelines averaging 30–45 days for single-unit orders and 60 days for full production lines. Average unit pricing reflects tiered segmentation: entry-level semi-automatic models start at $3,000, while fully integrated, high-throughput systems exceed $500,000 for customized configurations.

How to Choose Fully Automatic Papad Making Machine Suppliers?

Procurement decisions should be guided by structured evaluation criteria focused on technical capability, quality assurance, and transactional reliability:

Technical Compliance and Design Validation

Confirm adherence to international food safety standards, including CE marking for electrical systems and ISO 9001-certified quality management processes. Machines must utilize food-grade stainless steel (minimum SS304) for all product-contact surfaces and incorporate IP65-rated enclosures for motor and control units. Request detailed schematics covering automation architecture—specifically PLC brand (e.g., Siemens, Delta), HMI interface type, and energy consumption metrics (kW/h per 100 kg output).

Production Capacity and Infrastructure Audit

Evaluate supplier operational scale through verifiable benchmarks:

- Factory area exceeding 5,000 m² indicating volume production capability

- In-house R&D teams with documented experience in snack extrusion dynamics

- Integrated testing floors capable of dry-run demonstrations under simulated operating conditions

Cross-reference declared on-time delivery rates (target ≥97%) with historical performance data. Prioritize suppliers offering video audits of assembly lines and live operational footage.

Customization and After-Sales Support

Verify customization scope for mold dimensions, thickness control (0.8–4 mm range), hourly output (50–500 kg/h), and voltage compatibility (380V/50Hz standard for India). Demand inclusion of commissioning support, operator training, and spare parts kits (minimum one-year supply). Analyze reorder rates as a proxy for customer satisfaction—suppliers with rates above 30% demonstrate consistent post-delivery service performance.

What Are the Best Fully Automatic Papad Making Machine Suppliers?

| Company Name | Location | Online Revenue | Main Product Focus | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Quanzhou Ruiguang Machine Manufactory Co., Ltd. | Fujian, CN | Not disclosed | Paper & hygiene product machinery | 100% | ≤3h | Undisclosed | $232,000 – $500,000 |

| Shandong Aida Machinery Co., Ltd. | Shandong, CN | US $40,000+ | Snack & grain processing lines | 100% | ≤2h | <15% | $14,800 – $19,800 |

| Zhengzhou Yugong Construction Machinery Co., Ltd. | Henan, CN | US $810,000+ | Paper cup & packaging systems | 100% | ≤2h | 34% | $7,300 – $8,900 |

| Wenzhou Tianyue Machinery Co., Ltd. | Zhejiang, CN | US $650,000+ | Paper tableware & automation | 94% | ≤4h | 28% | $3,000 – $16,000 |

| Shandong Forward Machinery Co., Ltd. | Shandong, CN | US $10,000+ | Snack pellet & feed lines | 100% | ≤3h | 100% | $8,000 – $20,000 |

Performance Analysis

High-end suppliers like Quanzhou Ruiguang target premium export contracts with capital-intensive solutions priced above $230,000, likely reflecting full-line integration with frying, drying, and packing modules. In contrast, Shandong-based manufacturers offer economically scaled alternatives optimized for SME adoption in India, with competitive pricing between $8,000 and $20,000. Shandong Forward Machinery stands out with a 100% reorder rate, signaling strong client retention despite lower online revenue visibility. Zhengzhou Yugong and Wenzhou Tianyue demonstrate robust customization capabilities, particularly in mold design and automation control parameters. Buyers seeking rapid deployment should prioritize suppliers with ≤2-hour response times and documented experience shipping to Indian ports under FOB or CIF terms.

FAQs

How to verify papad making machine supplier reliability?

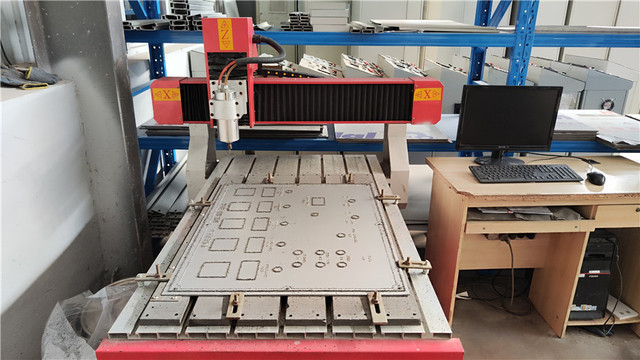

Validate certifications through issuing body databases. Request third-party inspection reports from agencies like SGS or BV covering material composition, safety compliance, and performance testing. Assess factory credibility via video walkthroughs of CNC machining centers and final assembly bays.

What is the typical lead time for fully automatic papad machines?

Standard units ship within 30–45 days after order confirmation. Customized systems with integrated frying or seasoning modules require 50–70 days. Add 10–14 days for sea freight to major Indian ports such as Mumbai or Chennai under FOB terms.

Do suppliers offer customization for Indian market requirements?

Yes, leading suppliers provide configuration options for regional preferences, including turmeric-infused dough handling, circular vs. square shaping molds, and adjustable moisture content settings. Most support 3-phase 380V/50Hz electrical setups compatible with Indian industrial power standards.

Is sample testing available before bulk purchase?

Sample runs are feasible via remote operation or pre-shipment trial batches. Some suppliers offer processed papad samples shipped separately for texture and consistency evaluation. Full machine prototypes are rare but simulation videos and test logs are commonly provided.

What payment and logistics terms are standard?

Common payment structures include 30% advance T/T with balance against B/L copy. Escrow services are recommended for first-time transactions. Most suppliers manage export documentation and container loading, with sea freight being optimal for single-machine shipments due to size and weight constraints.