Fully Automatic Notebook Manufacturing Machine Price

Top sponsor listing

Top sponsor listing

About fully automatic notebook manufacturing machine price

Where to Find Fully Automatic Notebook Manufacturing Machine Suppliers?

China remains the global epicenter for fully automatic notebook manufacturing machine production, with key industrial clusters concentrated in Henan Province. Zhengzhou, the provincial capital, hosts a dense network of machinery manufacturers specializing in paper processing and post-press automation equipment. This region benefits from integrated supply chains for steel fabrication, electrical components, and servo systems, enabling cost efficiencies of 20–35% compared to equivalent machinery produced in Europe or Southeast Asia.

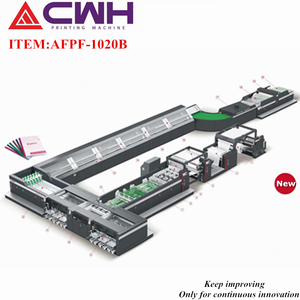

The ecosystem supports both standardized and engineered-to-order solutions, with suppliers offering end-to-end production lines that integrate printing, folding, stitching, cover mounting, and trimming. Vertical integration allows rapid component sourcing and assembly, reducing lead times for standard configurations to 45–60 days. Buyers gain access to scalable manufacturing infrastructures capable of fulfilling single-unit pilot orders up to full container load (FCL) deployments. The proximity of technical engineers, CNC workshops, and logistics providers within a 50-kilometer radius further enhances operational responsiveness.

How to Choose Fully Automatic Notebook Manufacturing Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to international safety and quality standards such as CE marking for electrical systems and ISO 9001 for quality management. Machines intended for export must comply with destination-market regulations regarding noise levels, emergency stop mechanisms, and electrical insulation. Request documentation on motor efficiency ratings, PLC control systems (e.g., Siemens or Mitsubishi), and durability testing protocols for critical components like gripper chains and glue application units.

Production Capability Assessment

Evaluate supplier infrastructure through verifiable metrics:

- Facility size exceeding 3,000m² indicating capacity for large-scale production

- In-house engineering teams capable of customizing machine width (e.g., A4, B5, custom formats), binding types (saddle-stitch, perfect bind, spiral), and material compatibility (paper weight 60–120 gsm, synthetic covers)

- Integration of precision machining (CNC milling, laser cutting) and automated welding for structural rigidity

Cross-reference product listings with on-time delivery performance (target ≥98%) and reorder rates above 40% as indicators of customer satisfaction.

Transaction Risk Mitigation

Utilize secure payment frameworks such as escrow services to align payment milestones with machine commissioning. Prioritize suppliers with documented quality control procedures, including pre-shipment testing reports and video inspections. For high-value orders (> $50,000), conduct remote factory audits via live video walkthroughs to validate production status and component sourcing practices.

What Are the Leading Fully Automatic Notebook Manufacturing Machine Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Zhengzhou Zomagtc Co., Ltd. | Henan, CN | Paper Processing Machinery (1447), Paper Product Making Machinery (965) | 100% | 44% | ≤2h | US $1,400,000+ | Color, material, size, thickness, width, logo, packaging, graphic |

| ZOMAGTC CO., LTD | Henan, CN | Paper Processing Machinery (435), Binding Machine (104) | - | - | ≤2h | - | Not specified |

| Zhengzhou Allraise Company Ltd. | Henan, CN | Paper Processing Machinery, Post-Press Equipment | 100% | 40% | ≤2h | US $590,000+ | Color, material, size, logo, packaging, graphic |

| Henan Allwin Machinery Equipment Co., Ltd. | Henan, CN | Paper Processing Machinery (325), Gluing Machines (40) | 100% | 66% | ≤2h | US $10,000+ | Not specified |

Performance Analysis

Zhengzhou-based suppliers dominate the segment, combining high delivery reliability (100% on-time rate across multiple vendors) with strong customization capabilities. Zhengzhou Zomagtc Co., Ltd. demonstrates extensive market presence with over 1,400 listings in paper processing machinery and verified annual online revenue exceeding $1.4 million, indicating robust order volume and supply chain stability. Henan Allwin stands out with a 66% reorder rate—the highest among peers—suggesting superior post-sale service or machine reliability. While some suppliers lack disclosed financial metrics, consistent sub-2-hour response times reflect operational discipline crucial for resolving technical queries during procurement cycles.

FAQs

What is the typical price range for fully automatic notebook making machines?

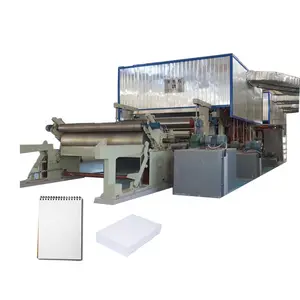

Prices vary significantly based on functionality and output capacity. Entry-level semi-automatic systems start at $3,600–$5,500 per set, while fully integrated A4-sized production lines range from $22,000 to $43,000. High-speed industrial models with multi-functional capabilities (printing, cutting, binding) reach $130,000–$197,000 per unit.

What are common MOQ and lead time expectations?

Most suppliers require a minimum order quantity of 1 set, facilitating pilot procurement. Standard lead times range from 30–45 days after deposit confirmation, depending on machine complexity and customization level. Expedited builds may be available for an additional fee.

Can suppliers customize machines for specific notebook formats?

Yes, leading manufacturers offer configuration options for book size (A4, A5, custom), spine type (glued, stitched, spiral), sheet count (16–120 pages), and cover feeding mechanisms. Custom tooling and PLC programming can be adapted upon request, typically requiring technical drawings or sample specifications.

Do suppliers provide installation and training support?

Many suppliers include remote troubleshooting, operation manuals, and video tutorials. On-site commissioning and technician training are often negotiable, particularly for orders exceeding $50,000. Clarify these terms during contract finalization.

Are spare parts and after-sales service available internationally?

Established exporters maintain inventories of critical spares (grippers, belts, nozzles) and offer replacement part shipping via air freight. Some suppliers provide warranties ranging from 12–24 months on core components, excluding consumables like glue pots and cutting blades.