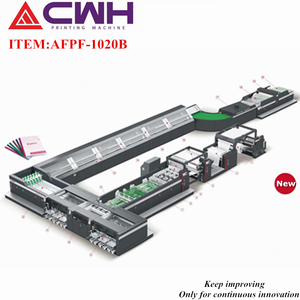

Fully Automatic Notebook Making Machine Price

1/15

1/15

1/16

1/16

CN

CN

1/18

1/18

1/16

1/16

1/12

1/12

CN

CN

1/17

1/17

About fully automatic notebook making machine price

Where to Find Fully Automatic Notebook Making Machine Suppliers?

China remains the dominant hub for manufacturing fully automatic notebook making machines, with key production clusters concentrated in Henan and Jiangsu provinces. Zhengzhou, Henan’s industrial center, hosts multiple specialized manufacturers offering integrated solutions for coil binding, perfect binding, and hardcover notebook production. These regions benefit from mature paper processing ecosystems, including access to raw material suppliers, precision component fabricators, and skilled technical labor, enabling vertically integrated operations that reduce assembly lead times by 20–30% compared to decentralized setups.

The supply chain advantage is further strengthened by proximity to major logistics ports such as Qingdao and Shanghai, facilitating efficient containerized shipping for heavy machinery. Factories in these zones typically operate on a lean production model with monthly output capacities ranging from 15 to 50 units per line, depending on automation level and machine complexity. Buyers gain access to scalable production runs, fast prototyping, and modular design adaptations tailored to regional market demands—particularly for educational, office, and diary products.

How to Choose Fully Automatic Notebook Making Machine Suppliers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify ISO 9001 certification as a baseline for quality management systems. For export to regulated markets (EU, North America), confirm CE marking compliance, particularly for electrical safety (IEC 60204-1) and mechanical guarding standards. Request documentation on motor efficiency ratings, PLC control systems (e.g., Siemens or Mitsubishi), and safety interlock mechanisms.

Production Capability Assessment

Evaluate supplier infrastructure using the following benchmarks:

- Minimum factory area of 3,000m² to support full assembly lines

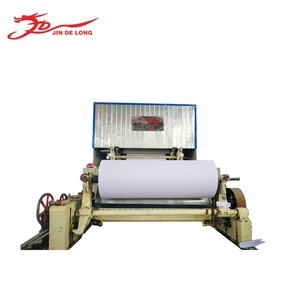

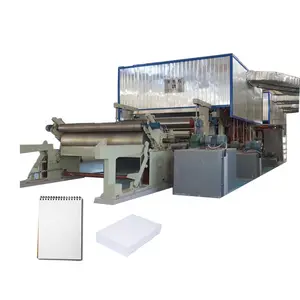

- In-house engineering teams capable of customizing binding width (A3/A4), stitch speed (up to 200 books/hour), and material compatibility (paper weight 60–120gsm)

- Proven experience with servo-driven automation, pneumatic pressing, and hot-melt gluing subsystems

Cross-reference online revenue data and reorder rates to assess commercial stability and customer satisfaction.

Transaction Security & After-Sales Support

Prioritize suppliers offering third-party inspection services (e.g., SGS or TÜV) prior to shipment. Confirm availability of remote troubleshooting via PLC diagnostics and multilingual technical manuals. Assess after-sales response time—ideally under 4 hours—and inquire about spare parts inventory and warranty terms (standard range: 12–24 months).

What Are the Best Fully Automatic Notebook Making Machine Suppliers?

| Company Name | Location | Verified Status | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range (Price Range) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Zomagtc Co., Ltd. | Henan, CN | Custom Manufacturer | US $1.3M+ | 100% | ≤2h | 38% | $4,900–$160,000 | Color, size, logo, packaging, graphic |

| ZOMAGTC CO., LTD | Henan, CN | - | - | - | ≤2h | - | $5,098–$197,142 | Paper Processing, Binding, Post-Press |

| Zhengzhou Allraise Company Ltd. | Henan, CN | Custom Manufacturer | US $580K+ | 100% | ≤2h | 39% | $26,999–$142,857 | Color, size, logo, packaging, graphic |

| Suzhou Ruicai Electron Co., Ltd. | Jiangsu, CN | - | US $160K+ | 96% | ≤10h | <15% | $188–$53,800 | Limited customization |

| Ruian Koten Machinery Co., Ltd. | Zhejiang, CN | Multispecialty Supplier | US $10K+ | - | ≤3h | <15% | $8,000–$190,000 | Semi-auto, color, size, logo |

Performance Analysis

Zhengzhou-based manufacturers dominate in reliability and responsiveness, with both Zomagtc and Allraise achieving 100% on-time delivery and sub-2-hour average response times. These suppliers offer extensive customization and serve mid-to-high-end market segments with machines priced above $25,000. Zhengzhou Zomagtc stands out with the highest reported online revenue ($1.3M+) and strong repeat business (38% reorder rate), indicating consistent performance and client trust.

In contrast, Suzhou Ruicai offers entry-level models starting below $2,000 but exhibits lower reorder rates (<15%) and delayed responses (≤10h), suggesting potential limitations in post-sale support. Ruian Koten provides a broad price spectrum but lacks verified delivery metrics. For high-volume procurement, prioritize suppliers with documented production facilities, ISO certification, and proven export experience to minimize downtime risk and ensure regulatory compliance.

FAQs

What is the typical MOQ and lead time for fully automatic notebook making machines?

Minimum Order Quantity (MOQ) is typically 1 set. Standard lead time ranges from 20 to 45 days after deposit confirmation, depending on machine complexity and customization level. Express production may reduce timelines by 5–10 days at additional cost.

Can suppliers customize machine specifications?

Yes, leading manufacturers offer customization for binding type (spiral, perfect, saddle-stitch), book size (A4, A5, A3), production speed, and interface language. Custom branding, voltage adaptation (380V/50Hz or 220V/60Hz), and PLC integration are commonly available upon request.

Do suppliers provide installation and training support?

Most established suppliers include remote setup guidance via video call. On-site technician deployment is available for an additional fee, typically covering travel and daily rates. Pre-shipment testing reports and operation manuals are standard deliverables.

What payment methods are accepted for large machinery purchases?

Common terms include 30% T/T advance payment with balance before shipment or through Letter of Credit (L/C) at sight. Escrow services are recommended for first-time transactions to mitigate financial risk.

How are machines packaged and shipped internationally?

Machines are securely packed in seaworthy plywood crates with anti-vibration padding. Shipping options include FOB (port of origin) or CIF (delivered to destination port). Air freight is viable for urgent orders of smaller units; sea freight is standard for full-container loads due to weight and dimension constraints.