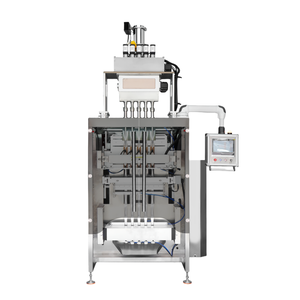

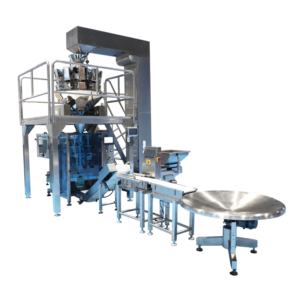

Fully Automatic Chips Packing Machine

Top sponsor listing

Top sponsor listing

About fully automatic chips packing machine

Where to Find Fully Automatic Chips Packing Machine Suppliers?

China remains the dominant hub for manufacturing fully automatic chips packing machines, with key production clusters concentrated in Guangdong and Shandong provinces. These regions host vertically integrated supply chains that support rapid prototyping and large-scale production of packaging automation systems. Foshan and Dongguan in Guangdong are recognized for precision engineering in vertical form-fill-seal (VFFS) machinery, while Jinan in Shandong specializes in compact, high-speed solutions tailored for snack food processors.

The industrial ecosystems in these zones enable suppliers to offer competitive advantages in cost efficiency and lead time reduction. Localized access to CNC machining, servo motor components, and film handling systems reduces material procurement cycles by 20–30%. Buyers benefit from streamlined logistics, with average delivery timelines ranging from 15 to 45 days depending on customization level. The presence of multi-specialty OEMs allows flexible configurations—including nitrogen flushing, multihead weighers, and volumetric cup filling—supporting diverse output requirements from small-batch producers to industrial lines.

How to Choose Fully Automatic Chips Packing Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capabilities

Verify machine specifications align with product characteristics: bag size range (typically 50–250mm width), filling volume (50–1000g), sealing type (back seal, gusseted, or pillow), and integration compatibility with upstream weighing systems. Nitrogen-flushed packaging demands hermetic sealing validation and gas flushing control accuracy within ±2%. Confirm availability of design drawings, PLC interface documentation, and CE certification for compliance with international safety standards.

Production and Customization Capacity

Assess supplier infrastructure based on the following benchmarks:

- Minimum factory area exceeding 2,000m² to support assembly and testing

- In-house R&D teams capable of modifying bag length, film feeding mechanisms, and HMI interfaces

- Proven experience integrating multihead weighers (up to 14 heads) for accurate chip dosing

Cross-reference customization claims with actual product listings showing variations in bag shape, label placement, and volumetric dispensing.

Quality Assurance & Transaction Security

Prioritize suppliers with documented quality management systems and verified performance metrics. On-time delivery rates above 95% and response times under 3 hours indicate operational reliability. Utilize secure payment methods such as escrow services, especially when engaging newer manufacturers. Request sample units to evaluate build quality, sealing consistency, and noise levels during continuous operation before scaling orders.

What Are the Best Fully Automatic Chips Packing Machine Suppliers?

| Company Name | Location | Verification Type | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Product Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Foshan Jintian Packing Machinery Co., Ltd. | Foshan, CN | Custom Manufacturer | US $1,200,000+ | 96% | ≤2h | 33% | Multi-function, filling, labeling, vacuum, volumetric cup | $1,000–$2,600 |

| Dongguan Sammi Packing Machine Co., Ltd. | Dongguan, CN | Multispecialty Supplier | US $380,000+ | 87% | ≤2h | <15% | VFFS, nitrogen flush, weight-based sealing | $530–$1,400 |

| Shantou Kingdom Packaging Co., Ltd. | Shantou, CN | Multispecialty Supplier | US $3,000+ | 100% | ≤7h | 50% | High-speed VFFS, multihead weigher integration | $2,000–$13,000 |

| Dongguan Chengong Machinery Equipment Co., Ltd. | Dongguan, CN | Unverified | US $120,000+ | 87% | ≤3h | <15% | Vertical packaging, multi-lane, powder quantification | $530–$19,999 |

| Jinan Guoqiang Machinery Co., Ltd. | Jinan, CN | Unverified | US $6,000+ | 100% | ≤1h | <15% | Stand-up pouches, tortilla chip packaging, multihead weighers | $3,500–$29,500 |

Performance Analysis

Foshan Jintian stands out for its extensive product portfolio and strong reorder rate, indicating consistent customer satisfaction in both standard and customized builds. Shantou Kingdom demonstrates exceptional reliability with a 100% on-time delivery record and high reorder frequency, despite higher price points reflecting advanced nitrogen and multihead weighing integration. Jinan Guoqiang offers premium solutions targeting specialty applications, including stand-up pouches and tortilla packaging, backed by rapid response capability. While Dongguan-based suppliers provide entry-level affordability, their lower reorder rates suggest potential gaps in post-sale support or long-term durability. For mission-critical deployments, prioritize manufacturers with proven track records in sealed atmosphere packaging and PLC-controlled motion systems.

FAQs

How to verify fully automatic chips packing machine supplier reliability?

Validate certifications (CE, ISO 9001), request facility videos demonstrating live machine testing, and review transaction history for dispute resolution patterns. Analyze customer feedback focusing on after-sales service, spare parts availability, and software interface usability.

What is the typical lead time for standard and custom machines?

Standard models are typically delivered within 15–25 days. Custom configurations involving nitrogen flushing, multi-lane output, or integrated weighers require 30–45 days, depending on complexity and component sourcing.

Do suppliers offer customization options?

Yes, most established manufacturers support modifications in bag dimensions, sealing patterns, film types, and control systems. High-end models allow integration with external conveyors, checkweighers, and date coding equipment. Provide detailed technical drawings or operational parameters to initiate customization.

What is the average minimum order quantity (MOQ)?

The standard MOQ is 1 unit, allowing buyers to test performance before volume procurement. Some suppliers waive setup fees for orders exceeding five units, particularly for customized variants.

Can these machines handle different types of snacks?

Absolutely. Machines are adaptable for potato chips, banana chips, popcorn, nuts, and puffed snacks through adjustable feed mechanisms and programmable logic controllers. Ensure correct feeder and sealing jaw configuration for fragile or irregularly shaped products to minimize breakage and ensure consistent packaging integrity.